IHI Logistics & Machinery Corporation

CFRTP mold forming system

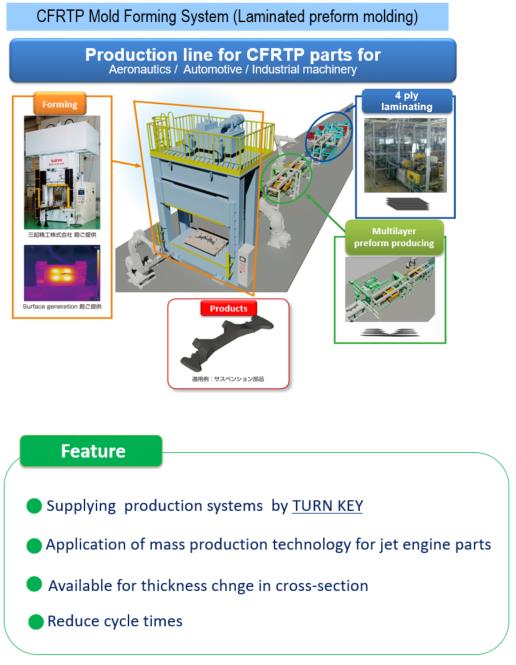

CFRTP mold forming system

- Technical Classification:

- [ Molding ]

- Products:

- [ Equipment / Facilities ] [ Service ]

- Keyword:

- [ Automation of manufacture of thermoplastic CFRP parts ]

Point of the Proposed Technology

Automated CFRTP mold forming system with UD CFRTP prepreg sheets

Effect(s)

Achievement of integrated production

Mass production

Stabilization of quality

Mass production

Stabilization of quality

Conventional Technology

・Manual work

( Cutting and Laminating prepregs Setting preforms into the mold )

or

・Cell production system using stand-alone equipment

( Cutting and Laminating prepregs Setting preforms into the mold )

or

・Cell production system using stand-alone equipment

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: no)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- None

- Example of Application

- Mass production of CFRTP (thermoplastic ) parts

- Technical Problems

- <Constraints> Poor availability (not distributed) of CFRTP( thermoplastic ) prepreg as material

<Business plan> Providing a manufacturing line through tie-up with a material manufacturer

- Collaborator needed to Improve

- End users/individual equipment manufacturers considering mass production

- Technical WEB page

- https://www.ihi.co.jp/ilm/products/car_fa/index.html#fa02

Inquiries

- Personnel / Department

- Project Management Group, Automotive FA Department Project Division / Takahiro ONIWA

- Address

- Toyosu IHI Building, 1-1, Toyosu 3-chome, Koto-ku, Tokyo 135-0061, Japan

- Contact

-

TEL:+81-3-6204-8173

Inquiry Form

Outline of Company and Organization

- Location

- 465-0025 Toyosu IHI Building, 1-1, Toyosu 3-chome, Koto-ku, Tokyo 135-0061, Japan

- Contact

-

TEL:+81-3-6204-8181

FAX:+81-3-6204-8855

- Capital / No. of Employees

- 1,000,000,000 yen / 642 employees

- Product Line

- logistic system, FA system, industry machinery, service maintenance,etc.

- Major Customers

- logistic, display, automobile, rubber, plastics-related manufacturers, etc.

- Overseas Base(s)

- Europe, Asia, etc.

- Certification

- Company/Organization WEB page

- http://www.ihi.co.jp/ilm/

Update date: 2020/2/18