RAPIIT Co., Ltd.

Development of CFRTP wheels by stamping molding

Development of CFRTP wheels by stamping molding

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ continuous fiber reinforced material moldingtechnology ] [ Integrated molding ] [ reduction of the number of parts ] [ weight reduction ]

Point of the Proposed Technology

・Use of thermoplastic composite fiber reinforced materials enables a substantial weight reduction compared to use of high-tension steel sheets or aluminum materials

・Stampable molding has enabled change in thickness, formation of ribs, etc. according to a required shape, thus realizing integrated molding.

・Enhancement of strength by the technology for flowing continuous fiber materials into every corner of a mold

・Insert molding of metal fittings or the like is also possible

・Stampable molding has enabled change in thickness, formation of ribs, etc. according to a required shape, thus realizing integrated molding.

・Enhancement of strength by the technology for flowing continuous fiber materials into every corner of a mold

・Insert molding of metal fittings or the like is also possible

Effect(s)

・Weight reduction by 30 to 45% in comparison with cast aluminum wheels

・Significant shortening of molding time in comparison with carbon fiber reinforced thermoplastic composite (CFRP ) wheels

・It is possible to make an integrated structure from a bonded structure with more parts in comparison with a CFRP wheel (by reduction of the number of parts and reduction/elimination of the bonding process, etc.)

・Significant shortening of molding time in comparison with carbon fiber reinforced thermoplastic composite (CFRP ) wheels

・It is possible to make an integrated structure from a bonded structure with more parts in comparison with a CFRP wheel (by reduction of the number of parts and reduction/elimination of the bonding process, etc.)

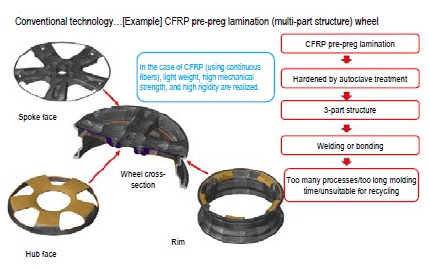

Conventional Technology

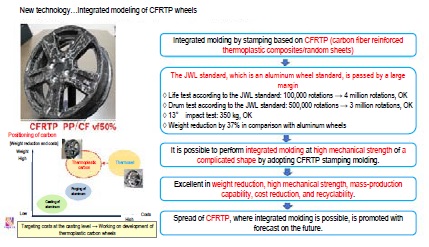

New Technology

☆It has realized integrated molding, at a shot, of a CFRTP (carbon fiber reinforced thermoplastic composite) carbon wheel by stamping molding.

☆Weight reduction by 37% has been achieved in addition to high mechanical strength that passes the aluminum wheel standards (the JWL standard).

☆Weight reduction by 37% has been achieved in addition to high mechanical strength that passes the aluminum wheel standards (the JWL standard).

Technology Deployment and Cooperation

- Development Stage

-

Development Stage

(to be completed in 2018/10; progress: 90%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Example of Application

- Automobiles, aircrafts, medical devices, general industrial parts, etc.

- Technical Problems

- ・Using thermoplastic composite fiber materials, high-strength and lightweight members are realized, which was impossible by injection molding.

・Since it allows the consideration of molding parts not in units of sub-parts but in units of welded and assembled products, a substantial weight reduction and reduction of the number of parts can be expected.

- Collaborator needed to Improve

- Universities and businesses having knowledge about composite fiber flowing technologies or material technologies

Public institutions and research organizations including universities having strength assessment technologies andequipment

- Technical WEB page

- http://www.rapiit.com/pages/about/cfrp_gfrp.html

Inquiries

- Personnel / Department

- / Representative director, Takuro Shigetomo

- Address

- 50-19 Osegi, Akaiwa-shi, Okayama, 709-0717 Japan

- Contact

-

TEL:+81-86-995-9123

FAX:+81-86-995-3444

Inquiry Form

Outline of Company and Organization

- Location

- 50-19 Osegi, Akaiwa-shi, Okayama, 709-0717 Japan

- Contact

-

TEL:+81-86-995-9123

FAX:+81-86-995-3444

- Capital / No. of Employees

- 10,000,000 yen / 28 employees

- Product Line

- Trial production of automobile sheet metal parts, trial production of composite material molding

- Major Customers

- Fiber or resin manufacturers, automobile parts manufacturers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.rapiit.com

Update date: 2020/2/26