Tsuchiya Co., Ltd.

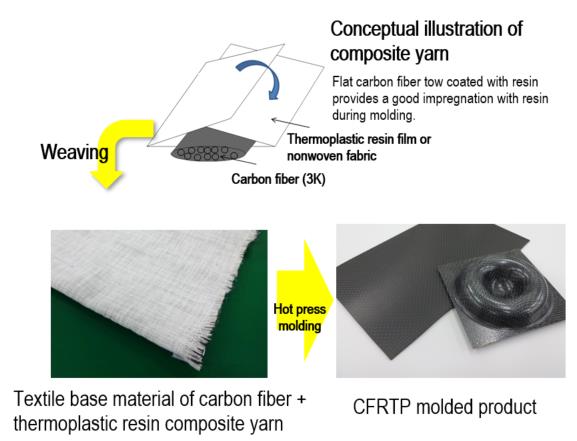

Reduction in the manufacturing cost and improvement of three-dimensional moldability by using the textile base material of the composite yarn of carbon fiber and resin reduces

Reduction in the manufacturing cost and improvement of three-dimensional moldability by using the textile base material of the composite yarn of carbon fiber and resin reduces

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ CFRTP ] [ composite yarn ] [ textile base material ]

Point of the Proposed Technology

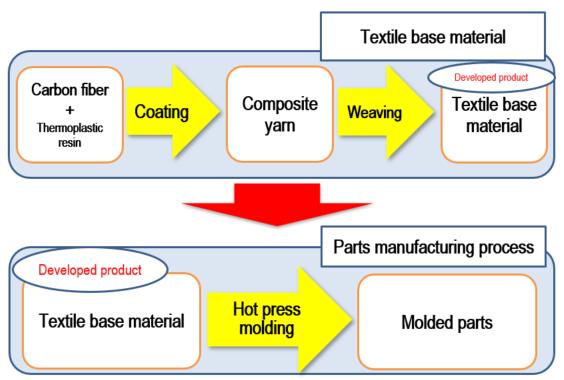

・CFRTP part can be molded directly from the textile base material, and no manufacturing process of CFRTP prepreg is required.

・It can be woven by a general-purpose weaving machine, and it can apply to various weaving conditions corresponding to needs at low cost.

・Since the textile base material has a plasticity, it easily follows to the molding die and can be used for a complicated three-dimensional molding.

・It can be woven by a general-purpose weaving machine, and it can apply to various weaving conditions corresponding to needs at low cost.

・Since the textile base material has a plasticity, it easily follows to the molding die and can be used for a complicated three-dimensional molding.

Effect(s)

・15% reduction of material cost

・Good three-dimensional moldability

・Good three-dimensional moldability

Conventional Technology

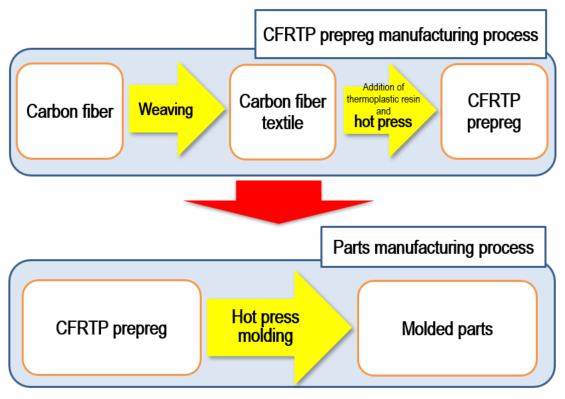

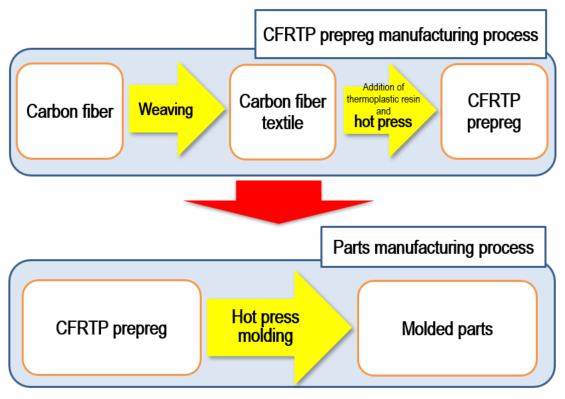

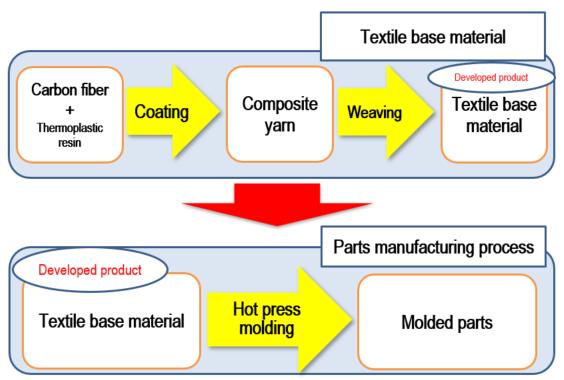

◇Conventional CFRTP parts manufacturing process

・Two hot press processes, in prepreg manufacturing and parts manufacturing, are required.

・Since prepreg is a plate material, it is difficult to mold into a complicated three-dimensional form.

・Two hot press processes, in prepreg manufacturing and parts manufacturing, are required.

・Since prepreg is a plate material, it is difficult to mold into a complicated three-dimensional form.

New Technology

◇CFRTP parts manufacturing process for the developed product

・The textile base material can be manufactured by a general-purpose weaving machine. (Cost reduction)

・ It is woven and has a plasticity, providing a good three- dimensional moldability.

・The textile base material can be manufactured by a general-purpose weaving machine. (Cost reduction)

・ It is woven and has a plasticity, providing a good three- dimensional moldability.

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 2020/3; progress: 70%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Aichi Center for Industry and Science Technology

・Owari Textile Research Center (study of the manufacturing conditions for composite yarn)

・Mikawa Textile Research Center (study of the weaving conditions of textile)

- Example of Application

- ・Parts for automobiles and aircrafts

・Enclosures for OA equipment and medical devices

- Technical Problems

- ・Optimization of composite yarn manufacturing conditions (proportion of fiber and resin, etc.)

・It is molded directly from textile (raw material), and therefore, a high molding pressure (about 20 MPa) is needed to impregnate carbon fiber with resin.

・Sale as a material (textile base material) has been under consideration.

- Collaborator needed to Improve

- ・Processing manufacturers having expertise in CFRTP three-dimensional molding

・Institutions including universities having CFRTP performance assessment technologies/equipment

- Technical WEB page

- http://www.tsuchiya-group.co.jp

Inquiries

- Personnel / Department

- Research and Technology Development Division / Takuya Kojima

- Address

- 22-4, Higashinamikikita, Yama-machi, Chiryu-City, 472-0006, Japan

- Contact

-

TEL:+81-566-83-2121

Inquiry Form

Outline of Company and Organization

- Location

- 9-29, Kamimaezu 2-chome, Naka-ku, Nagoya-City 460-8330 Japan

- Contact

-

TEL:+81-52-331-5451

FAX:+81-52-332-4321

- Capital / No. of Employees

- 100,000,000 yen / 497 employees

- Product Line

- Automobile-related parts (development/manufacturing/selling)

- Major Customers

- Toyota Motor Corporation, etc.

- Overseas Base(s)

- China, Southeast Asia, US, Canada, Czech

- Certification

- ISO14001、ISO9001

- Company/Organization WEB page

- http://www.tsuchiya-group.co.jp

Update date: 2020/1/31