SUGINO MACHINE LIMITED

Pneumatic drilling unit for composite materials such as CFRP

Pneumatic drilling unit for composite materials such as CFRP

- Technical Classification:

- [ Processing ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ Air Driven ] [ CFRP ] [ composite materials ] [ Delamination prevention ] [ drilling ] [ Pneumatic ]

Point of the Proposed Technology

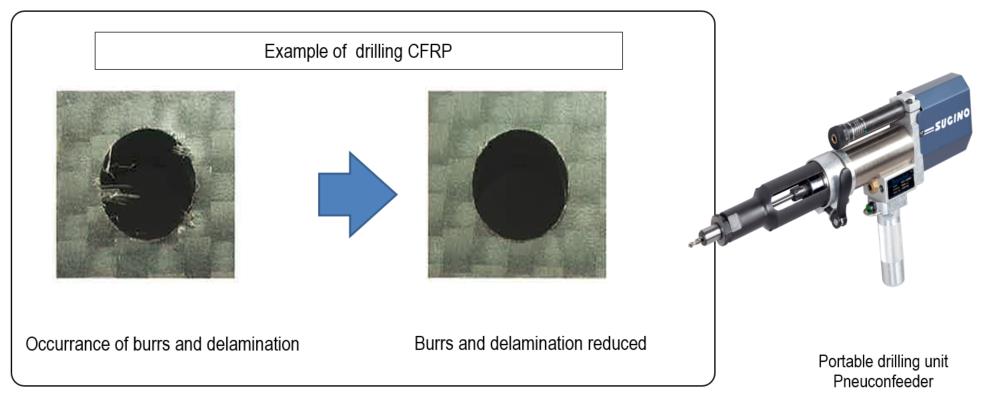

・Light-weight and compact portable drilling unit "Pneuconfeeder", utilizing Sugino Machine's drilling technology.

・Built-in high torque and high durable air motor.

・Stable drilling due to high precision spindle structure.

・Built-in high torque and high durable air motor.

・Stable drilling due to high precision spindle structure.

Effect(s)

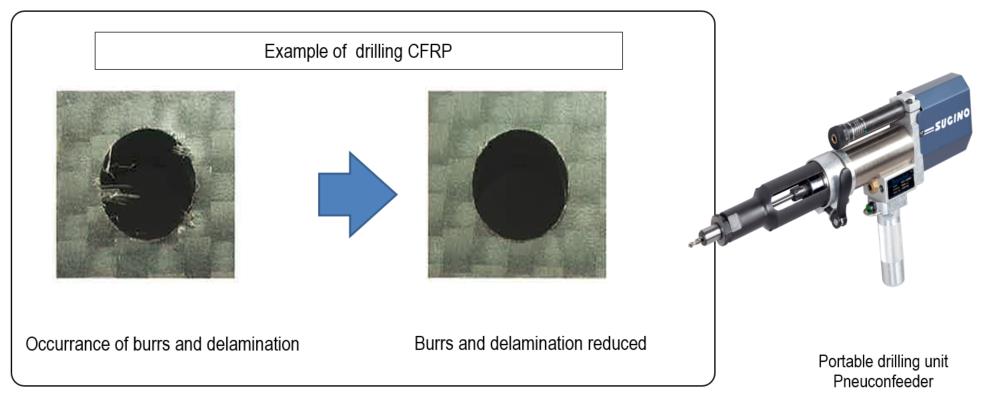

・Burrs and delamination reduced in drilling CFRP

・Weight reduction of the drilling unit

・Weight reduction of the drilling unit

Conventional Technology

Example of application to CFRP

・With conventional portable drilling unit, spindle precision was not enough. Therefore, when drilling CFRP, there were problems like burrs and delamination, and also shortening of tool life.

・With the structure of conventional portable drilling unit, it was not able to set drilling conditions suitable for different materials.

As a result, laminated workpieces with different types of materials took longer time with poor efficiency.

・With conventional portable drilling unit, spindle precision was not enough. Therefore, when drilling CFRP, there were problems like burrs and delamination, and also shortening of tool life.

・With the structure of conventional portable drilling unit, it was not able to set drilling conditions suitable for different materials.

As a result, laminated workpieces with different types of materials took longer time with poor efficiency.

New Technology

Example of application to CFRP

・With high precision spindle structure, high level run-out control is achieved. It can reduce burrs and delamination, and prolong tool life.

・Pneuconfeeder is a complete air driven unit equipped with air motor for spindle rotation and air cylinder for feeding forward and backward. Air driven unit can process the work in accordance with work load, thus enables efficient drilling even in case of composite material laminated with different types of materials .

・With two-step feed speed ragulator equipped, it is possible to set pre-exit low feed which can reduce burrs and delamination.

・With high precision spindle structure, high level run-out control is achieved. It can reduce burrs and delamination, and prolong tool life.

・Pneuconfeeder is a complete air driven unit equipped with air motor for spindle rotation and air cylinder for feeding forward and backward. Air driven unit can process the work in accordance with work load, thus enables efficient drilling even in case of composite material laminated with different types of materials .

・With two-step feed speed ragulator equipped, it is possible to set pre-exit low feed which can reduce burrs and delamination.

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Example of Application

- ・Driling of CFRP

・Drilling for the industries such as aerospace, shipbuilding, automobile and construction

- Technical Problems

- ・ We offer technical proposal, design and manufacturing depending on the requests of customers.

- Collaborator needed to Improve

- ・Customers who employs various drilling with portable drilling unit.

- Technical WEB page

- http://www.sugino.com/site/aviation-drilling-unit/

Inquiries

- Personnel / Department

- Precision Machine Division / Ryuhei Yagou

- Address

- 1800, Nakanoshima, Namerikawa-shi, Toyama, 936-8588, Japan

- Contact

-

TEL:+81-76-475-5111

FAX:+81-76-486-0016

Inquiry Form

Outline of Company and Organization

- Location

- 2410 Hongo, Uozu-shi, Toyama, 937-8511 Japan

- Contact

-

TEL:+81-765-24-5111

FAX:+81-765-24-5051

- Capital / No. of Employees

- 2,324,670,000 yen / 1630 employees(Whole group)

- Product Line

- Ultra-high pressure water cutting device, wet/dry atomizing unit, drilling unit, etc.

- Major Customers

- Overseas Base(s)

- USA, Mexico, France, Germany, China, Thailand, Singapore, Indonesia, etc.

- Certification

- Company/Organization WEB page

- http://www.sugino.com/index-e.html

Update date: 2020/2/2