NIPPON STEEL Chemical & Material Co., Ltd.

In-situ polymerization thermoplastic prepreg

In-situ polymerization thermoplastic prepreg

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ in-situ polymerization ] [ Thermoplastic carbon fiber composite ] [ thermoplastic prepreg ]

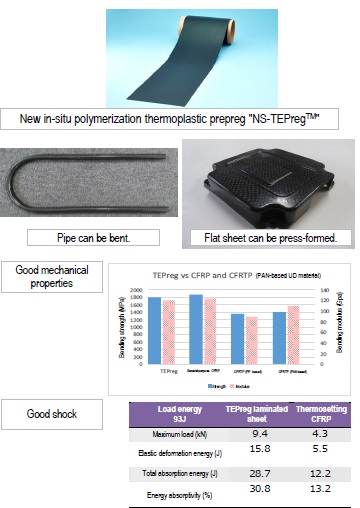

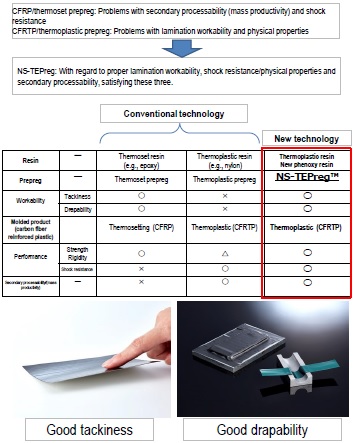

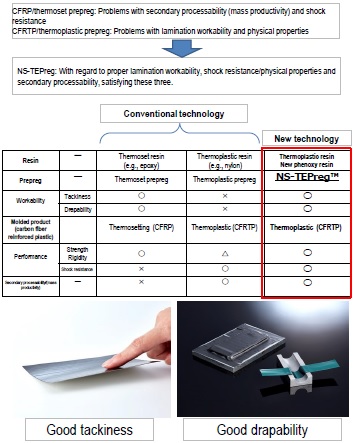

Point of the Proposed Technology

By using in-situ polymerization thermoplastic resin, a prepreg for thermoplastic carbon fiber composite having a good tackiness and adrapability equivalent to a general-purpose thermoset prepreg can be produced. Therefore, the conventional equipment for thermoset prepregcan be used as it is. Also, since a molded product is thermoplastic, it can be secondarily processed by heating and also press forming.Furthermore, it has a strength/rigidity equivalent to that of thermoset carbon fiber composite. This improved prepreg has higher workability andbetter physical properties than that of conventional thermoplastic prepregs.

Effect(s)

・Equipment for thermoset prepreg can be used.

・Allowing mass production by press

・Molded product can be finely adjusted (customized).

・Allowing mass production by press

・Molded product can be finely adjusted (customized).

Conventional Technology

There is a problem that prepregs using common thermoplastic resin have notackiness and drapability and show poor lamination workability and metalmolding performance. In addition, there has been a challenge that moldedproducts have low physical properties because the impregnation performanceinto resin is low and the adhesive property at the interface with carbon fibersis also low.

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Not published

- Example of Application

- Various sports goods, protector, enclosure, artificial limb, wheel chair and bicycle frames,automobile parts, stationery, parts for radio-controller and drone, etc.

- Technical Problems

- ・Planned to be sold in a wide variety of forms, e.g., selling in the forms of prepreg and plate material, ourcompany's selling molded products, and so on.

- Collaborator needed to Improve

- ・Sports/outdoor goods makers, electronic equipment makers, welfare/medical apparatus makers,automobile makers, hobby goods makers, etc.

- Technical WEB page

- https://www.nscm.nipponsteel.com/carbon/carbon.html

Inquiries

- Personnel / Department

- Carbon fiber composite, pitch-based carbon fiber, semiconductor electronic industrial member,metal carrier / Group Leader, Kazuya Eto

- Address

- 13-1 Nihonbashi 1-chome, Chuo-ku, Tokyo, 103-0027 Japan

- Contact

-

TEL:+81-3-3510-0343

FAX:+81-3-3510-1196

Inquiry Form

Outline of Company and Organization

- Location

- 13-1 Nihonbashi 1-chome, Chuo-ku, Tokyo, 103-0027 Japan

- Contact

-

TEL:+81-3-3510-0343

FAX:+81-3-3510-1196

- Capital / No. of Employees

- 5,000,000,000 yen / 3,200 employees (consolidated)

- Product Line

- Carbon fiber composite, pitch-based carbon fiber, semiconductor electronic industrial member, metal carrier

- Major Customers

- Overseas Base(s)

- Thailand, India, Indonesia, Philippines, Malaysia

- Certification

- ISO9001 (composite company)

- Company/Organization WEB page

- https://www.nscm.nipponsteel.com/

Update date: 2020/1/29