Gifu Prefectural Industrial Technology Center

3D molding technology for CFRTP

3D molding technology for CFRTP

- Technical Classification:

- [ Molding ]

- Products:

- Keyword:

- [ 3D molding technology ] [ CFRTP ] [ press molding ]

Point of the Proposed Technology

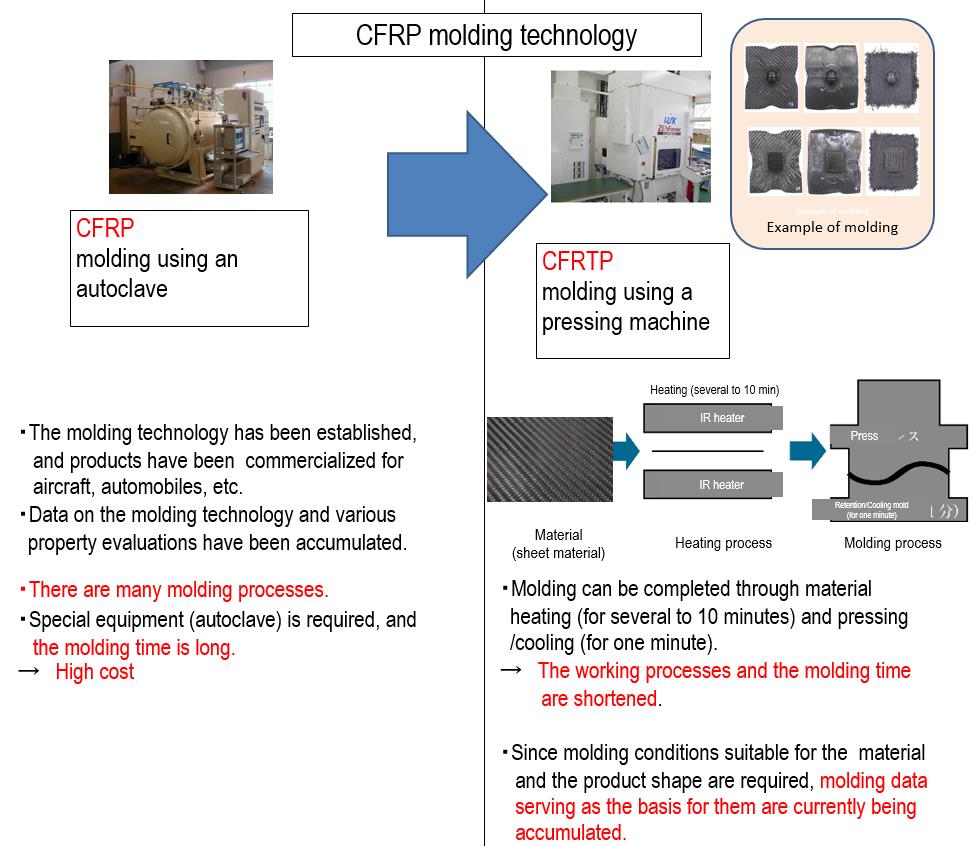

・Basic data on methods for molding (press molding) CFRTP in a 3D shape in place of the conventional CFRTS (autoclave molding), setting conditions and molding evaluation method have been accumulated.

・The institute can provide support based on accumulated data for technological development at companies considering commercialization of CFRTP.

・The institute can provide support based on accumulated data for technological development at companies considering commercialization of CFRTP.

Effect(s)

・Technological support to companies newly working on commercialization of CFRTP

・Spreading of the CFRTP molding technology

・Spreading of the CFRTP molding technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 2016/3; progress: 100%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Industrial Technology Center, Gifu Prefectural Government

(role: development of CFRTP sheetmaterial)

- Example of Application

- ・Automobile parts ・Parts of various transport machines ・Blades for wind power generation・Sporting goods

・Home electronic products ・Commodities

- Technical Problems

- ・Basic technologies on 3D molding of CFRTP are being accumulated. Will enlist cooperation with related companies considering commercialization, and provide technological support to them.

・Currently, the molding data are only for limited on-the-shelf materials. Therefore, any other available materials will be added to the accumulated data in the future.

- Collaborator needed to Improve

- ・Research institutes such as universities having evaluation technology and equipment for moldings’ residual stress and product strength

- Technical WEB page

Inquiries

- Personnel / Department

- Next-Generation Technology Division / Yasuo Doke, Michiaki Sengoku

- Address

- 1288 Oze, Seki-Shi, Gifu, 501-3265 Japan

- Contact

-

TEL:+81-575-22-0147

FAX:+81-575-24-6976

Inquiry Form

Outline of Company and Organization

- Location

- 1288 Oze, Seki-Shi, Gifu, 501-3265 Japan

- Contact

-

TEL:+81-575-22-0147

FAX:+81-575-24-6976

- Capital / No. of Employees

- 0 yen /

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.gitec.rd.pref.gifu.jp/

Update date: 2020/3/5