Industrial Research Institute of Shizuoka Prefecture, Hamamatsu Industrial Technical Assistance Center

Optimization of cutting conditions by evaluating CFRP cutting

Optimization of cutting conditions by evaluating CFRP cutting

- Technical Classification:

- [ Processing ]

- Products:

- Keyword:

- [ cutting ] [ Cutting resistance ] [ High speed camera ] [ Optimization of cutting conditions ]

Point of the Proposed Technology

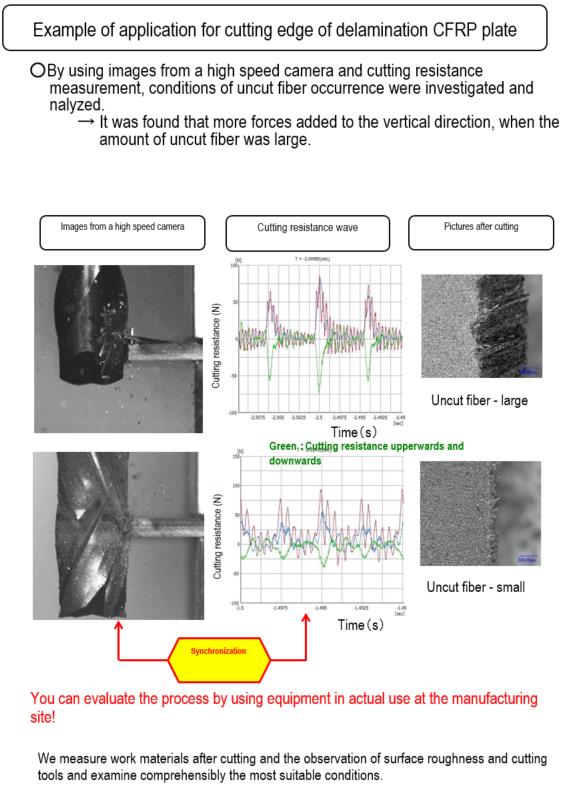

・Analyze cutting dynamics of equipment in actual use by using a high speed camera and a tool dynamometer.

・Analyze cutting surface and tools by using a roughness measuring device, three-dimensional measuring machine and a video microscope.

・Consider the most suitable cutting conditions by investigating the relevance of a various evaluation data.

・Analyze cutting surface and tools by using a roughness measuring device, three-dimensional measuring machine and a video microscope.

・Consider the most suitable cutting conditions by investigating the relevance of a various evaluation data.

Effect(s)

Optimization of CFRP cutting

Conventional Technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: no)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Not open to the public (Please inquire.)

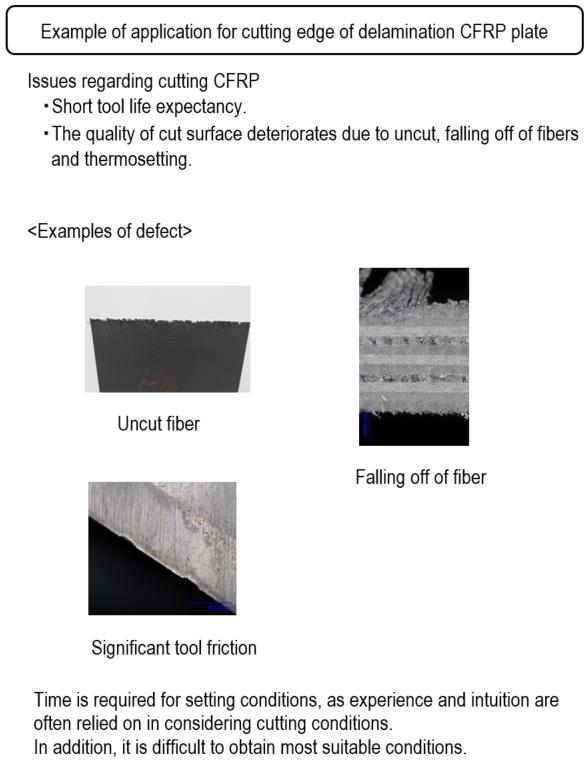

- Example of Application

- Support to optimize CFRP cutting conditions

Support for developing tools for CFRP cutting

- Technical Problems

- ・With a high speed camera, in order to observe the cutting point, it is necessary to remove the cover of the processor. A space to install a camera and a peripheral device is required. In addition, cutting process with cutting oil cannot be observed.

・In terms of a tool dynamometer, there are limitations on the size of a work piece which can be attached to the sensor. So, in some cases, evaluating with actual products may be difficult.

・The use of facility and commissioned research has been carried out mainly for companies in Shizuoka Prefecture.

- Collaborator needed to Improve

- ・Please contact to discuss the possibility of applicability of this technology seeds.

- Technical WEB page

- http://www.iri.pref.shizuoka.jp/hamamatsu/index.html

Inquiries

- Personnel / Department

- Machinery Section /

- Address

- 1-3-3, Shinmiyakoda, Kita-ku, Hamamatsu City, Shizuoka, 431-2103, Japan

- Contact

-

TEL:+81-53-428-4155

FAX:81-53-428-4160

Inquiry Form

Outline of Company and Organization

- Location

- 1-3-3, Shinmiyakoda, Kita-ku, Hamamatsu-shi, Shizuoka, 431-2103, Japan

- Contact

-

TEL:+81-53-438-4152

FAX:+81-53-428-4160

- Capital / No. of Employees

- 0 yen / 35 employees

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.iri.pref.shizuoka.jp/hamamatsu/index.html

Update date: 2020/1/23