Ichimura Sangyo Co., Ltd.

Development of thermoplastic CFRP sheets and development of their applications

Development of thermoplastic CFRP sheets and development of their applications

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ stampable molding ] [ Thermoplastic CFRP ]

Point of the Proposed Technology

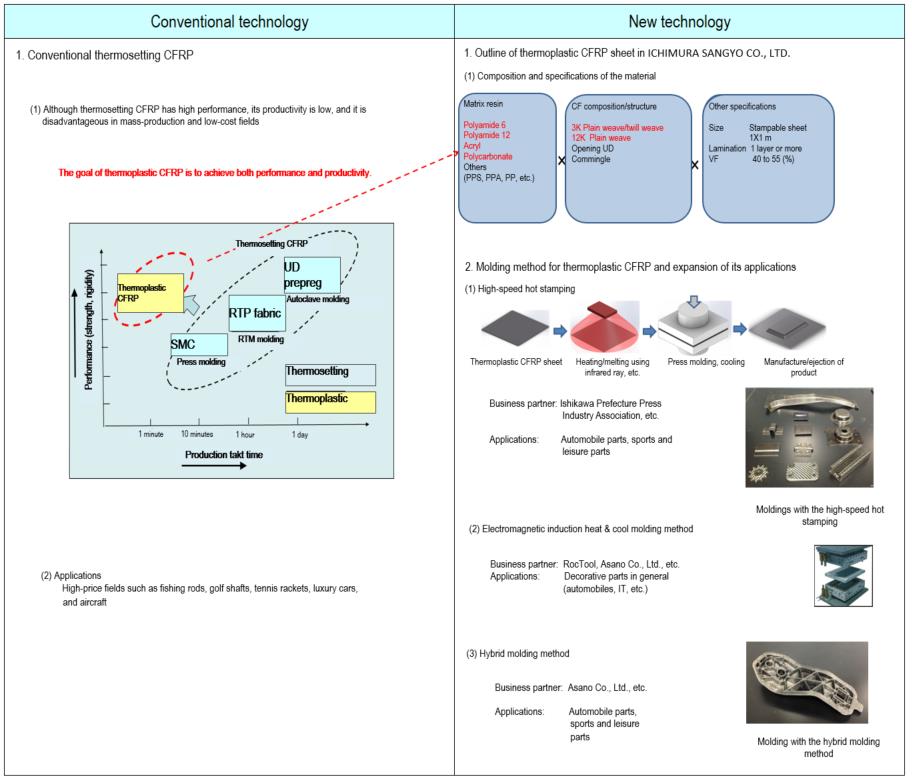

・ A carbon fiber reinforced sheet can be molded at a short takt time of 30 seconds to 5 minutes

(10 minutes to 24 hours with conventional thermosetting CFRP)

・ Proposing the thermoplastic resin optimal for the product requirements, and supplying it for testing

(high strength/high impact: PA6; high heat resistance: PPS, design/appearance: PMMA, PC, etc.)

(10 minutes to 24 hours with conventional thermosetting CFRP)

・ Proposing the thermoplastic resin optimal for the product requirements, and supplying it for testing

(high strength/high impact: PA6; high heat resistance: PPS, design/appearance: PMMA, PC, etc.)

Effect(s)

■ Productivity improvement (compared with metal/thermosetting)

■ Cost reduction (compared with metal/thermosetting)

■ Weight reduction (compared with metal)

■ Cost reduction (compared with metal/thermosetting)

■ Weight reduction (compared with metal)

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- 1. Toray Industries Inc.: human support, technical support, customer referral, etc.

2. Kanazawa Institute of Technology, Industrial Research Institute of Ishikawa:

performance test, etc.

3. Molding manufacturers: development of thermoplastic CFRP molding method

(Ishikawa Prefecture Press Industry Association, in particular)

4. Equipment manufacturers: linkage with thermoplastic CFRP molding equipment

- Example of Application

- ・ Parts for sports and leisure (under development)

・ Automobile parts (under development)

- Technical Problems

- ・ Technical task: Achieving high strength and high rigidity by improving resin impregnation into carbon fiber without increasing the material cost and manufacturing cost

・ Constraints and conditions: All material formulas and manufacturing methods must be kept confidential (ICHIMURA SANGYO CO., LTD.’s technology)

・ Business plan: Already started supply for testing to domestic companies, universities and research institutes for fee. Aims at conversion from demand for test use to commercialization.

- Collaborator needed to Improve

- ・ Molding manufacturers, equipment manufacturers, end users, universities and research institutes

- Technical WEB page

- https://www.ichimura.co.jp/products/pro_003.html

Inquiries

- Personnel / Department

- Advanced Material Development & Manufacturing Dept. / Director General Manager, Hirotaka Kawamura

- Address

- 5-20 Minamicho, Kanazawa City, Ishikawa Pref. 920-8633, Japan

- Contact

-

TEL:+81-76-263-1177

Inquiry Form

Outline of Company and Organization

- Location

- 530-6118 18F Nakanoshimma Bldg. 3-3-23, Nakanoshima, Kita-ku, Osaka-City, Osaka 530-6118, Japan

- Contact

-

TEL:+81-6-7223-8300

- Capital / No. of Employees

- 1,000,000,000 yen / 128 employees

- Product Line

- Synthetic fabric, carbon fiber related materials, EPS moldings

- Major Customers

- TORAY, Sekisui Plastics Co., Ltd., Komatsu Seiren

- Overseas Base(s)

- Shanghai

- Certification

- ISO14001

- Company/Organization WEB page

- https://www.ichimura.co.jp/

Update date: 2020/1/31