SEIDENSHA ELECTRONICS CO., LTD.

Welding/fusion cutting between molded parts using thermoplastic CFRTP

Welding/fusion cutting between molded parts using thermoplastic CFRTP

- Technical Classification:

- [ Joining ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ Automation ] [ fusion technology ] [ low cost ] [ mass production ] [ short time ] [ Welding technology ]

Point of the Proposed Technology

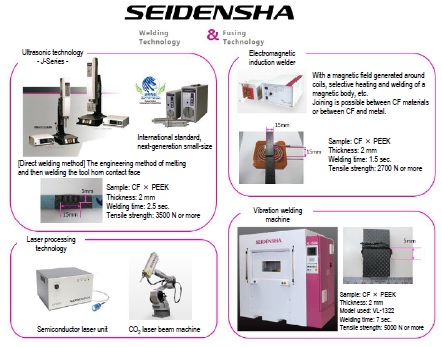

・Engineering method proposal and provision of facilities by the general manufacturer of welding/fusion cutting equipment targeting thermoplastic resin

⇒ Welding/fusing cutting by ultrasonic vibration, electromagnetic induction heating, hot plate welding (contact/non-contact type), high-frequency welding, vibration welding, laser beam processing (welding/fusion cutting), spin welding, ultrasonic metal joining technology, etc.

⇒ Welding/fusing cutting by ultrasonic vibration, electromagnetic induction heating, hot plate welding (contact/non-contact type), high-frequency welding, vibration welding, laser beam processing (welding/fusion cutting), spin welding, ultrasonic metal joining technology, etc.

Effect(s)

・ Mass production

・Automatic equipment

・Shortening of man-hour and processing time

・Improvement of recyclability

・Automatic equipment

・Shortening of man-hour and processing time

・Improvement of recyclability

Conventional Technology

Thermoplastic CFRP can be joined by thermal welding, but the thermalwelding technology is wide-ranging, and it is difficult to select the optimumwelding technology.

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Joint Researchers (their role)

- NCC/Nagoya University (Role: CFRTP welding evaluation)

ICC/Kanazawa Institute of Technology (Role: CFRTP welding evaluation)

The University of Tokyo (Role: CFRTP welding evaluation)

Gifu Prefectural Industrial Technology Center (Role: CFRTP welding evaluation)

- Example of Application

- Welding processing of thermoplastic CFRP products applicable to any industry

- Technical Problems

- Optimal engineering methods in terms of thermoplastic resin molded products or metal joining will beproposed from various engineering methods possessed by our company.

- Collaborator needed to Improve

- Businesses in manufacturing or handling resin molded products.

- Technical WEB page

- https://www.sedeco.co.jp/item/

Inquiries

- Personnel / Department

- Nagoya District Sales Office/Sales Division, West Japan Branch / General Manager, Shuhei Hasegawa/Engineer, Atsuki Seki

- Address

- 271 Matsui-cho, Meito-ku, Nagoya-shi, Aichi, 465-0062 Japan/5-15 Ikutamamae-machi, Tennoji-ku, Osaka-shi, Osaka, 543-0072 Japan

- Contact

-

TEL:+81-52-709-6321/+81-06-6772-7451

Inquiry Form

Outline of Company and Organization

- Location

- 2-2-17 Nishinippori, Arakawa-ku, Tokyo, 116-0013 Japan

- Contact

-

TEL:+81-3-3802-5101

FAX:+81-3-3807-6259

- Capital / No. of Employees

- 88,630,000 yen / 170 employees

- Product Line

- Thermoplastic resin welding/fusion equipment, and automated equipment

- Major Customers

- Automobiles, electric equipment, electronic communication system, optics, medical treatment, chemistry, foods, etc.

- Overseas Base(s)

- U.S., China, Thailand

- Certification

- ISO9001

- Company/Organization WEB page

- http://www.sedeco.co.jp/

Update date: 2020/2/27