Kajirene Inc.

Commingled Yarn and Tape to enable various textile TP composites

Commingled Yarn and Tape to enable various textile TP composites

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ CFRTP ] [ fibrous intermediate material ] [ Prepreg tape ] [ Textile composite ] [ Thermoplastic matrix ]

Point of the Proposed Technology

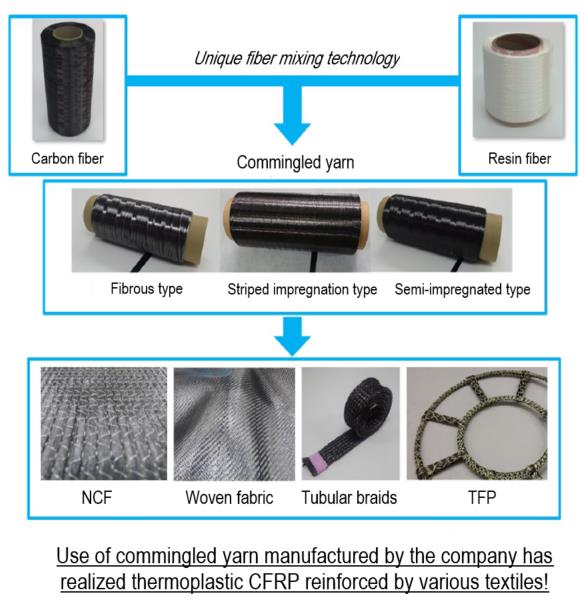

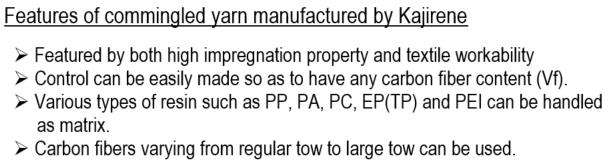

1. A kind of prepreg for CFRTP, "Commingled yarn" and "Commingled tape"

2. These prepregs have both suprerior impregnation property" and "textile-process ability"

3. These prepregs enabled producing various textile preforms for CFRTP.

2. These prepregs have both suprerior impregnation property" and "textile-process ability"

3. These prepregs enabled producing various textile preforms for CFRTP.

Effect(s)

Strength: approx. 2 GPa (using PA, UD reinforcement)

Molding time: 5 min or less (1 mm thick molding)

Molding time: 5 min or less (1 mm thick molding)

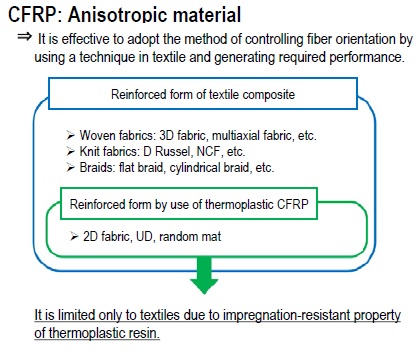

Conventional Technology

New Technology

Video of the Proposed Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Mitsubishi Gas Chemical Company, Inc. (role: resin fiber development and evaluation)

Gifu University (role: molding method development and evaluation)

- Example of Application

- ・Primary and secondary structural members of automobiles

・Socket parts of prostheses

- Technical Problems

- Products will be provided in fibrous, striped impregnation or semi-impregnated commingled yarns.

Standard materials are 6k or a combination of 12k carbon fibers and PA resin (MXD10).

In addition to the above, various types of resin such as PP, PE, PA, PC, EP(TP) and PEI have been used.

- Collaborator needed to Improve

- ・Companies related to press, etc. having knowledge on molding technology

・Companies which can jointly develop solutions with CFRTP members

- Technical WEB page

- http://www.kajigroup.co.jp/

Inquiries

- Personnel / Department

- Group New Business Promotion Department / Toshihiro Motochika

- Address

- NO-75-2 Takamatsu, Kahoku-shi, Ishikawa 929-1215 Japan

- Contact

-

TEL:+81-76-281-0118

FAX:+81-76-281-0164

Inquiry Form

Outline of Company and Organization

- Location

- NO-75-2 Takamatsu, Kahoku-shi, Ishikawa 929-1215 Japan

- Contact

-

TEL:+81-76-281-0118

FAX:+81-76-281-0164

- Capital / No. of Employees

- 25,000,000 yen / 86 employees

- Product Line

- Synthetic fabric for clothing, fabric for industrial materials

- Major Customers

- Asahi Kasei Fibers Corp.

- Overseas Base(s)

- None

- Certification

- Company/Organization WEB page

- http://www.kajigroup.co.jp/

Update date: 2020/2/12