DENKENSHA Co., Ltd.

Integrated production system for high-strength and high-quality CFRP products

Integrated production system for high-strength and high-quality CFRP products

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ 3D laser scanner ] [ autoclave ] [ CFRP ] [ clean room ] [ thermosetting ] [ ultrasonic flaw inspection ]

Point of the Proposed Technology

Manufacturing of high-strength and high-quality CFRP products

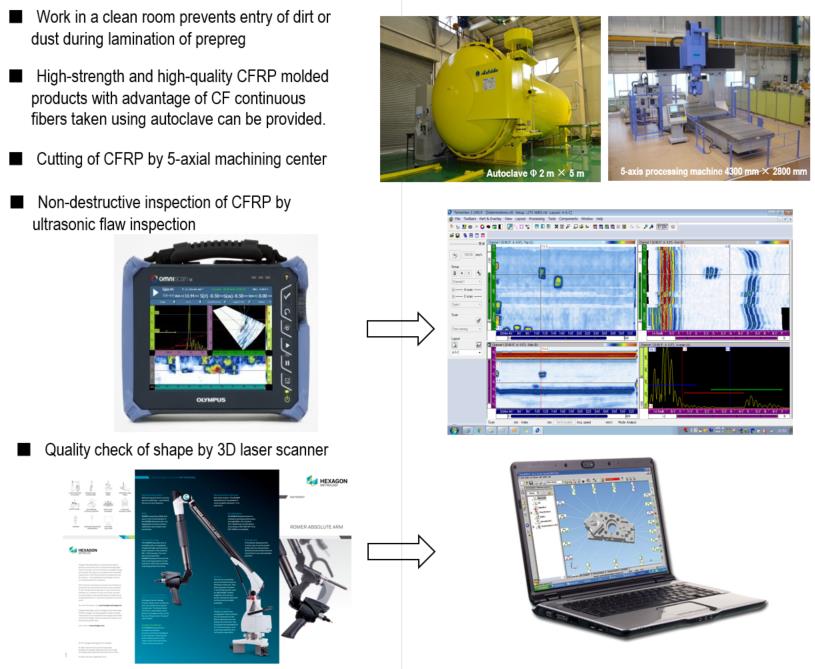

Cutting and lamination of prepreg are performed in a clean room (Class 100000) and thermoset molding is performed by autoclave. Non-destructive inspection can be performed by ultrasonic flaw inspection for checking the quality of finished CFRP.

In addition, the quality of curved surface shape can be checked by non-contact 3D laser scanner. (Possess an electron microscope and image size inspection device)

Cutting and lamination of prepreg are performed in a clean room (Class 100000) and thermoset molding is performed by autoclave. Non-destructive inspection can be performed by ultrasonic flaw inspection for checking the quality of finished CFRP.

In addition, the quality of curved surface shape can be checked by non-contact 3D laser scanner. (Possess an electron microscope and image size inspection device)

Effect(s)

CFRP molded products having guaranteed quality can be provided.

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- On our own

- Example of Application

- General industrial machine parts, medical equipment parts, sports related, automobile parts, aerospace parts

- Technical Problems

- None

- Collaborator needed to Improve

- None

- Technical WEB page

- http://www.denkensha.co.jp/cfrp/

Inquiries

- Personnel / Department

- Engineering Department / Manager, Kenichi Hatabe

- Address

- 2-5-7, Nishitemma, Kita-Ku, Osaka, 530-0047 Japan

- Contact

-

TEL:+81-6-6367-7071

FAX:+81-6-6367-7079

Inquiry Form

Outline of Company and Organization

- Location

- 2-5-7, Nishitemma, Kita-Ku, Osaka, 530-0047 Japan

- Contact

-

TEL:+81-6-6367-7070

FAX:+81-6-6367-7075

- Capital / No. of Employees

- 95,000,000 yen / 65 employees

- Product Line

- CFRP molding, extrusion and injection molding, steel wire processing

- Major Customers

- Overseas Base(s)

- None

- Certification

- ISO 9001/(JIS-Q-9100 Expected to obtain in July, 2018)

- Company/Organization WEB page

- http://www.denkensha.co.jp/

Update date: 2020/2/2