Industrial Research Institute of Ishikawa

Drilling technique for carbon fiber reinforced thermoplastic (CFRTP)

Drilling technique for carbon fiber reinforced thermoplastic (CFRTP)

- Technical Classification:

- [ Processing ]

- Products:

- [ Service ]

- Keyword:

- [ Carbon fiber reinforced thermoplastic ] [ CFRTP ] [ drilling ] [ Step drill ]

Point of the Proposed Technology

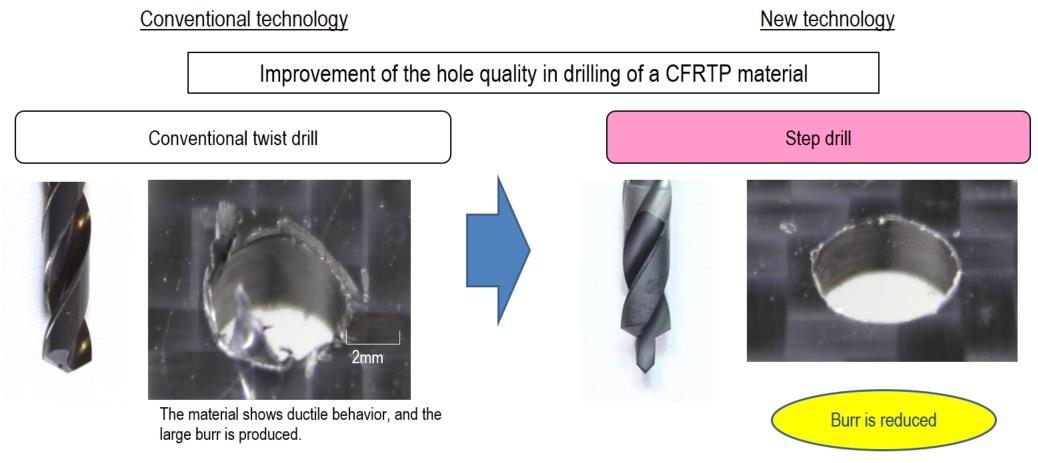

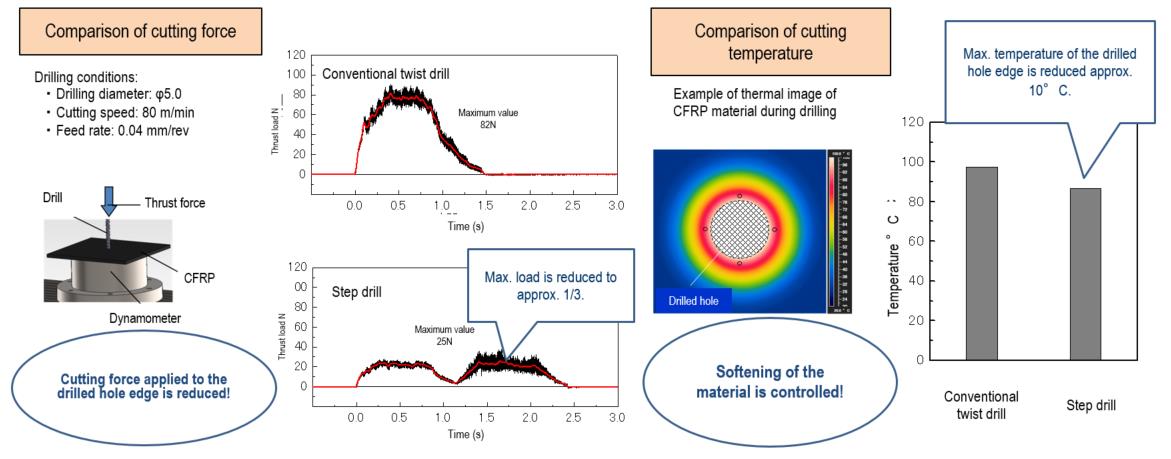

CFRTP materials shows ductile behavior in a drilling process in contrast with CFRP with thermosetting resin, and it causes a problem of large burr remaining at the drilled hole end using a conventional twist drill. In order to prevent large burr growing, we have proposed “a step drill” that distributes the cutting force for the work plate in drilling.

Effect(s)

Improvement of the drilled hole quality of a CFRTP material (burr reduction)

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 2014/3; progress: 100%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Example of Application

- Drilling process of CFRTP molding parts

- Technical Problems

- Evaluation of the tool life, and extension of tool life

- Collaborator needed to Improve

- Cutting tool manufacturer

- Technical WEB page

- http://www.irii.jp/jisedai/index.html

Inquiries

- Personnel / Department

- Machinery/Metal Department / Researcher, Kenichi Hirosaki

- Address

- 2-1, Kuratsuki, Kanazawa, Ishikawa Prefecture, 920-8203, Japan

- Contact

-

TEL:+81-76-267-8089

Inquiry Form

Outline of Company and Organization

- Location

- 2-1, Kuratsuki, Kanazawa, Ishikawa Prefecture, 920-8203, Japan

- Contact

-

TEL:+81-76-267-8081

- Capital / No. of Employees

- 0 yen /

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.irii.jp

Update date: 2020/1/23