Neos Company Ltd.

Water-based mold release agent with excellent secondary workability performance

Water-based mold release agent with excellent secondary workability performance

- Technical Classification:

- [ Molding ] [ Processing ] [ Joining ] [ Painting ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ CFRP ] [ mold release agent ] [ molding ] [ water-based ]

Point of the Proposed Technology

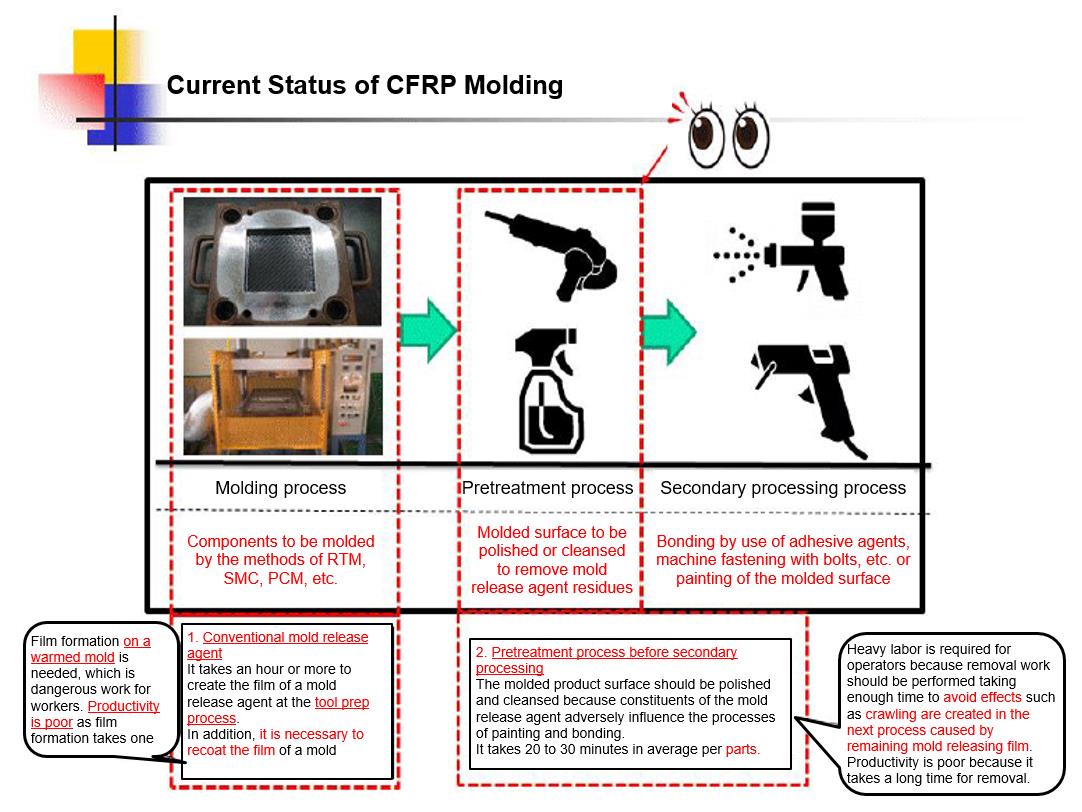

1) Excellent mold release performance comparable to a cured-film mold release agent.

2) Low residues lead to little mold cloudiness and enable tp extend mold cleaning cycle.

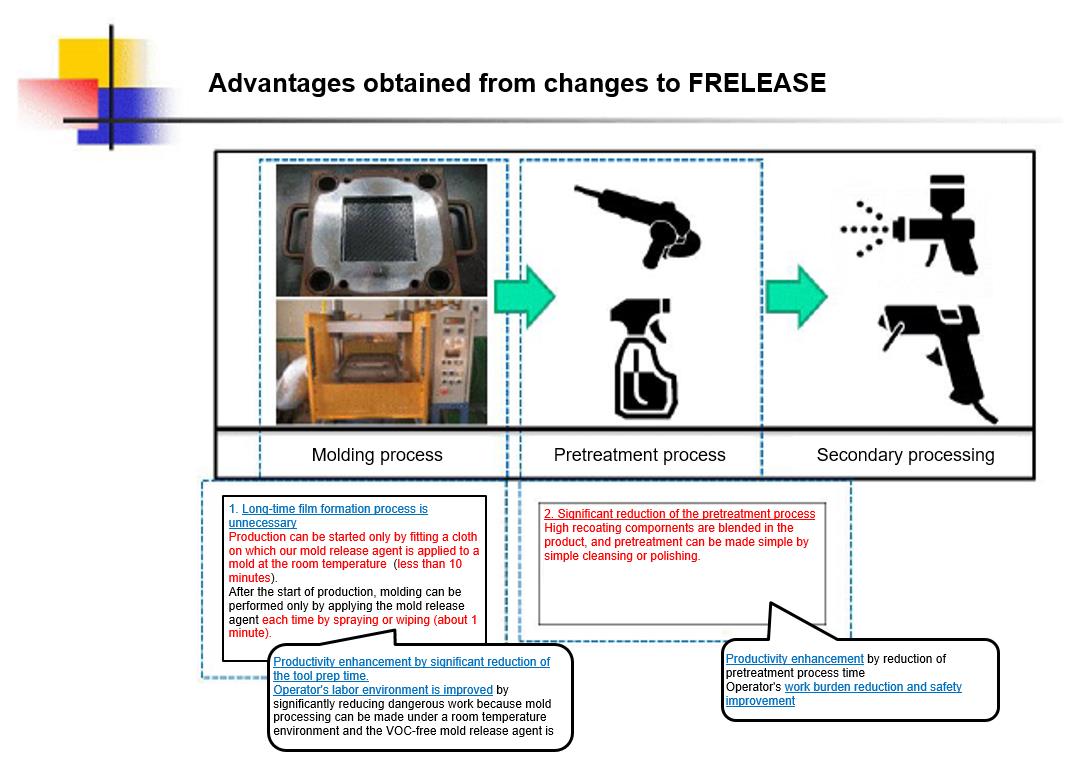

3) Cure processing of mold releasing films at tool prep process is not neccessary , and easy to start molding by applying release agent to the mold by spray or wiping.

4) Significant time reduction is possible in pre treatment process before painting or bonding process due to less transcription to a molded product.

5) Work environment improvement is realized by a mold release agent of the environment-compatible type having significantly small amounts of VOC constituents and being excellent in atmospheric environment preservation.

2) Low residues lead to little mold cloudiness and enable tp extend mold cleaning cycle.

3) Cure processing of mold releasing films at tool prep process is not neccessary , and easy to start molding by applying release agent to the mold by spray or wiping.

4) Significant time reduction is possible in pre treatment process before painting or bonding process due to less transcription to a molded product.

5) Work environment improvement is realized by a mold release agent of the environment-compatible type having significantly small amounts of VOC constituents and being excellent in atmospheric environment preservation.

Effect(s)

Average reduction of 70% or more of the time spent for curing mold releasing film at the tool-prep process in comparison with conventional products.

Reduction of 50% or more of the time at the pretreatment process before painting and bonding in comparison with a conventional cured-film mold release agent

Extension of the mold cleaning cycle

Reduction of 50% or more of the time at the pretreatment process before painting and bonding in comparison with a conventional cured-film mold release agent

Extension of the mold cleaning cycle

Conventional Technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Joint Researchers (their role)

- Example of Application

- The automotive sector, the aviation (interior finishing) sector

- Technical Problems

- Quantification and data base compilation of the secondary processing effect

- Collaborator needed to Improve

- Paint manufacturers, adhesive manufacturers, intermediate base-material manufacturers

- Technical WEB page

- https://www.neos.co.jp/product/mold_release/frelease.html

Inquiries

- Personnel / Department

- Chemical Business Management Dept, Business Planning Sect. / Specialty Chemicals Marketing Expert, Yuta Izaki

- Address

- Kobekanden Bldg. 6-2-1 Kano-cho, Chuo-ku, Kobe-shi, Hyogo, 650-0001 Japan

- Contact

-

TEL:+81-78-331-9382

FAX:+81-78-331-9319

Inquiry Form

Outline of Company and Organization

- Location

- Kobekanden Bldg. 6-2-1 Kano-cho, Chuo-ku, Kobe-shi, Hyogo, 650-0001 Japan

- Contact

-

TEL:+81-78-331-9381

FAX:+81-78-331-9318

- Capital / No. of Employees

- 409,750,000 yen / 298 employees (as of October 2019)

- Product Line

- Fluorine-based surfactant, fluorine-based mold release agents, cutting and grinding agents, cleaning agents, paint removers, rust-preventive agents, dispersants for oil spill, etc.

- Major Customers

- Overseas Base(s)

- China (Shanghai, Guangzhou, Liyang), Singapore, Thailand (Bangkok)

- Certification

- ISO9001, ISO14001

- Company/Organization WEB page

- https://www.neos.co.jp/

Update date: 2020/2/25