KURIMOTO,LTD.

Carbon-LFTD system

Carbon-LFTD system

- Technical Classification:

- [ Molding ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ CFRP ] [ discontinuous fiber ] [ high-cycle molding ] [ large parts ] [ mass production ] [ Thermoplastic resin ] [ trial production ]

Point of the Proposed Technology

〇 A molded CFRTP part can be manufactured directly from resin pellets and Roving (fiber) without using an intermediate base material. This is a new CFRTP molding process that achieves substantial reduction of the material cost. It has various dispersing and kneading capabilities, and can also be used for large tows, which are difficult to disperse.

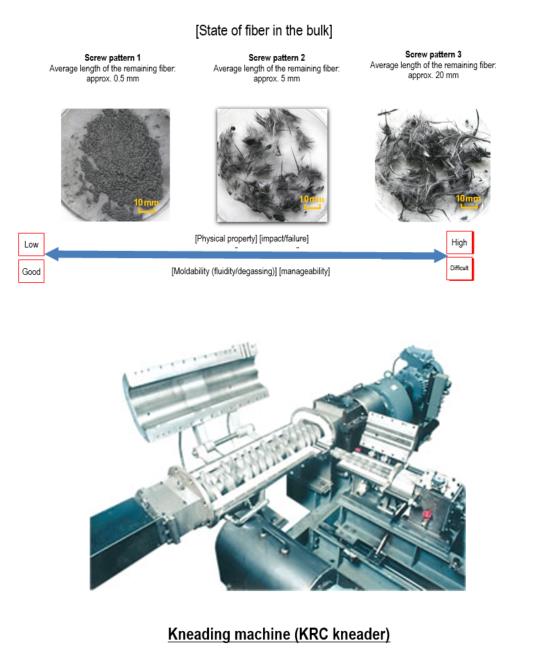

〇 We provide a self-cleaning type kneading machine (KRC kneader) with a low L/D structure, and a high-accuracy, high-cycle hydraulic press (manufactured by WICKERT) which adapts to thermoplastic composite molding. We propose devices and a process that are compact and excel in maintainability.

〇 We provide a self-cleaning type kneading machine (KRC kneader) with a low L/D structure, and a high-accuracy, high-cycle hydraulic press (manufactured by WICKERT) which adapts to thermoplastic composite molding. We propose devices and a process that are compact and excel in maintainability.

Effect(s)

(1) Substantial reduction of the material cost

(2) Mass-production molding

(3) Improvement of molding quality

(4) Reduction of the die cost

(2) Mass-production molding

(3) Improvement of molding quality

(4) Reduction of the die cost

Conventional Technology

(1) An injection molding process that uses an intermediate base material (long-fiber pellets, etc.) as the raw material to be molded. ⇒ material cost

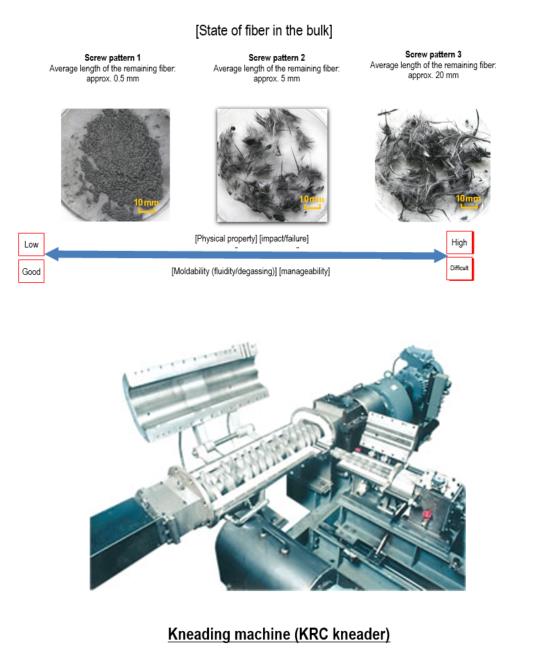

(2) The average length of the remaining fiber in the molded part is approx. 0.3 mm to 3 mm.

(3) For vacuum molding to manufacture a void-less part, a vented or share-edge die structure is applied.

(2) The average length of the remaining fiber in the molded part is approx. 0.3 mm to 3 mm.

(3) For vacuum molding to manufacture a void-less part, a vented or share-edge die structure is applied.

New Technology

● Process

(1) An on-site kneading and molding process that does not require an intermediate base material A press molding process for molding a part directly from resin pellets and Roving fiber (large tow), which are inexpensive in material cost. A press molding process that substantially reduces the material cost and also allows mass-production molding.

(2) Capable of molding at low pressure (approx. 5 MPa). Substantially reduces the equipment cost for molding large-shape parts.

● Kneading (KRC kneader)

(1) By adopting a low L/D biaxial continuous kneading machine (KRC kneader),which has a high dispersion capacity, a system configuration that excels in space saving and maintainability is achieved.

(2) Capable of manufacturing a kneaded product having a fiber length according to the purpose by using various paddle patterns.

● Hydraulic press

A high-accuracy hydraulic press that performs molding while maintaining a micron-order (<25 μm/m) parallelism.

⇒ sustantial improvement of dimensional accuracy.

(1) An on-site kneading and molding process that does not require an intermediate base material A press molding process for molding a part directly from resin pellets and Roving fiber (large tow), which are inexpensive in material cost. A press molding process that substantially reduces the material cost and also allows mass-production molding.

(2) Capable of molding at low pressure (approx. 5 MPa). Substantially reduces the equipment cost for molding large-shape parts.

● Kneading (KRC kneader)

(1) By adopting a low L/D biaxial continuous kneading machine (KRC kneader),which has a high dispersion capacity, a system configuration that excels in space saving and maintainability is achieved.

(2) Capable of manufacturing a kneaded product having a fiber length according to the purpose by using various paddle patterns.

● Hydraulic press

A high-accuracy hydraulic press that performs molding while maintaining a micron-order (<25 μm/m) parallelism.

⇒ sustantial improvement of dimensional accuracy.

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 0/0; progress: 0%)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- None

- Example of Application

- Mass production of molded thermoplastic composite parts for automotive parts

- Technical Problems

- 〇 Development that integrates materials (resin, fiber, etc.), process and FRP molding technology

〇 Providing a series of molding systems from material supply to molded products

- Collaborator needed to Improve

- Resin manufacturers, fiber manufacturers, die manufacturers, molding manufacturers, end users who consider mass production

- Technical WEB page

- https://www.kurimoto.co.jp/composite/solution/clftd.html

Inquiries

- Personnel / Department

- Composite Project Division, Business Planning Department / Manager, Hiroomi Kamano

- Address

- 12-19 Kitahorie, 1-chome, Nishi-ku, Osaka-city, Osaka, 550-8580 Japan

- Contact

-

TEL:+81-6-6686-3234

Inquiry Form

Outline of Company and Organization

- Location

- 12-19 Kitahorie, 1-chome, Nishi-ku, Osaka-city, Osaka, 550-8580 Japan

- Contact

-

TEL:+81-6-6538-7731

- Capital / No. of Employees

- 31,100,000,000 yen / 2137 employees(group)

- Product Line

- Social infrastructures (pipes and valves), industrial machinery, construction materials, etc.

- Major Customers

- Many

- Overseas Base(s)

- Europe, Asia

- Certification

- Company/Organization WEB page

- http://www.kurimoto.co.jp/

Update date: 2020/2/18