MARUHACHI Corp.

2D & 3D Pre-form Materials (thermoplastic materials, thermoset materials)

2D & 3D Pre-form Materials (thermoplastic materials, thermoset materials)

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ] [ Service ]

- Keyword:

- [ advanced composite materials ] [ AFP ] [ ATL ] [ broad width ] [ high rigidity ] [ high strength ] [ lightweight ] [ partial reinforcement ] [ pre-preg sheets ] [ Thermoplastic resin ] [ thermoset resin ] [ thin layer ]

Point of the Proposed Technology

Pre-form Materials

2D: laminated sheet materials, tailored stacking materials (arbitrarily oriented tape laminated material)

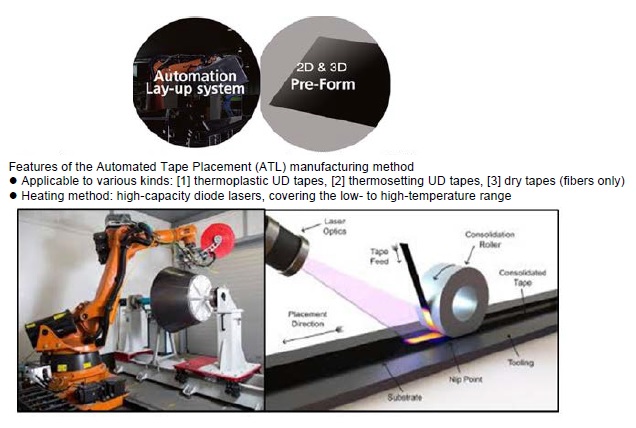

3D: Three-dimensional forming products, ATL (tape lay-up) lamination products

They can be used in built-in into and assembly in the final forming process as composite intermediate parts.

2D: laminated sheet materials, tailored stacking materials (arbitrarily oriented tape laminated material)

3D: Three-dimensional forming products, ATL (tape lay-up) lamination products

They can be used in built-in into and assembly in the final forming process as composite intermediate parts.

Effect(s)

・ A wide variety of plastics materials can be used (PP. PA, PC, TPU, PPS, LCP, PEEK, PEKK、etc.).

・ It is possible to be used for making into products in combination with existing technologies such as mold injection.

・ It is possible to study response to a future environment as materials with recyclability.

・ It is possible to make additional processing such as partial reinforcement.

・ Delivery will be made as PF products in the minimum necessary size making it possible to contribute to reduction of material loss.

・ It is possible to be used for making into products in combination with existing technologies such as mold injection.

・ It is possible to study response to a future environment as materials with recyclability.

・ It is possible to make additional processing such as partial reinforcement.

・ Delivery will be made as PF products in the minimum necessary size making it possible to contribute to reduction of material loss.

New Technology

2D Pre-form Materials

MaterialsRaw materials in use: Carbon fibers, glass fibers, aramid fibers, and other high-strength fibers.

Targets are UD-Tapes, Organic sheets, Random sheets, etc. that use the above materials.

Laminated constitution: It is possible to realize an arbitrary structure with the orientation layer of 0, 90, 45, or -45 degrees based on a QI/pseudo-isotropiclamination.

It is also possible to use cloth materials, random materials, and core materials (foam materials, honeycomb materials, etc.).

Size: w 500 mm × L 500 mm @ medium/high temperature types

w 195 mm × L 1,150 mm @ medium temperature type

w 300 mm × L 1,500 mm @ high temperature type

Thickness: 1.0 mm to 5.0 mm

MaterialsRaw materials in use: Carbon fibers, glass fibers, aramid fibers, and other high-strength fibers.

Targets are UD-Tapes, Organic sheets, Random sheets, etc. that use the above materials.

Laminated constitution: It is possible to realize an arbitrary structure with the orientation layer of 0, 90, 45, or -45 degrees based on a QI/pseudo-isotropiclamination.

It is also possible to use cloth materials, random materials, and core materials (foam materials, honeycomb materials, etc.).

Size: w 500 mm × L 500 mm @ medium/high temperature types

w 195 mm × L 1,150 mm @ medium temperature type

w 300 mm × L 1,500 mm @ high temperature type

Thickness: 1.0 mm to 5.0 mm

3D Pre-form Materials

Raw materials in use: Carbon fibers, glass fibers, aramid fibers, and other high-strength fibers.

Targets are UD-Tapes, Organic sheets, Random sheets, etc. that use the above materials.

Laminated constitution: It is possible to apply an arbitrary reinforcing material arrangement or lamination structure at orientation angles other than 0, 90, 45, and -45 degrees.

It is also possible to use cloth materials, random materials, and core materials (foam materials, honeycomb materials, etc.).

Size: Lamination constituent materials in the range of W 1,000 mm × L 1,000 mm.

Pipe materials, containers, etc. in the range of W 500 mm × L 2,000 mm × H 500 mm.

* Medium/High temperature types

Raw materials in use: Carbon fibers, glass fibers, aramid fibers, and other high-strength fibers.

Targets are UD-Tapes, Organic sheets, Random sheets, etc. that use the above materials.

Laminated constitution: It is possible to apply an arbitrary reinforcing material arrangement or lamination structure at orientation angles other than 0, 90, 45, and -45 degrees.

It is also possible to use cloth materials, random materials, and core materials (foam materials, honeycomb materials, etc.).

Size: Lamination constituent materials in the range of W 1,000 mm × L 1,000 mm.

Pipe materials, containers, etc. in the range of W 500 mm × L 2,000 mm × H 500 mm.

* Medium/High temperature types

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 2020/5; progress: 0%)

- Intellectual Property Right

- Applying

- Joint Researchers (their role)

- Osaka University (role: simulation to analyze damage growth in advanced composite materials)

Kyoto Institute of Technology (role: evaluation technology of advanced composite materials)

University of Tokyo (role: technology, analysis and evaluation on composite materials)

Nihon University (role: technology, analysis and evaluation on composite materials)

Doshisha University (role: technological support and evaluation on composite materials)

ICC/Kanazawa Institute of Technology (role: support in commercialization and mass production)

Industrial Technology Center of Fukui Prefecture (role: fiber opening technology)

- Example of Application

- Usage and destinations are not disclosed.

- Technical Problems

- Collaborator needed to Improve

- Technical WEB page

- http://www.maruhati.co.jp

Inquiries

- Personnel / Department

- / Ph,D / President & CEO, Toshi Sugahara

- Address

- 12-1 Gennyo, Maruoka, Sakai-shi, Fukui, 910-0276 Japan

- Contact

-

TEL:+81-776-67-0808

FAX:+81-776-67-8485

Inquiry Form

Outline of Company and Organization

- Location

- 12-1 Gennyo, Maruoka, Sakai-shi, Fukui, 910-0276 Japan

- Contact

-

TEL:+81-776-67-0808

FAX:+81-776-67-8485

- Capital / No. of Employees

- 80,000,000 yen / 22 employees

- Product Line

- Fiber reinforced composite material / Base material (cloth material / knit material) Prepreg material (UD material / cloth material: thermosetting type / thermoplastic type) Preform material (2D: laminated board material / tailored stack, 3D: 3D formed product ・ ATL (tape lay-up) laminated product / partially reinforced product) FW molded product (CFRP high pressure container, high pressure pipe, etc., commissioned evaluation test (high pressure burst test, cycle test, etc.)

- Major Customers

- Related companies in the field of sports goods, automobiles, aviation, machinery, energy and mass transport equipment, CFRP molding companies, trading companies and sales companies, etc.

- Overseas Base(s)

- None

- Certification

- Company/Organization WEB page

- http://www.maruhati.co.jp/en/index.html

Update date: 2020/2/15