KITAGAWA SEIKI CO., LTD.

Molding machine for CFRTP continuous fiber laminated plate

Molding machine for CFRTP continuous fiber laminated plate

- Technical Classification:

- [ Intermediate Products ] [ Molding ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ continuous fiber ] [ Press machine ] [ stampable sheet ] [ Thermoplastic ] [ UD ]

Point of the Proposed Technology

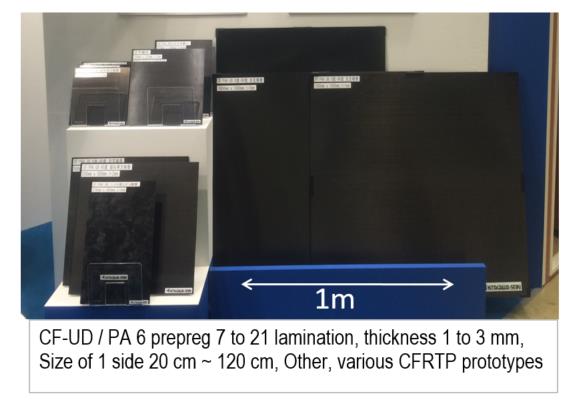

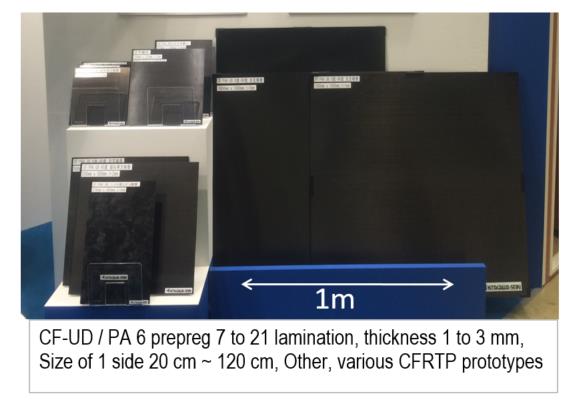

A molding method and machine for CFRTP continuous fiber laminated plate which is integrated by a continuous fiber prepreg sheet of CFRTP being laminated, and heated/pressurized by a press machine. A high quality CFRTP continuous fiber laminated plate is molded by using a vacuum flat plate press machine and a unique jig construction without using delicate molds.

Developing technology and equipment capable of mass production of high-performance CFRTP laminated plates by combining an automatic laminating machine (currently under development) capable of laminating UD prepreg tape at high speed with optional laminated configurations (angles/number of plates), and a large/multi-stage press machine.

Developing technology and equipment capable of mass production of high-performance CFRTP laminated plates by combining an automatic laminating machine (currently under development) capable of laminating UD prepreg tape at high speed with optional laminated configurations (angles/number of plates), and a large/multi-stage press machine.

Effect(s)

Cost reduction

Applicable to large size

Applicable to large size

Conventional Technology

In molding a laminated sheet with a prescribed thickness by laminating CFRTP continuous fiber prepreg sheets, heating and pressurization are generally performed in order to mold a good quality laminate with a small void ratio. The conventional technologies have the following problems.

・ Autoclaving

The running cost is high, and secondary consumable material is required.

・ Metal mold + press machine

An elaborate metal mold is required. The large-size metal mold is especially expensive and very heavy in weight as well.

In addition, resin leakage from the mold may occur during heating or pressurization.

In addition, automatic laminating machines for prepreg tapes are not suitable for mass production because it takes too much time to laminate one plate with a device capable of laminating UD tape with high degree of flexibility.

・ Autoclaving

The running cost is high, and secondary consumable material is required.

・ Metal mold + press machine

An elaborate metal mold is required. The large-size metal mold is especially expensive and very heavy in weight as well.

In addition, resin leakage from the mold may occur during heating or pressurization.

In addition, automatic laminating machines for prepreg tapes are not suitable for mass production because it takes too much time to laminate one plate with a device capable of laminating UD tape with high degree of flexibility.

New Technology

Since the work can be heated and pressed while maintaining its shape with a simple tool configuration (patent pending) and a flat hot plate press machine which the company has developed without using an elaborate metal mold, a good quality CFRTP laminate with a small void ratio can be molded at low cost.

Since the tool configuration is simple, the whole system can be flexible in size- and shape-changes. In addition, the time and effort required for cleaning and maintenance can be substantially reduced in comparison with metal molds.

The void ratio can be reduced and oxidization deterioration of the resin can be controlled through laminating under vacuum (reduced ressure).

Developing technology and equipment capable of mass production of high-performance CFRTP laminated plates by combining an automatic laminating machine (currently under development) capable of laminating UD prepreg tape at high speed with optional laminated configurations (angles/number of plates), and a large/multi-stage press machine using described-above press molding technology.

Since the tool configuration is simple, the whole system can be flexible in size- and shape-changes. In addition, the time and effort required for cleaning and maintenance can be substantially reduced in comparison with metal molds.

The void ratio can be reduced and oxidization deterioration of the resin can be controlled through laminating under vacuum (reduced ressure).

Developing technology and equipment capable of mass production of high-performance CFRTP laminated plates by combining an automatic laminating machine (currently under development) capable of laminating UD prepreg tape at high speed with optional laminated configurations (angles/number of plates), and a large/multi-stage press machine using described-above press molding technology.

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 2020/3; progress: 80%)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Hiroshima Prefectural Technology Research Institute (West Region Industrial Research Center)

- Example of Application

- Automobile parts, etc., lightweight members

- Technical Problems

- Availability of CFRTP prepreg sheets is poorCFRTP

- Collaborator needed to Improve

- Fiber/Resin material manufacturers

Material manufacturers that consider producing stampable sheets

Automobile manufacturers and automobile parts manufacturers

- Technical WEB page

- http://www.kitagawaseiki.co.jp

Inquiries

- Personnel / Department

- Market Research Section / Manager, Hiroyuki Takei

- Address

- 800-8, Ukai-cho, Fuchu-shi, Hiroshima, 726-0002, Japan

- Contact

-

TEL:+81-847-40-1200(代表)

FAX:+81-847-40-1202

Inquiry Form

Outline of Company and Organization

- Location

- 800-8, Ukai-cho, Fuchu-shi, Hiroshima, 726-0002, Japan

- Contact

-

TEL:+81-847-40-1200

FAX:+81-847-40-1202

- Capital / No. of Employees

- 1,335,010,000 yen / 120 employees

- Product Line

- Hydraulic press machines, transfer machines, and other machinery and equipment

- Major Customers

- Printed board related manufacturers, automobile parts manufacturers

- Overseas Base(s)

- Shanghai

- Certification

- ISO14001

- Company/Organization WEB page

- http://www.kitagawaseiki.co.jp

Update date: 2020/2/12