Nagoya Municipal Industrial Research Institute

Application of penetrant test to CFRP

Application of penetrant test to CFRP

- Technical Classification:

- [ Inspection & Analysis ]

- Products:

- Keyword:

- [ Fluorescent penetrant test ] [ surface damage ]

Point of the Proposed Technology

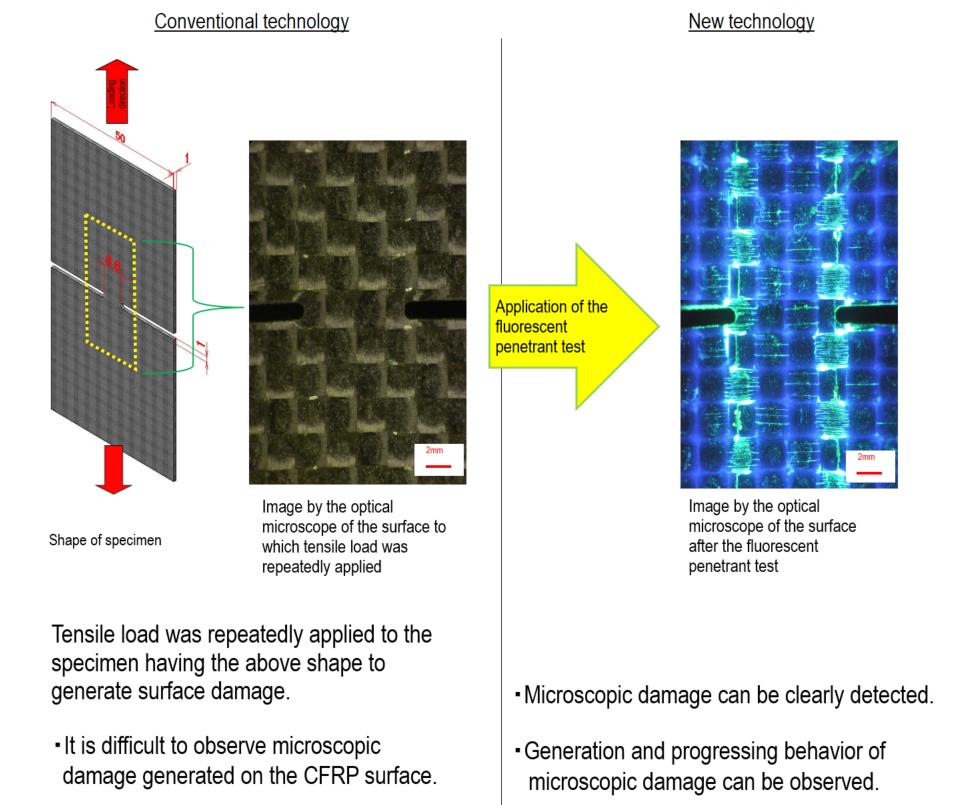

・Application of the fluorescent penetrant test to CFRP with surface damage

Effect(s)

Microscopic damage which is difficult to visually observe can be observed.

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 0/0; progress: 0%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Example of Application

- ・Observation of CFRP surface crack

- Technical Problems

- ・In order to check for damage from the surface to the inside, inspection in combination with ultrasonic test, X-ray penetrant test or the like is required.

- Collaborator needed to Improve

- ・Companies and research institutions which use generation and proceeding behavior of microscopic damage for design or the like.

・Companies and research institutions which conduct the non-destructive inspection of CFRP

- Technical WEB page

- https://www.nmiri.city.nagoya.jp/index.html

Inquiries

- Personnel / Department

- Product Evaluation Laboratory, System Technology Department / Satoshi FUKAYA

- Address

- 3-4-41, Rokuban, Atsuta-ku Nagoya-shi, Aichi, 456-0058, Japan

- Contact

-

TEL:+81-52-661-3161

FAX:+81-52-654-6788

Inquiry Form

Outline of Company and Organization

- Location

- 3-4-41, Rokuban, Atsuta-ku Nagoya-shi, Aichi, 456-0058, Japan

- Contact

-

TEL:+81-52-661-3161

FAX:+81-52-654-6788

- Capital / No. of Employees

- 0 yen / 93 employees

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.nmiri.city.nagoya.jp

Update date: 2020/1/23