SUGINO MACHINE LIMITED

Difficult-to-cut materials applying water jet technology

Difficult-to-cut materials applying water jet technology

- Technical Classification:

- [ Processing ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ Complex shape processing ] [ Difficult-to-cut materials (regardless of materials and shapes) ] [ Heat effects ] [ Water jet ]

Point of the Proposed Technology

・Using water jet, instead of conventional machine processing and laser processing, can ensure contactless and high density and can help minimizing deformation and strain of the workpiece.

Effect(s)

・Prolongs tool life

・Improves precision of processed surface

・Improves precision of processed surface

Conventional Technology

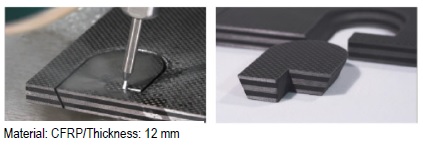

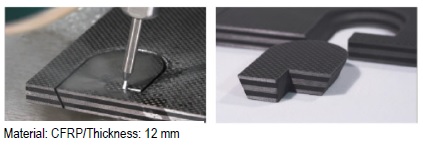

Example of application to CFRP

Laser cutting:

・There are resin parts and fiber parts in CFRP. Using laser in cutting CFRP caused dissolution only in the resin parts, which made cutting difficult.

Cutting with metal tool:

・ In processing composite materials such as CFRP, it is difficult to process fibers, leading to shorter tool life. In addition, when worn-out tool is used for processing, cutting face of the work piece becomes deteriorated.

Laser cutting:

・There are resin parts and fiber parts in CFRP. Using laser in cutting CFRP caused dissolution only in the resin parts, which made cutting difficult.

Cutting with metal tool:

・ In processing composite materials such as CFRP, it is difficult to process fibers, leading to shorter tool life. In addition, when worn-out tool is used for processing, cutting face of the work piece becomes deteriorated.

New Technology

Example of application to CFRP

Water jet:

・ Water jet does not cause resin dissolution by the heat and it can make stable surface.

・ As per contactless and high density processing, minimum deformation and strain on the workpiece is enabled. Owing to cutting with an aqueous medium, dust scattering can be prevented.

Water jet:

・ Water jet does not cause resin dissolution by the heat and it can make stable surface.

・ As per contactless and high density processing, minimum deformation and strain on the workpiece is enabled. Owing to cutting with an aqueous medium, dust scattering can be prevented.

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Example of Application

- ・ Cutting and drilling for CFRP and molding parts of plastic.

- Technical Problems

- ・ A proposal is needed for the processing method to reduce the amount of abrasive materials to be used.

・ Improvement aimed at processing with higher pressure of the jet.

- Collaborator needed to Improve

- ・Manufacturers of high-strength metal, ceramics, and resins

- Technical WEB page

- http://www.sugino.com/water-jet-cutting-system2/

Inquiries

- Personnel / Department

- Plant Equipment Division / Yoshitaka Tsuji

- Address

- AI Takadake Bldg., 4-13 Higashisakura 1-chome, Higashi-ku, Nagoya-shi, Aichi, 461-0005 Japan

- Contact

-

TEL:+81-52-973-3070

FAX:+81-52-973-3077

Inquiry Form

Outline of Company and Organization

- Location

- 2410 Hongo, Uozu-shi, Toyama, 937-8511 Japan

- Contact

-

TEL:+81-765-24-5111

FAX:+81-765-24-5051

- Capital / No. of Employees

- 2,324,670,000 yen / 1630 employees(Whole group)

- Product Line

- Ultra-high pressure water cutting device, wet/dry atomizing unit, drilling unit, etc.

- Major Customers

- Overseas Base(s)

- USA, Mexico, France, Germany, China, Thailand, Singapore, Indonesia, etc.

- Certification

- Company/Organization WEB page

- http://www.sugino.com/index-e.html

Update date: 2020/1/30