The MOT Company Ltd.

Technology for achieving mass production of thermosetting and thermoplastic CFRP in press molding

Technology for achieving mass production of thermosetting and thermoplastic CFRP in press molding

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ die ] [ heating & cooling ] [ mass production ] [ press molding ]

Point of the Proposed Technology

Short-time molding of thermosetting and thermoplastic CFRP through servo press control

Shortening the molding time by using die and heating/cooling equipment

Cost and production scale for achieving mass production

Shortening the molding time by using die and heating/cooling equipment

Cost and production scale for achieving mass production

Effect(s)

Molding time: one minute (per 1 mm in thickness):

Thermosetting CFRP: 1 minute

Thermoplastic CFRP: 2 minutes

Thermosetting CFRP: 1 minute

Thermoplastic CFRP: 2 minutes

Conventional Technology

[Failure in press molding of thermosetting/thermoplastic CFRP]

Carbon fiber manufacturers made a shift to thermoplastic CFRP (CFRTP) because the thermosetting CFRP (CFRTP) press could not solve the molding problem. However, the molding problem is also unresolved with thermoplastic CFRP, and is inferior to thermosetting with proven track record of mounting aircraft parts in terms of data reliability.

(1) Unsolved problems

(i) Molding time: 10 minutes per 1 mm in thickness

(ii) Shape: complex shape is difficult to mold

(iii) Surface: a liquid will pool on the surface and it will become bleached

(iv) Appearance: loosening texture occurs in the R section

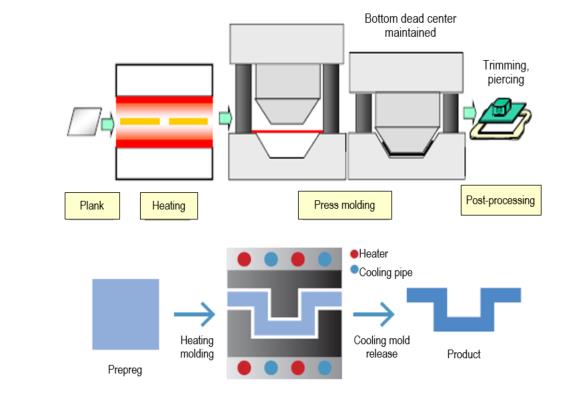

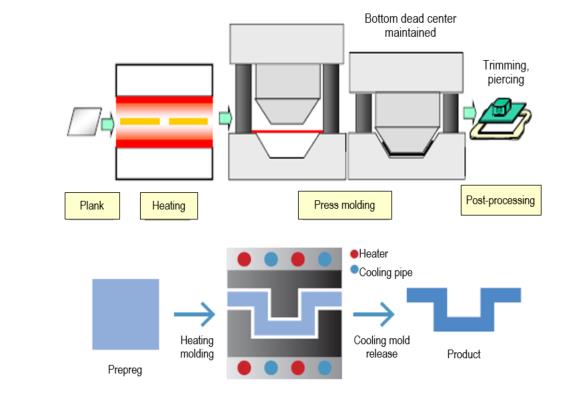

(2) The cause of failure is the hot stamping molding method (upper illustration) and the water flow cooling circuit method (lower illustration).

Incorporating the method which was done by high strength steel sheet, material was heated and molded by cold pressing. Heating and cooling is done by the heating/cooling method, but the cycle time of heating → cooling → demolding → reheating takes too long time.

Carbon fiber manufacturers made a shift to thermoplastic CFRP (CFRTP) because the thermosetting CFRP (CFRTP) press could not solve the molding problem. However, the molding problem is also unresolved with thermoplastic CFRP, and is inferior to thermosetting with proven track record of mounting aircraft parts in terms of data reliability.

(1) Unsolved problems

(i) Molding time: 10 minutes per 1 mm in thickness

(ii) Shape: complex shape is difficult to mold

(iii) Surface: a liquid will pool on the surface and it will become bleached

(iv) Appearance: loosening texture occurs in the R section

(2) The cause of failure is the hot stamping molding method (upper illustration) and the water flow cooling circuit method (lower illustration).

Incorporating the method which was done by high strength steel sheet, material was heated and molded by cold pressing. Heating and cooling is done by the heating/cooling method, but the cycle time of heating → cooling → demolding → reheating takes too long time.

New Technology

[Success in press forming of thermosetting/thermoplastic CFRP]

Instead of hot stamping, the heating/cooling method by which the die is heated and cooled is adopted. There are three technical improvements.

(i) Control of the motion of the servo press

(ii) The method of heating and cooling mold release (cooling air spraying)

(iii) Die design

[Achievements in development]

(i) Molding time: 1 minute (per 1 mm in thickness)

(ii) Applicable to both thermosetting and thermoplastic CFRP

(iii) Mass production cost possible

(iv) Mass production scale possible

(v) Three-dimensional shape possible

Instead of hot stamping, the heating/cooling method by which the die is heated and cooled is adopted. There are three technical improvements.

(i) Control of the motion of the servo press

(ii) The method of heating and cooling mold release (cooling air spraying)

(iii) Die design

[Achievements in development]

(i) Molding time: 1 minute (per 1 mm in thickness)

(ii) Applicable to both thermosetting and thermoplastic CFRP

(iii) Mass production cost possible

(iv) Mass production scale possible

(v) Three-dimensional shape possible

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- None

- Example of Application

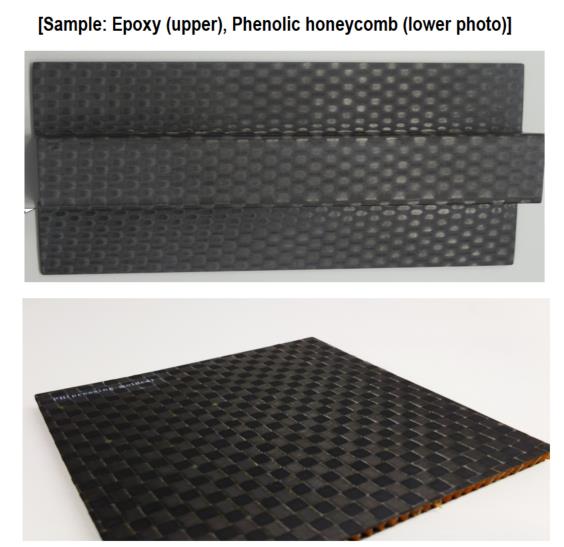

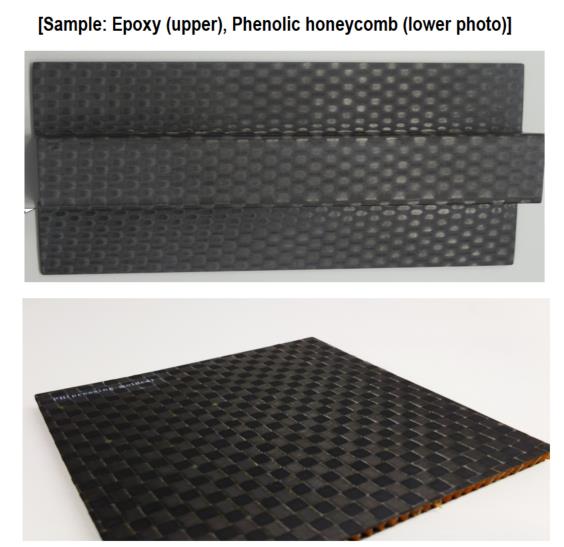

- CFRP parts are adopted for multiple purposes such as those for aircraft, automobile and drone in terms of mass production cost and scale.

- Technical Problems

- Drawing shape is possible.

Molding size is about 1000 mm × 1000 mm, the thickness is about 5 mm at a maximum.

- Collaborator needed to Improve

- Aircraft interior part companies, automobile companies

- Technical WEB page

- http://www.mot-company.com/works.html

Inquiries

- Personnel / Department

- CFRP Division / CEO, Tomoaki Saito

- Address

- 2-3-8 Chidori, Ohta-ku, Tokyo, 146-0083 Japan

- Contact

-

TEL:+81-3-3757-5255

FAX:+81-3-3757-5258

Inquiry Form

Outline of Company and Organization

- Location

- 2-3-8 Chidori, Ohta-ku, Tokyo, 146-0083 Japan

- Contact

-

TEL:+81-3-3757-5255

FAX:+81-3-3757-5258

- Capital / No. of Employees

- 10,000,000 yen / 10 employees

- Product Line

- CFRP-made aircraft parts, racing car parts

- Major Customers

- M-TEC, Toray Carbon Magic Co., Ltd., Tokyo R&D Composite Co., Ltd.

- Overseas Base(s)

- Shanghai

- Certification

- ISO9100

- Company/Organization WEB page

- http://www.mot-company.com/

Update date: 2020/2/18