Gifu Prefectural Industrial Technology Center

3D molding technologies for thermoplastic CFRP laminates

3D molding technologies for thermoplastic CFRP laminates

- Technical Classification:

- [ Intermediate Products ]

- Products:

- Keyword:

- [ 3D molding ] [ knitted material ] [ Thermoplastic CFRP ]

Point of the Proposed Technology

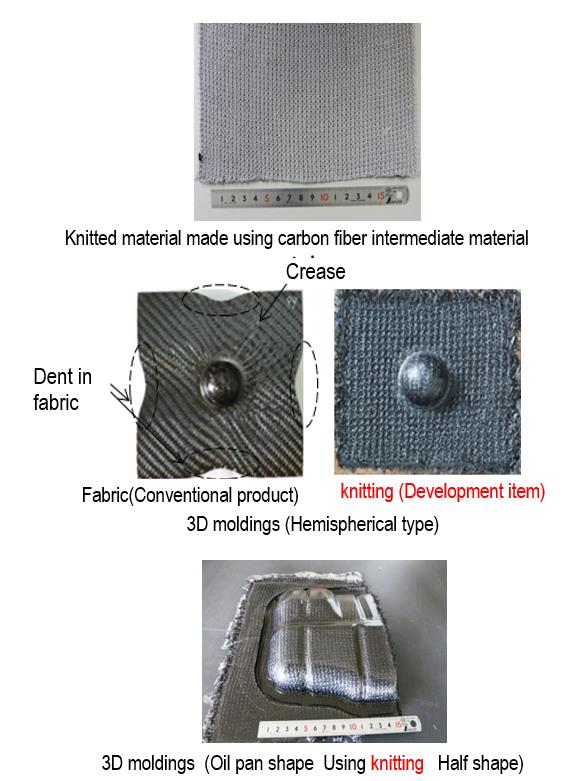

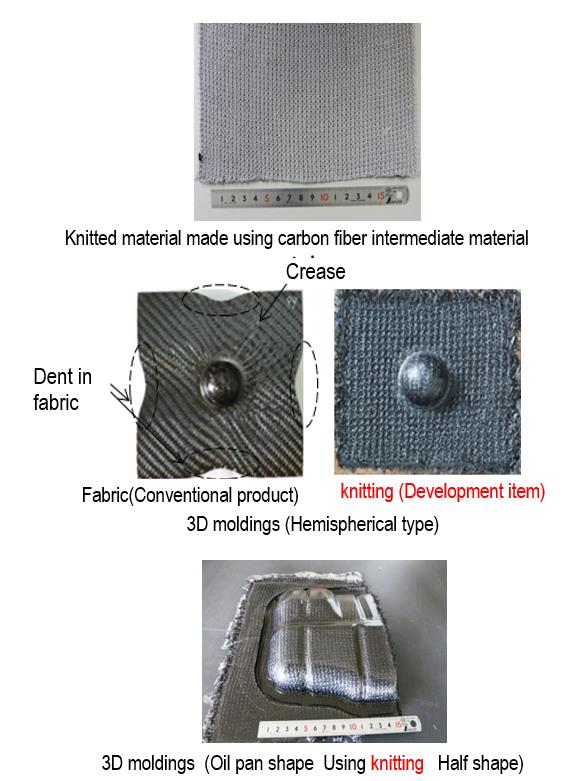

Previously, in 3D molding a thermoplastic CFRP laminate, there was a problem that a laminate using fabric material as the base material is subject to creasing because of lack of elasticity. By developing a laminate using knitted material as the base material, a CFRP laminate with excellent forming capabilities can be acquired.

Effect(s)

3D moldings of thermoplastic CFRP

Conventional Technology

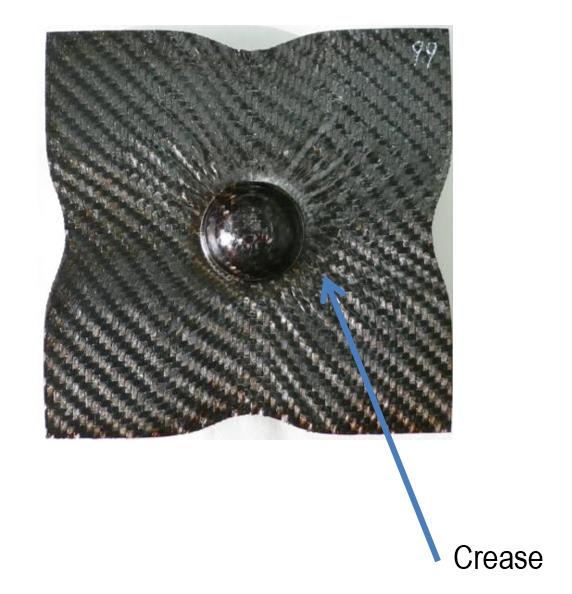

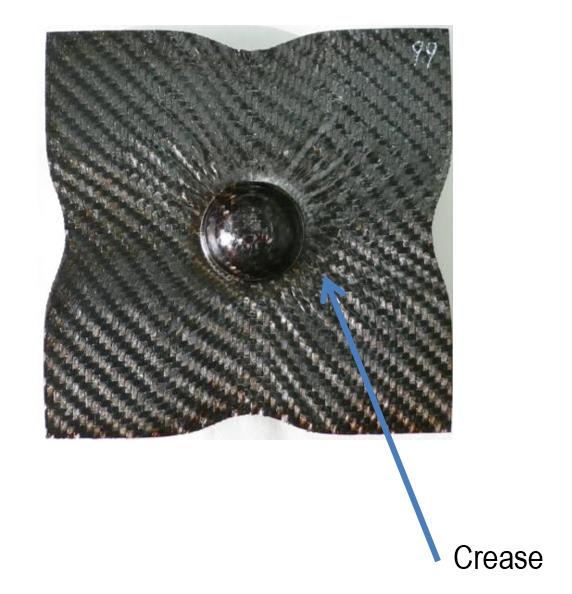

〇 3D molding sample of a CFRP laminate using carbon fiber fabric as the base

Creasing occurs during 3D molding.

Creasing occurs during 3D molding.

New Technology

〇 A CFRP laminate using carbon fiber knitted material as the base

Point: Since the base fabric has elasticity, the material is less subject to creasing during molding.

However, it is difficult to produce knitted material using carbon fiber. Carbon fiber intermediate material that can be easily knitted must be developed.

Point: Since the base fabric has elasticity, the material is less subject to creasing during molding.

However, it is difficult to produce knitted material using carbon fiber. Carbon fiber intermediate material that can be easily knitted must be developed.

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 2017/3; progress: 100%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Gifu University (role: development of fiber intermediate material)

Industrial Technology Center of the Gifu Prefectural Government (role: development of fiber intermediate material)

Private companies in Gifu Prefecture (role: development of knitted fabric producing technology)

- Example of Application

- ・Health care products

・Sports equipments

・Automobile parts, etc.

- Technical Problems

- ・Improved adhesion between carbon fiber and thermoplastic resin

・The strength of CFRP knitted fabric is inferior to CFRP fabric. It is important to consider the balance between three-dimensional formability and physical properties such as strength for right situations.

- Collaborator needed to Improve

- Company that will work on the development of a 3D molding technology for CFRP laminates using knitted material as the base in cooperation with the center

- Technical WEB page

- http://www.iri.rd.pref.gifu.lg.jp/index.php

Inquiries

- Personnel / Department

- Textile and Paper Division / Senior Research Specialist, Koji Hayashi

- Address

- 1288 Oze, Seki-shi, Gifu, 501-3265 Japan

- Contact

-

TEL:+81-575-22-0147

FAX:+81-575-24-6976

Inquiry Form

Outline of Company and Organization

- Location

- 1288 Oze, Seki-shi, Gifu, 501-3265 Japan

- Contact

-

TEL:+81-575-22-0147

FAX:+81-575-24-6976

- Capital / No. of Employees

- 0 yen / 78 employees

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.gitec.rd.pref.gifu.jp/

Update date: 2020/3/3