Industrial Research Institute of Ishikawa

Manufacturing technology for CFRTP stampable sheet by using extrusion lamination method

Manufacturing technology for CFRTP stampable sheet by using extrusion lamination method

- Technical Classification:

- [ Intermediate Products ]

- Products:

- Keyword:

- [ CFRTP ] [ resin impregnating ability ] [ void fraction ]

Point of the Proposed Technology

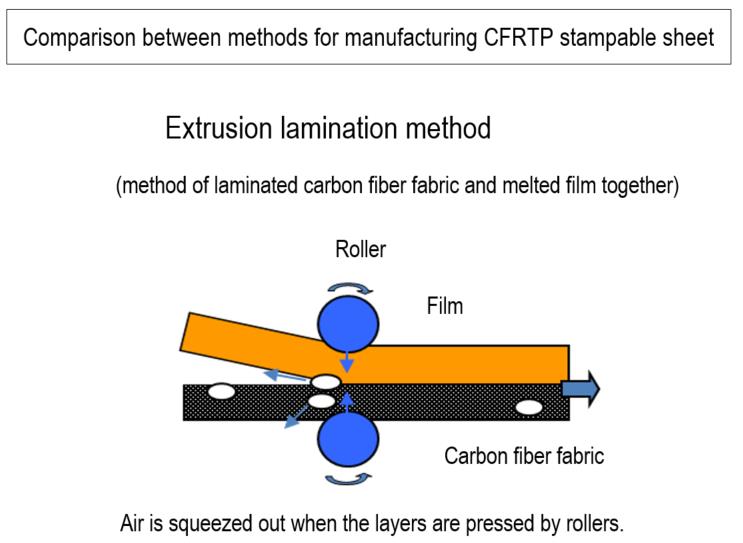

・Technology for laminating a thermoplastic resin film on carbon fiber fabric by using extrusion lamination method

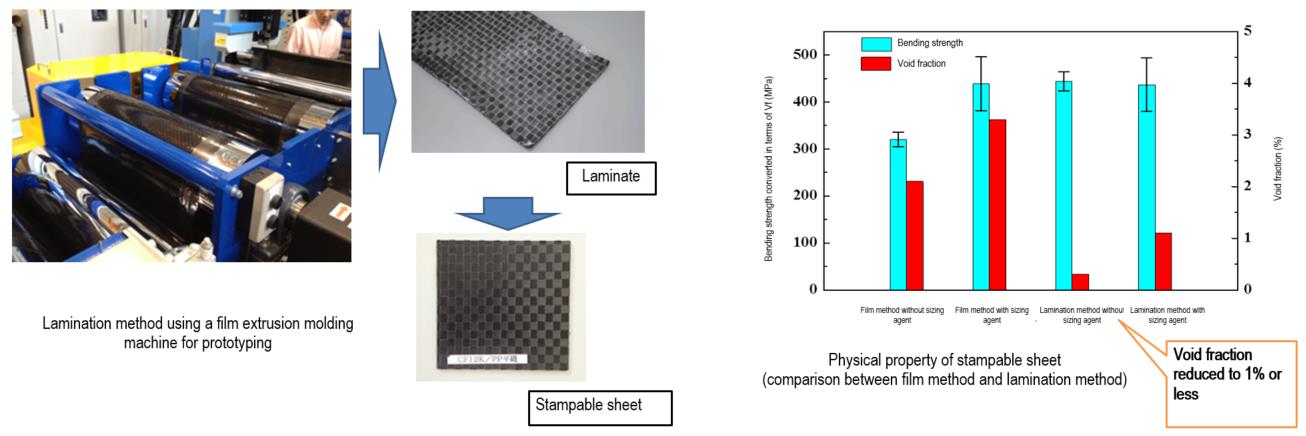

・Achieving improvement of the resin impregnation and reduction of the void fraction by molding a CFRTP plate by the laminate sheets

・Achieving improvement of the resin impregnation and reduction of the void fraction by molding a CFRTP plate by the laminate sheets

Effect(s)

・Improved impregnation

・Reduced void fraction

・Reduced void fraction

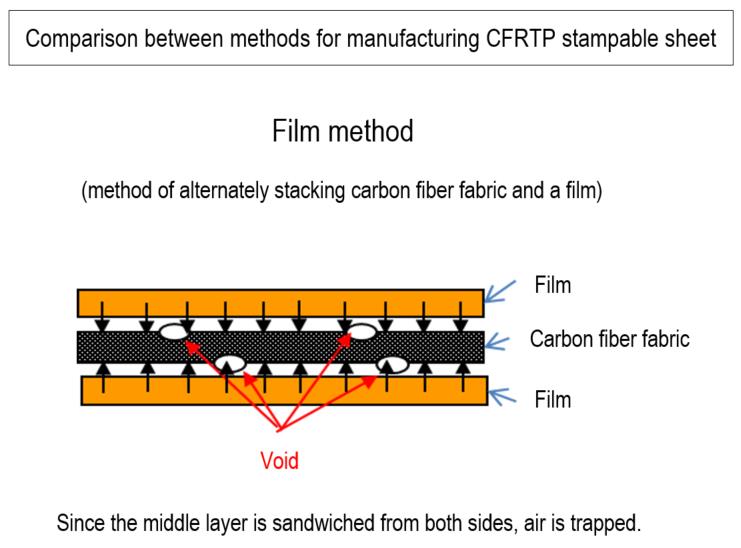

Conventional Technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 2014/3; progress: 100%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Example of Application

- Stampable sheet (intermediate matrix)

- Technical Problems

- ・Use of a thermoplastic resin that can be molded into a film, and fabric–form carbon fiber

・Prototyping conditions: width 500 mm or less, molding temperature 450°C or below

- Collaborator needed to Improve

- Material developing manufacturers, press molding firms

Research and development institutions such as universities that conduct research and development related to CFRTP

- Technical WEB page

- http://www.irii.jp/jisedai/index.html

Inquiries

- Personnel / Department

- Planning/Consultation Department / Researcher, Mitsugu KIMIZU

- Address

- 2-1, Kuratsuki, Kanazawa, Ishikawa Prefecture, 920-8203, Japan

- Contact

-

TEL:+81-76-267-8089

Inquiry Form

Outline of Company and Organization

- Location

- 2-1, Kuratsuki, Kanazawa, Ishikawa Prefecture, 920-8203, Japan

- Contact

-

TEL:+81-76-267-8081

- Capital / No. of Employees

- 0 yen /

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.irii.jp

Update date: 2020/2/7