BEAMSENSE Co., Ltd.

High-accuracy analysis of resin structure by high-definition X-ray fluoroscopy by new nano-focus X-ray photography method

- Technical Classification:

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ 3D-CT ] [ fiber orientation ] [ Nondestructive testing technique ]

Point of the Proposed Technology

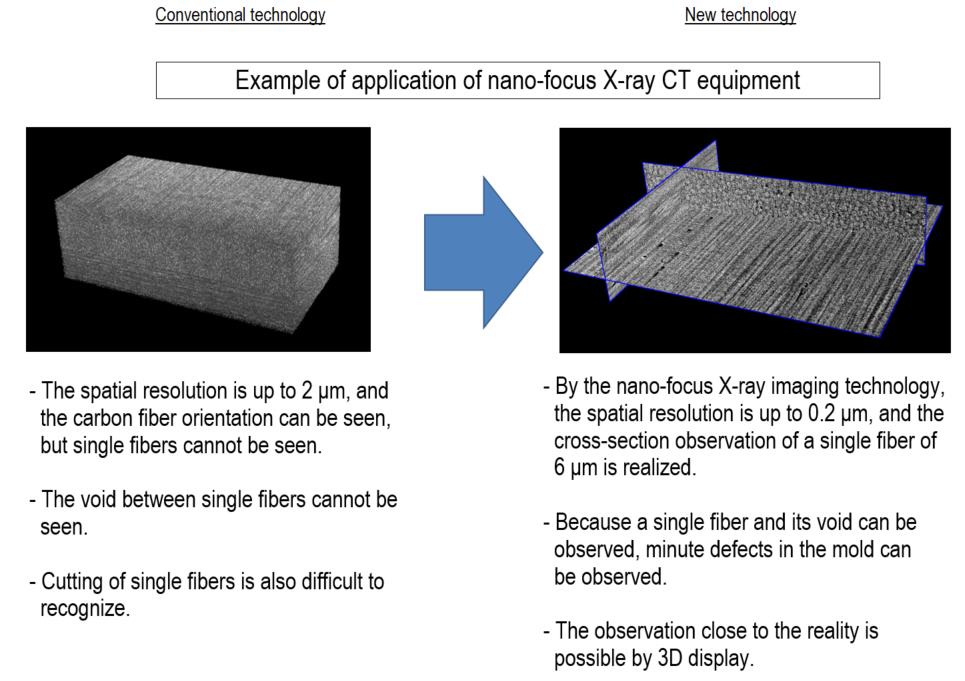

- The internal structure inspection function will be improved greatly by the small nano-focus X-ray CT equipment in place of the conventional electron microscopy.

- Because the cutting, machining, polishing, and vapor deposition processes are not necessary, the environmental load and the burden of the operator will be reduced greatly.

- By nano-focus X-ray tomography (CT), not only the surface but also the inside nano level 3D structure can be observed and analyzed.

- Because the cutting, machining, polishing, and vapor deposition processes are not necessary, the environmental load and the burden of the operator will be reduced greatly.

- By nano-focus X-ray tomography (CT), not only the surface but also the inside nano level 3D structure can be observed and analyzed.

Effect(s)

Equipment cost: Reduction of about 50% compared to conventional method

Spatial resolution: 0.2 μm by maximum magnification

Equipment installation area: 1/4 compared to conventional method

Spatial resolution: 0.2 μm by maximum magnification

Equipment installation area: 1/4 compared to conventional method

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: no)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- National Institute of Advanced Industrial Science and Technology (Role: Reconfiguration of 3D image from stereo X-ray image)

Kyoto Institute of Technology (Role: Research, development, and evaluation on 3D X-ray CT software)

Iwate Prefectural University (Role: Measurement of 3D CT image, and research on information processing technology)

- Example of Application

- - Inspection of resin parts of automobiles

- Inspection of small parts of various electronic equipment

- Technical Problems

- - Because the nano-focus X-ray generator is expensive, the system will be expensive. If the cost is improved, the adoption to plants will be expanded.

- Because the X-ray output of the nano-focus X-ray generator is weak, the photography takes time. The sensitivity of the X-ray CCD should be improved to shorten the photographing time.

- The validation service at our company will be promoted continuously until the nano-focus X-ray generator is improved.

- Collaborator needed to Improve

- - 3D-CAD related companies with knowledge of 3DCT image processing technology

- Research institutes such as universities, etc. with 3DCT evaluation technology and equipment

- Technical WEB page

- https://beamsense.co.jp/?page_id=2

Inquiries

- Personnel / Department

- / President, Sueki Baba

- Address

- 2-19-16, Izumi-cho, Suita-City, Osaka, 564-0041, Japan

- Contact

-

TEL:+81-6-6384-9563

Inquiry Form

Outline of Company and Organization

- Location

- 2-19-16, Izumi-cho, Suita-City, Osaka, 564-0041, Japan

- Contact

-

TEL:+81-6-6384-9563

- Capital / No. of Employees

- 10,000,000 yen / 5 employees

- Product Line

- Industrial X-ray fluoroscope

- Major Customers

- Panasonic Corporation

- Overseas Base(s)

- Agents in China, Taiwan, Thailand, and Malaysia

- Certification

- None

- Company/Organization WEB page

- http://beamsense.co.jp/

Update date: 2020/3/6