TANAKA GIKEN CO., LTD.

Simple automation of winding process in forming of deformed CFRP pipe

Simple automation of winding process in forming of deformed CFRP pipe

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ cost reduction ] [ Labor saving ]

Point of the Proposed Technology

・Owing to the application of sheet winding process, fibers can be laminated at a desired angle of 0°, 90° or 45°,resulting in the substantial increase in productivity and strength.

Effect(s)

Shortening of forming time: 20%

Cost reduction: 20%

Cost reduction: 20%

Conventional Technology

(i) Manual winding process

Mass production is difficult and unevenness in quality occurred.

(ii) In the filament winding method, carbon fibers are reciprocated at 45º. Therefore, it is difficult to control the strength by the direction of fiber during lamination.

Mass production is difficult and unevenness in quality occurred.

(ii) In the filament winding method, carbon fibers are reciprocated at 45º. Therefore, it is difficult to control the strength by the direction of fiber during lamination.

New Technology

・In the prepreg sheet winding method, fibers can be laminated at a desired angle of 0º to 90º, and it is possible to control the strength by application.

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 0/0; progress: 0%)

- Joint Researchers (their role)

- Ehime University (analysis/assessment)

- Example of Application

- Aircraft, automobile, medical apparatus and leisure parts (under development)

- Technical Problems

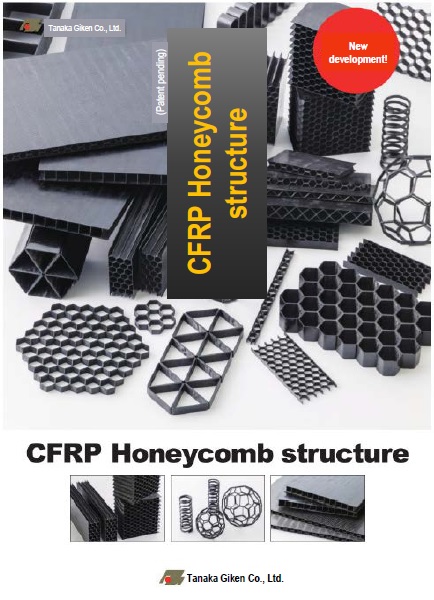

- Various carbon pipes having shapes of round, triangle, square, hexagon and so on. Long-length deformed pipe and speciallydesigned

honeycomb structure are also under study.

- Collaborator needed to Improve

- Related companies requiring honeycomb structure, long-length deformed pipe or the like.

- Technical WEB page

Inquiries

- Personnel / Department

- Research and Development department / Manager, Kazuhiko Kondo

- Address

- 433-1 Dannoue, Saijo-shi, Ehime, 799-1313 Japan

- Contact

-

TEL:+81-898-66-4011

FAX:+81-898-66-4022

Inquiry Form

Outline of Company and Organization

- Location

- 433-1 Dannoue, Saijo-shi, Ehime, 799-1313 Japan

- Contact

-

TEL:+81-898-66-4011

FAX:+81-898-66-4022

- Capital / No. of Employees

- 30,000,000 yen / 100 employees

- Product Line

- Precision processing of difficult-to-machine materials and assembly of electronic

- Major Customers

- Toray Precision Co., Ltd., Sumitomo Precision Products Co., Ltd.

- Overseas Base(s)

- None

- Certification

- JISQ9100 Aviation, space, defense

- Company/Organization WEB page

- http://www.tanakag.co.jp

Update date: 2020/1/29