Tsudakoma Corp.

Axial UD prepreg roll production system

Axial UD prepreg roll production system

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ Minimizing cycle time of lay-up process by using axial UD roll ]

Point of the Proposed Technology

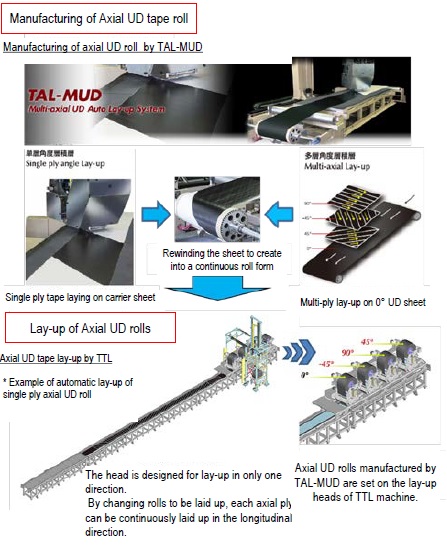

1. Prepregs are continuously laid up on a carrier sheet such as backing paper, and the laid-up prepregs are wound into a roll form to manufacture a single-ply axial UD roll.

2. Prepregs are laid up in multiple layers at the required angles, and the laid-up prepregs are wound into a roll form to manufacture a multi-ply/multi-axial UD roll.

3. Use of angle UD rolls in the lay-up process allows a simplified lay-up of angle layers.

2. Prepregs are laid up in multiple layers at the required angles, and the laid-up prepregs are wound into a roll form to manufacture a multi-ply/multi-axial UD roll.

3. Use of angle UD rolls in the lay-up process allows a simplified lay-up of angle layers.

Effect(s)

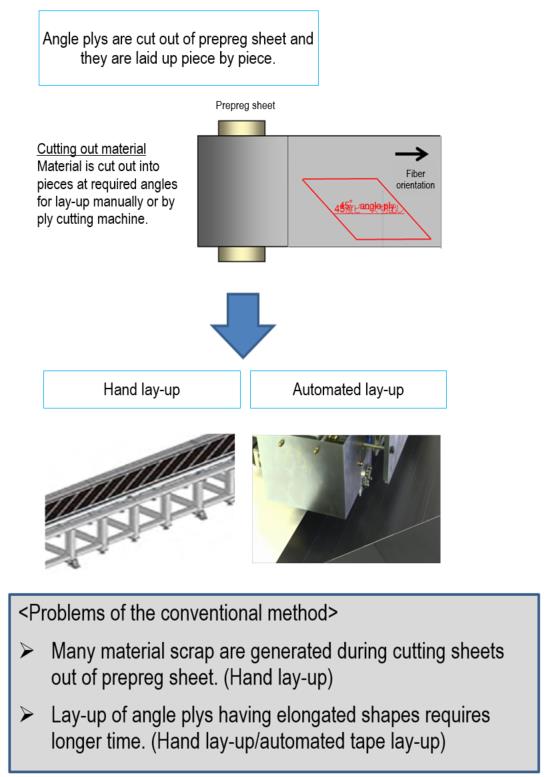

Less material scrap generation

Cost reduction by simplification of the lay-upmachine

Reduction of the lay-up cycle time

Cost reduction by simplification of the lay-upmachine

Reduction of the lay-up cycle time

Conventional Technology

New Technology

Video of the Proposed Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Example of Application

- ・Mass production line for long structural parts for aircrafts

・Use of axial UD rolls as the sheet winding molding materials for cylindrical molded parts

- Technical Problems

- Axial UD roll is produced off-line (out of manufacturing line) and supplied as base material to the manufacturing line process.Establishment of a supply chain for manufacturing and selling axial UD rolls

- Collaborator needed to Improve

- Companies and research institutions including universities having the know-how about molding andprocessing of CFRP materials

- Technical WEB page

- http://www.tsudakoma.co.jp/composite/japanese/index.html

Inquiries

- Personnel / Department

- Sales, Service and Marketing Section, Composite Machinery Department / Hiroshi Ichikawa, Takuya Minami

- Address

- 5-18-18 Nomachi, Kanazawa-shi, Ishikawa, 921-8650 Japan

- Contact

-

TEL:+81-76-242-1116

FAX:+81-76-244-9459

Inquiry Form

Outline of Company and Organization

- Location

- 5-18-18 Nomachi, Kanazawa-shi, Ishikawa, 921-8650 Japan

- Contact

-

TEL:+81-76-242-1116

FAX:+81-76-244-9459

- Capital / No. of Employees

- 12,316,540,000 yen / 961 employees

- Product Line

- Composite material processing machines, weaving machines, round table for machine tool

- Major Customers

- Domestic large heavy industries, etc.

- Overseas Base(s)

- China, India

- Certification

- ISO9001, ISO14001, EN9100

- Company/Organization WEB page

- http://www.tsudakoma.co.jp

Update date: 2020/2/12