NORITAKE CO., LIMITED

Grinding tool "Grit Ace" (Change from cutting to grinding to realize high-quality with high-efficiency processing, and reduce the cost)

Grinding tool "Grit Ace" (Change from cutting to grinding to realize high-quality with high-efficiency processing, and reduce the cost)

- Technical Classification:

- [ Processing ]

- Products:

- [ Jig ]

- Keyword:

- [ cutting ] [ drilling ] [ grinding ] [ Hole processing ]

Point of the Proposed Technology

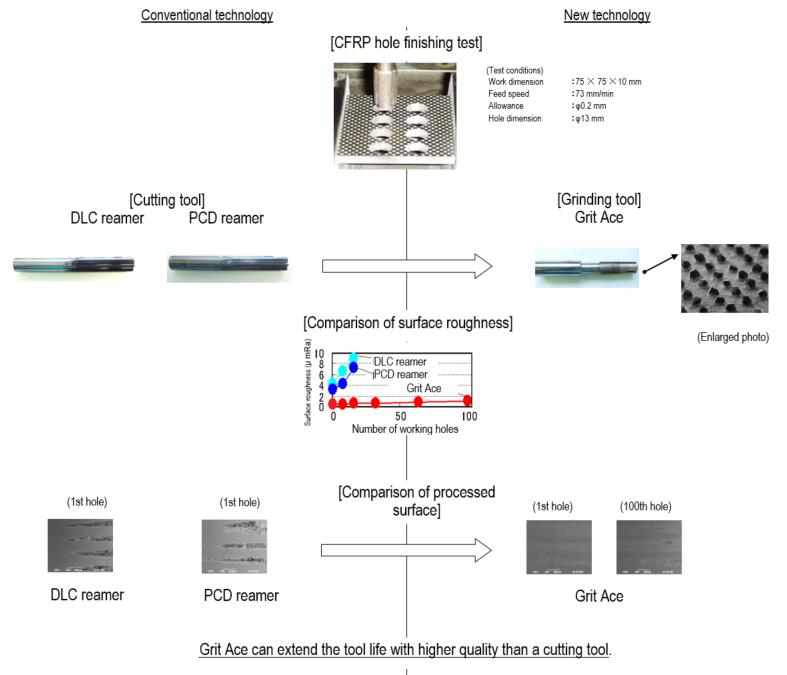

- Quality of processed surface will be improved by processing with abrasive grains (diamond) as the cutting blade which are smaller than a cutting tool.

- Uniform array of abrasive grains and the strongly sustained structure with the projected height will realize the high-efficiency processing.

- Uniform array of abrasive grains and the strongly sustained structure with the projected height will realize the high-efficiency processing.

Effect(s)

- Shortening of the processing time

- Improvement of the quality of the processed surface

- Reduction of the processing cost

- Extension of the tool life

- Improvement of the quality of the processed surface

- Reduction of the processing cost

- Extension of the tool life

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Example of Application

- - Drilling on the airframe (CFRP) of aircraft

- High-efficiency processing of automotive parts (metal)

- Technical Problems

- - Grit Ace can maximize the tool performance when it is used at a higher rotation frequency than a cutting tool.

- Collaborator needed to Improve

- - Cooperation with manufacturers that produce aircraft, automobiles, etc. for application development

- Technical WEB page

- https://www.noritake.co.jp/products/support/detail/4/

Inquiries

- Personnel / Department

- Daiya Group, INDUSTRIAL PRODUCTS GROUP SALES DEPARTMENT / Group Leader, Akio Sataka

- Address

- 3-1-36, NORITAKE-SHINMACHI, NISHI-KU, NAGOYA, 451-8501, JAPAN

- Contact

-

TEL:+81-52-561-9807

FAX:+81-52-561-9759

Inquiry Form

Outline of Company and Organization

- Location

- 3-1-36, Noritake-Shinmachi, Nishi-Ku, Nagoya 451-8501 Japan

- Contact

-

TEL:052-561-7111

- Capital / No. of Employees

- 15,632,000,000 yen / 5091 employees

- Product Line

- Grinding tools, ceramic parts, heating systems, tableware

- Major Customers

- Automobile, chemical, and electric appliance manufacturers

- Overseas Base(s)

- China, USA, etc.

- Certification

- ISO14001、ISO9001

- Company/Organization WEB page

- http://www.noritake.co.jp/

Update date: 2020/2/2