SANKO GOSEI LTD.

Carbon fiber molding technology, metal die manufacture

Carbon fiber molding technology, metal die manufacture

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ carbon fiber ] [ Metal die ] [ molding ] [ Thermoplastic ] [ thermosetting ]

Point of the Proposed Technology

・ With use of carbon fiber instead of the conventional sheet metal, the strength is substantially increased and the weight can be reduced.

・ Since thermoplastic carbon fiber material is used, the molding time is short.

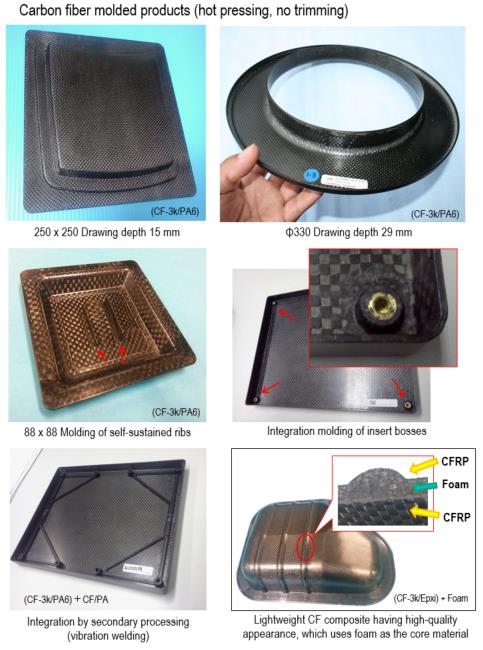

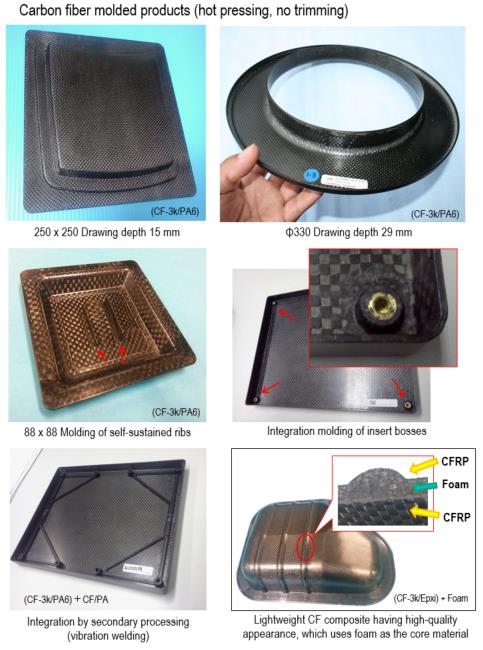

・ Since trimming of the periphery is unnecessary, a finishing process for the product is unnecessary.

・ Since it is unnecessary to make holes for securing the molding, the product strength is not lowered.

・ Since thermoplastic carbon fiber material is used, the molding time is short.

・ Since trimming of the periphery is unnecessary, a finishing process for the product is unnecessary.

・ Since it is unnecessary to make holes for securing the molding, the product strength is not lowered.

Effect(s)

・ Molding time: 30 min. ⇒ 5 min.

・ Cost: reduced by 30%

・ Trimming: unnecessary

・ Cost: reduced by 30%

・ Trimming: unnecessary

Conventional Technology

○ In the vehicle's structure, body, etc., steel sheets are used, and parts are fixed by spot welding or with bolts and welded nuts.

○ When manufacturing a vehicle structure with carbon fiber, it was difficult to draw prepreg as opposed to sheet-metal press forming because prepreg is hard to be drawn.

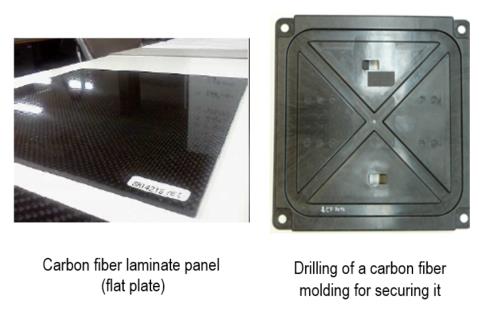

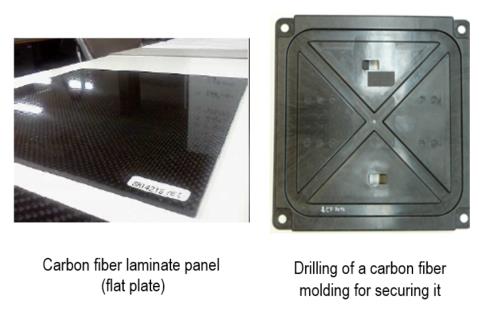

○ Since carbon fibers cannot be welded, these parts were generally drilled and secured with screws. As a result, carbon fibers were cut, causing the strength to be lowered.

○ Thick-walled molded product of carbon fiber is difficult to laminate, and its material cost is high. Sandwich panel having a core made with AL honeycomb or the like is available, but there are many problems with the application to 3D molded product.

○ When manufacturing a vehicle structure with carbon fiber, it was difficult to draw prepreg as opposed to sheet-metal press forming because prepreg is hard to be drawn.

○ Since carbon fibers cannot be welded, these parts were generally drilled and secured with screws. As a result, carbon fibers were cut, causing the strength to be lowered.

○ Thick-walled molded product of carbon fiber is difficult to laminate, and its material cost is high. Sandwich panel having a core made with AL honeycomb or the like is available, but there are many problems with the application to 3D molded product.

New Technology

Concerning the molding method in which multiple single-layer prepreg sheets are laminated and hot-press molded, we worked on the development of a molding technique which provides a guarantee of strength by die molding and reduces the forming time.

We developed a lightweight CF composite having high-quality appearance, which uses a bead foam as the core material, with single-layer prepreg sheets laminated.

We developed a lightweight CF composite having high-quality appearance, which uses a bead foam as the core material, with single-layer prepreg sheets laminated.

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 0/0; progress: 0%)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Example of Application

- ・Automobile goods

・Office automation equipment

- Technical Problems

- ・Increase in precision and reduction of time of the preforming process of thermoplastic carbon fiber substrate

・Reduction of the number of man-hours for lamination of thermosetting carbon fiber substrate

・High-speed and uniform temperature control technology in the mold heating/cooling process of hot-press molding

- Collaborator needed to Improve

- ・Company or research organization which can develop design support programs for lamination and strength of prepreg according to product shape

・Company or research organization which can develop devices for cutting, lamination and transfer of prepreg

・Company or research organization which can develop devices for controlling the heating/cooling temperature of material and mold

・Company or research institute that can develop intermediate material for efficiently producing carbon fiber parts.

- Technical WEB page

- http://www.sankogosei.co.jp/tec/jtechnology.html

Inquiries

- Personnel / Department

- Products Applied Technology, Futuristic Technology Department / Tsutomu Konishi

- Address

- 4185 Koreyasu, Nanto-shi, Toyama-ken, 939-1852, Japan

- Contact

-

TEL:+81-763-62-3899

FAX:+81-763-62-8000

Inquiry Form

Outline of Company and Organization

- Location

- 1200 Habushin, Nanto-shi, Toyama-ken, 939-1698,Japan

- Contact

-

TEL:+81-763-52-1000

FAX:+81-763-52-1925

- Capital / No. of Employees

- 4,008,000,000 yen / 603 employees

- Product Line

- Exterior and functional parts for automobiles, office automation equipment

- Major Customers

- Daihatsu Motor Co., Ltd., Honda Motor Co., Ltd., XEROX, Canon

- Overseas Base(s)

- China, Thailand, Malaysia, Philippines, India, Indonesia, UK, Hungary, Mexico

- Certification

- ISO 9001: 2008 ISO14001: 2004

- Company/Organization WEB page

- http://www.sankogosei.co.jp

Update date: 2020/2/20