Suncorona Oda Co., Ltd.

Isotropic CFRTP Stampable Sheet (CF / Thermoplastic Resin)

Isotropic CFRTP Stampable Sheet (CF / Thermoplastic Resin)

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ carbon fiber ] [ Isotropic Stampable Sheet ] [ molding ] [ Thermoplastic resin ]

Point of the Proposed Technology

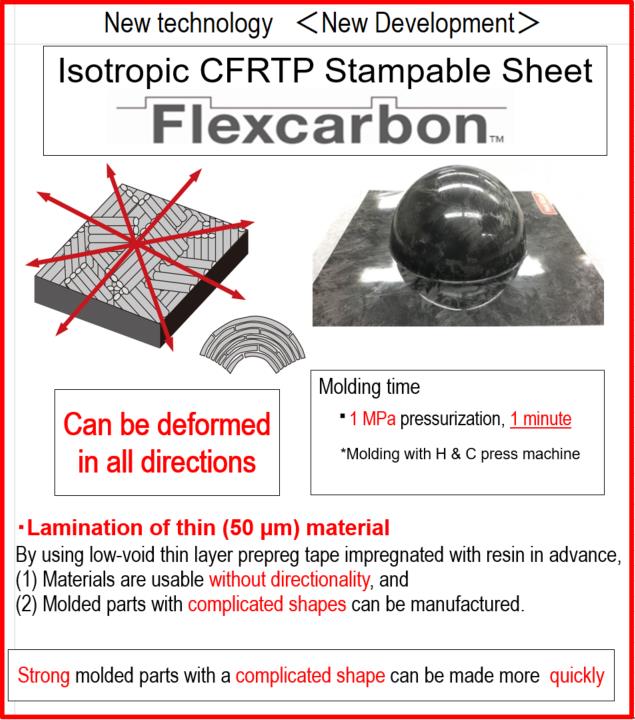

I. Materials with isotropy and high strength (mechanical properties)

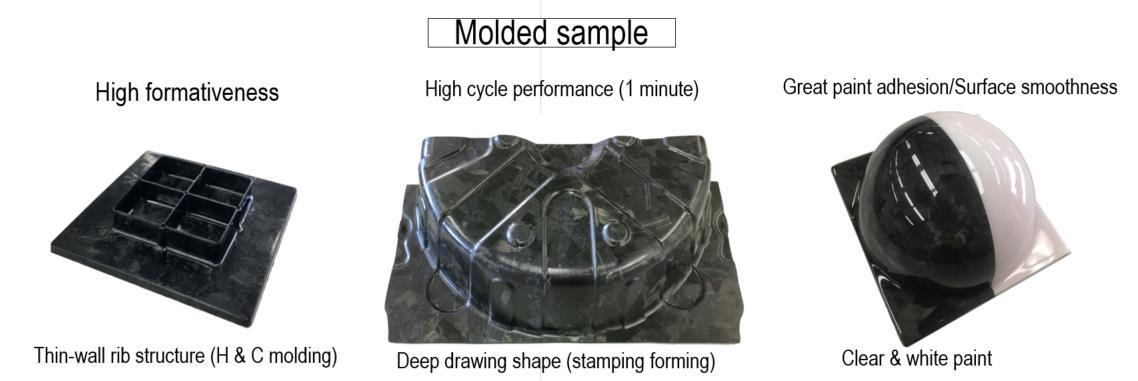

II. High moldability enables to produce intricate-shaped moldings.

III. Short-cycle forming and low-pressure pressing are possible.

IV. A low porosity rate ensures high quality moldings.

V. Suitable for thin CFRP products

II. High moldability enables to produce intricate-shaped moldings.

III. Short-cycle forming and low-pressure pressing are possible.

IV. A low porosity rate ensures high quality moldings.

V. Suitable for thin CFRP products

Effect(s)

Total cost is reduced by shortening the forming time and simplifying the material handling.

Mass: 1/4 of iron or steel

Productivity/workability: high-cycle forming

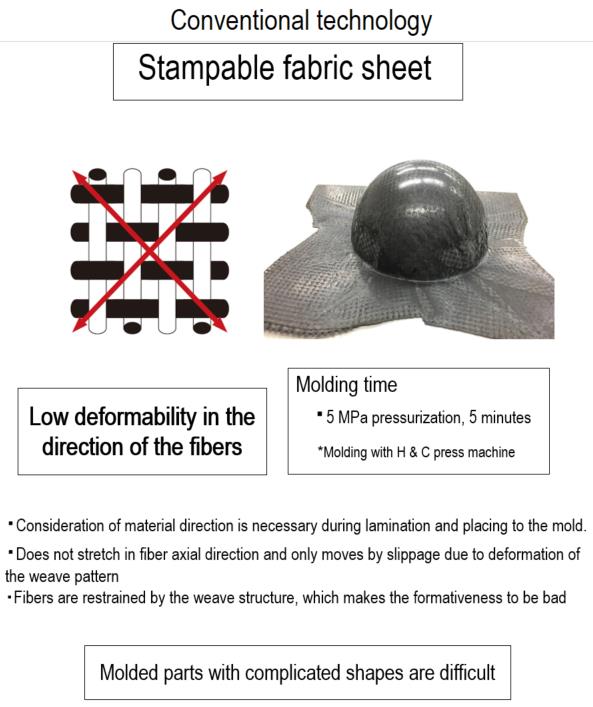

Superior to conventional fabrics in formativeness in deep grooves and small corner radius

Mass: 1/4 of iron or steel

Productivity/workability: high-cycle forming

Superior to conventional fabrics in formativeness in deep grooves and small corner radius

Conventional Technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: no)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Kanazawa Institute of Technology (continuous molding technology)

Industrial Research Institute of Ishikawa (after-processing technology, evaluation of molding products)

- Example of Application

- Metallic parts, thermosetting resin parts. Fabric-made parts that are Difficult to form.

Automotive parts, sports goods.

- Technical Problems

- [Challenge] Developing a cold-pressing molding method and heat-and-cool molding method.

[How to respond] We'll evaluate in collaboration with Kanazawa Institute of Technology and molding processing manufacturer. (Heat&Cool, Stamping forming method)

- Collaborator needed to Improve

- Company that has a molding technology for carbon fiber composites and creates a new market by conducting molding as the end customer

- Technical WEB page

- http://www.sunoda.co.jp/product/new.html

Inquiries

- Personnel / Department

- New Business Development Department / Director, Soichiro Oda

- Address

- Ka-81, Kiba-machi, Komatsu-shi, Ishikawa, 923-0311, Japan

- Contact

-

TEL:+81-761-43-2268

FAX:+81-761-43-1762

Inquiry Form

Outline of Company and Organization

- Location

- Ka-81, Kiba-machi, Komatsu-shi, Ishikawa, 923-0311, Japan

- Contact

-

TEL:+81-761-43-2211

FAX:+81-761-43-1762

- Capital / No. of Employees

- 33,730,000 yen / 167 employees

- Product Line

- Manufactured fiber products

- Major Customers

- Teijin, Toray, NITORI

- Overseas Base(s)

- China, Vietnam

- Certification

- ISO 9001:2008、 JIS Q9001:2008

- Company/Organization WEB page

- http://www.sunoda.co.jp

Update date: 2020/2/12