SAKUMA SPECIAL STEEL CO., LTD.

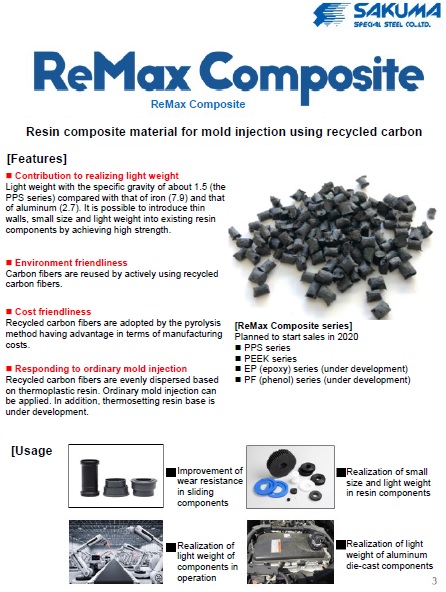

Carbon Fiber Composite Materials for Mold Injection Using Environment-Friendly Recycled Carbon Fibers

Carbon Fiber Composite Materials for Mold Injection Using Environment-Friendly Recycled Carbon Fibers

- Technical Classification:

- [ Intermediate Products ] [ Recycling ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ carbon fiber composite materials ] [ mold injection ] [ Recycled carbon fibers ]

Point of the Proposed Technology

It became possible to evenly knead recycled carbon fibers into resin by optimizing defibration, cutting, and dispersion of fibers in a kneading process.

[1] Contribution to realizing light weight: Light weight with the specific gravity of about 1.5 (the PPS series) compared with that of iron (7.9) and that of aluminum (2.7). It is possible to introduce thin walls, small size and light weight into existing resin components by achieving high strength.

[2] Environment friendliness: Carbon fibers are reused by actively using recycled carbon fibers.

[3] Cost friendliness: Recycled carbon fibers are adopted by the pyrolysis method having advantage in terms of manufacturing costs.

[4] Responding to ordinary mold injection: Recycled carbon fibers are evenly dispersed based on thermoplastic resin. Ordinary mold injection can be applied. In addition, thermosetting resin base is under development.

[1] Contribution to realizing light weight: Light weight with the specific gravity of about 1.5 (the PPS series) compared with that of iron (7.9) and that of aluminum (2.7). It is possible to introduce thin walls, small size and light weight into existing resin components by achieving high strength.

[2] Environment friendliness: Carbon fibers are reused by actively using recycled carbon fibers.

[3] Cost friendliness: Recycled carbon fibers are adopted by the pyrolysis method having advantage in terms of manufacturing costs.

[4] Responding to ordinary mold injection: Recycled carbon fibers are evenly dispersed based on thermoplastic resin. Ordinary mold injection can be applied. In addition, thermosetting resin base is under development.

Effect(s)

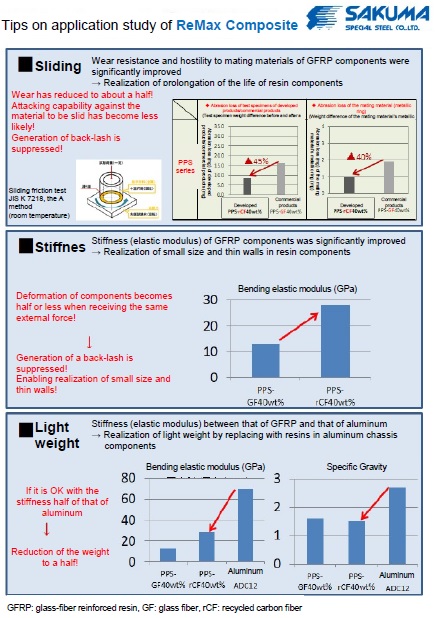

◆ Sliding: Wear resistance and attacking capability against the material to be slid of GFRP components with added glass fibers were significantly improved. → Realization of prolongation of the life of resin components.

◆ Stiffness: Stiffness (elastic modulus) of GFRP components was significantly improved. →Realization of small size and thin walls in resin components.

◆ Light weight: Stiffness (elastic modulus) between that of GFRP and that of aluminum → Realization of light weight by replacing with resins in aluminum chassis components

◆ Stiffness: Stiffness (elastic modulus) of GFRP components was significantly improved. →Realization of small size and thin walls in resin components.

◆ Light weight: Stiffness (elastic modulus) between that of GFRP and that of aluminum → Realization of light weight by replacing with resins in aluminum chassis components

Conventional Technology

For CFRP using short fibers, their components with complicated forms can bemass-produced by mold injection, but they are not widely used as virgincarbon fibers (CF) are expensive.

In addition, there is a concern that environmental burdens will increase in thefuture due to disposal of CFRP.

In addition, there is a concern that environmental burdens will increase in thefuture due to disposal of CFRP.

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 2020/12; progress: 70%)

- Intellectual Property Right

- Applying

- Joint Researchers (their role)

- Sanyo Kako Co., Ltd. (role: test production by kneading)

- Example of Application

- Components where wear resistance, stiffness or light weight is required in the fields of automobiles andindustrial equipment (GFRP components with added glass fibers, aluminum die-cast replacement, etc.)

- Technical Problems

- Durability assessment of developed CFRTP

- Collaborator needed to Improve

- Mold injection manufacturers producing components using CFRTP pellets

- Technical WEB page

- https://www.sakuma-ss.co.jp/news/20191010/

Inquiries

- Personnel / Department

- Technical Service / Group General Manager, Toshiaki Terada

- Address

- 5-250 Urasato, Midori-ku, Nagoya-shi, Aichi, 458-8510 Japan

- Contact

-

TEL:+81-52-623-5553

FAX:+81-52-623-5558

Inquiry Form

Outline of Company and Organization

- Location

- 5-250 Urasato, Midori-ku, Nagoya-shi, Aichi, 458-8510 Japan

- Contact

-

TEL:+81-52-623-5551

FAX:+81-52-623-5558

- Capital / No. of Employees

- 360,000,000 yen / 167employees

- Product Line

- Sales/supply of special steel materials, high alloy materials, next-generation materials, and processed components

- Major Customers

- Overseas Base(s)

- Thailand, China, Indonesia, USA

- Certification

- Company/Organization WEB page

- https://www.sakuma-ss.co.jp/

Update date: 2020/1/30