Ishikawa Jyushi Co., Ltd.

CFRTP molding method by resin coating technique

CFRTP molding method by resin coating technique

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ CFRTP ] [ end face processing ] [ molding ]

Point of the Proposed Technology

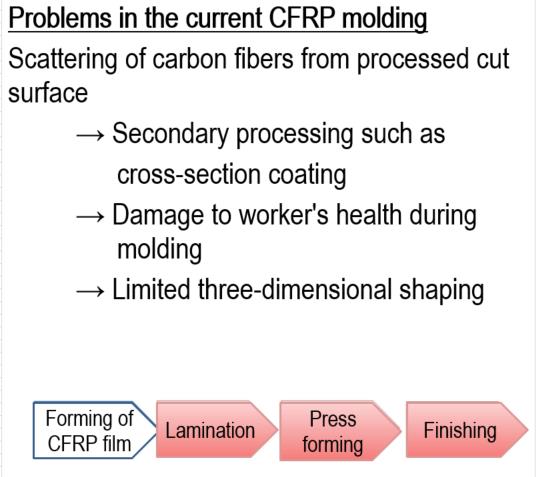

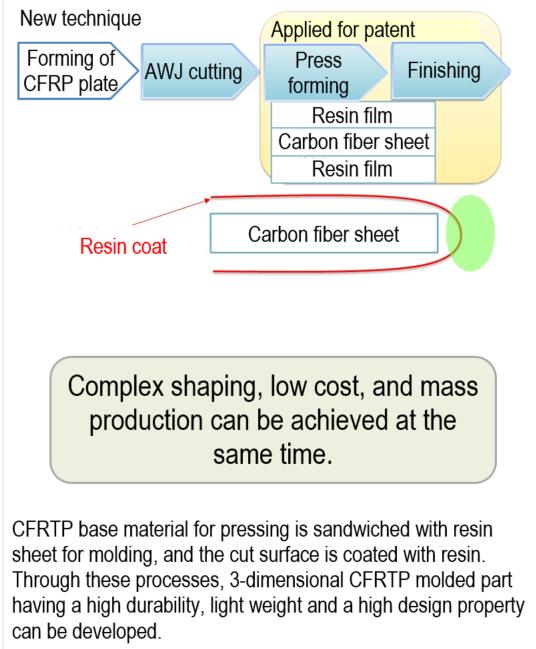

An integrated forming method by which a product is molded and at the same time, the cut surface is coated with resin is proposed. The water jet cutting method is adopted, thereby trapping carbon fiber dusts in water during cutting and preventing dusts from scattering in the cutting process. This is a revolutionary technique also in press molding into a three-dimensional shape, in which a CFRTP base material to be pressed is sandwiched with resin sheet for forming and the cut surface is coated with resin to prevent carbon fiber dusts from the cut surface from scattering.

Effect(s)

No end face processing required (secondary processing)

Cost reduction by integral molding

Cost reduction by integral molding

Conventional Technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 2017/11; progress: 40%)

- Intellectual Property Right

- Applying

- Joint Researchers (their role)

- National Institute of Technology, Ishikawa College (assessment of end surface, assessment of joint surface of CFRTP)

Industrial Research Institute of Ishikawa (assessment of physical properties of CFRTP, support for trial manufacture of resin sheet)

- Example of Application

- Artificial limb/artificial leg manufacturing field, automobile, aircraft, wheel chair, baby carriage

- Technical Problems

- The technical issues such as prevention of scattering and collection of carbon fibers during cutting process, mold structure for controlling flow of resin film for coating, control of film thickness of product end face must be solved.

- Collaborator needed to Improve

- Companies having findings about shortening and automatization of molding cycle toward mass production

Universities and research organizations having findings about joining mechanism of different kinds of materials

- Technical WEB page

- http://www.ishikawajyushi.net/facility/

Inquiries

- Personnel / Department

- / Executive Director, Tsutomu Ishikawa

- Address

- Ta1-8, Utani-machi, Kaga-city, Ishikawa, 922-0312, Japan

- Contact

-

TEL:+81-761-77-4556

FAX:+81-761-77-4629

Inquiry Form

Outline of Company and Organization

- Location

- Ta1-8, Utani-machi, Kaga-city, Ishikawa, 922-0312, Japan

- Contact

-

TEL:+81-761-77-4556

FAX:+81-761-77-4629

- Capital / No. of Employees

- 48,000,000 yen / 95 employees

- Product Line

- Industrial parts, tableware, sundry goods for home use

- Major Customers

- Daihen Fuse Corporation, Suncorona Oda Co., Ltd. Fukui Craft Co., Ltd.

- Overseas Base(s)

- None

- Certification

- ISO9001 acquired.

- Company/Organization WEB page

- http://www.ishikawajyushi.net/

Update date: 2020/2/1