MIE METAL INDUSTRY CO., LTD.

Weight reduction of structural parts such as used in vehicle

Weight reduction of structural parts such as used in vehicle

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ 500% increase of the structural strength ] [ 80% reduction of weight ] [ as compared to steel components ] [ Improvement of fuel economy by weight reduction ]

Point of the Proposed Technology

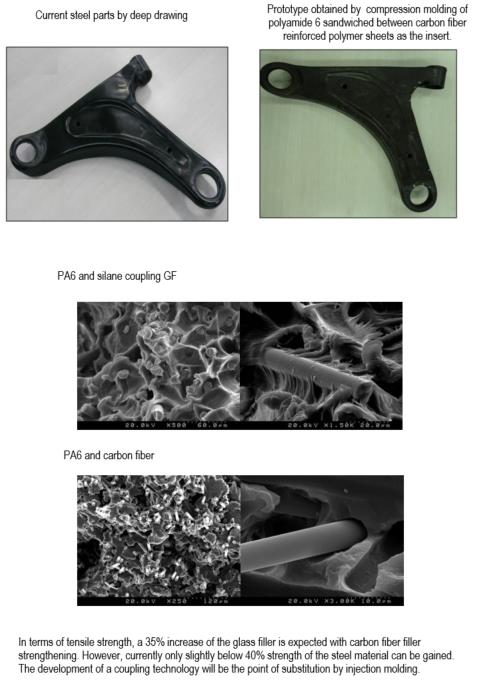

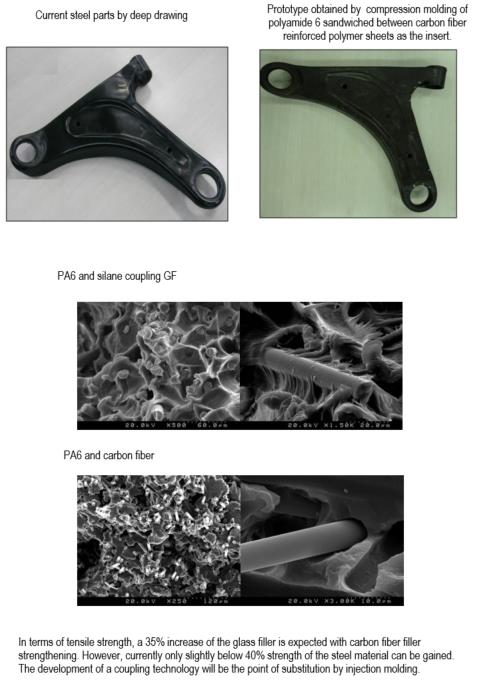

Current knowledge is based on the older technology before improving adhesion of the carbon fiber reinforced polymer sheet and its development is temporally put on hold because the structural strength targeted was not achieved, but a mold for insert molding of the carbon fiber reinforced polymer sheet is available.

Effect(s)

Weight reduction by 80% as compared to steel products

Structural strength targeted was not achieved when using the sheet before improvement of the adhesion of the insert sheet

Structural strength targeted was not achieved when using the sheet before improvement of the adhesion of the insert sheet

Conventional Technology

Design and manufacture of the metal progressive die

Metal stamping and forming

Design and manufacture of the direct-pressure type and injection molding die for resins

Molding of resins

Insert molding

Metal insert

Joining insert to the metal part⇒injection to the consecutive metal part

Design and manufacture of automated processing equipment

Ultrasonic welding, fusion, welding, joining by crimping, laser processing, assembly

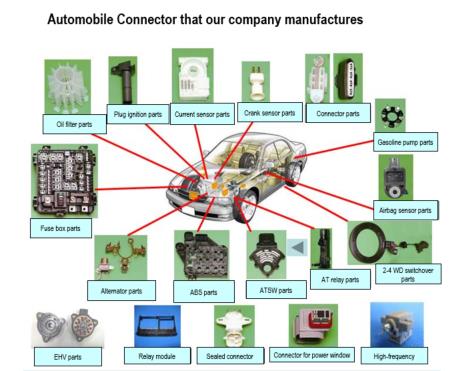

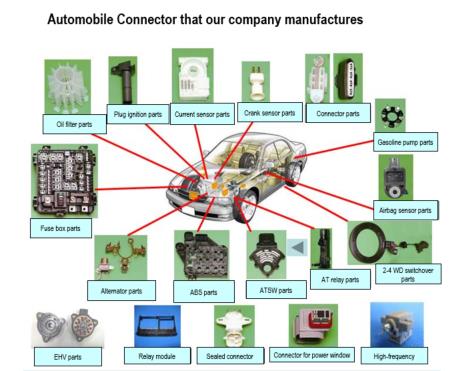

* Manufacture of molded parts for the automotive electrical and electronic system

* Manufacture of molded parts for medical devices

* Manufacture and sale of medical assistive devices

Metal stamping and forming

Design and manufacture of the direct-pressure type and injection molding die for resins

Molding of resins

Insert molding

Metal insert

Joining insert to the metal part⇒injection to the consecutive metal part

Design and manufacture of automated processing equipment

Ultrasonic welding, fusion, welding, joining by crimping, laser processing, assembly

* Manufacture of molded parts for the automotive electrical and electronic system

* Manufacture of molded parts for medical devices

* Manufacture and sale of medical assistive devices

New Technology

A resin molded part is sandwiched between carbon fiber reinforced polymer sheets as an insert and then compressed to form a structural part with high strength without use of metal.

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 0/0; progress: 30%)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Mie University for evaluation of properties

- Example of Application

- Weight reduction by using only resin as the structural material. Higher flexibility in design

*Insert molding technology in which thick wall parts can be sandwiched between carbon fiber reinforced polymer sheets.

- Technical Problems

- Use of only resin in automotive structural parts. Shortening of the residence time in molding using high damping effects with the robotic arm.

- Collaborator needed to Improve

- We would like to cooperate with the carbon fiber manufactures for improving the adhesion to the polymer.

- Technical WEB page

- http://www.miekin.co.jp/technology/item.html

Inquiries

- Personnel / Department

- Sales Department / Kenji Tokuda

- Address

- 564-1, Handa, Tsu-shi, Mie, 514-0823 Japan

- Contact

-

TEL:059-228-0101

FAX:059-228-0105

Inquiry Form

Outline of Company and Organization

- Location

- 564-1, Handa, Tsu-shi, Mie, 514-0823 Japan

- Contact

-

TEL:+81-59-228-0101

FAX:+81-59-228-0105

- Capital / No. of Employees

- 70,000,000 yen / 400 employees

- Product Line

- Connectors for vehicle

- Major Customers

- Denso Corporation, Sumitomo Wiring Systems Ltd., Panasonic Corporation

- Overseas Base(s)

- Shanghai China, Hanoi Vietnam

- Certification

- ISO9001 ISO14001

- Company/Organization WEB page

- http://www.miekin.co.jp

Update date: 2020/2/26