HIRATA PRECISION INDUSTRIAL JAPAN INC.

Development of a carbon fiber composite CFRP forming system for mass-production

Development of a carbon fiber composite CFRP forming system for mass-production

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ double-acting control servo press (ZEN Former) ] [ GMS heat press forming ] [ high-precision CFRP parts ]

Point of the Proposed Technology

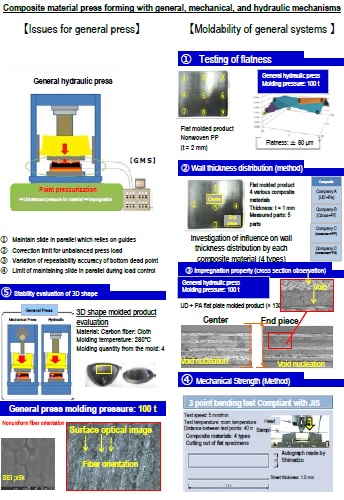

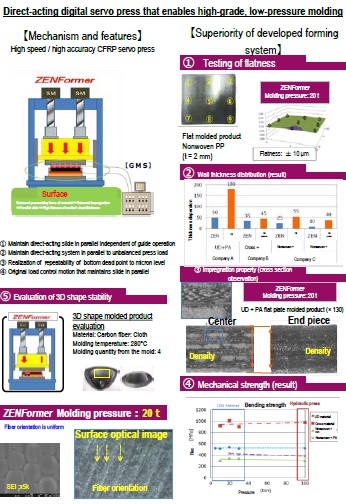

Solving issues with the thermal press forming in conventional CFRP carbon fiber composite material

By maximizing the press capacity of 【Mold H & C temperature control system: GMS】and【4-axis direct-acting digitalservo press: ZENFormer】, our company has developed a mass production forming system that enables highquality/high cycle forming. We introduce the superiority supported by formability evaluation.

By maximizing the press capacity of 【Mold H & C temperature control system: GMS】and【4-axis direct-acting digitalservo press: ZENFormer】, our company has developed a mass production forming system that enables highquality/high cycle forming. We introduce the superiority supported by formability evaluation.

Effect(s)

・Improvement of forming quality

・Improvement in productivity by high cycle

・Strengthen of cost competitiveness

・Integration of forming data combined with IoT

・Improvement in productivity by high cycle

・Strengthen of cost competitiveness

・Integration of forming data combined with IoT

Conventional Technology

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: no)

- Intellectual Property Right

- None

- Joint Researchers (their role)

- Go-factory Ltd.: Development of H & C mold temperature control system

Hoden Seimitsu Kako Kenkyusho Co. Ltd.,: System development as a facility for composite material ofdirect-acting servo press ZENFormer

- Example of Application

- ・Industrial parts requiring weight reduction of increase in strength

(Target markets: Next-generation automobile, medical device, natural energy, industrial robot, OA composite machine, smart tabletterminal, etc.)

- Technical Problems

- Accumulation of know-hows based on elemental technologies and trial & error method, increase of mold scale, verification ofmaximum control capability, and so on

- Collaborator needed to Improve

- Makers, research and development organization, etc. with which we can cooperate toward establishment of integrated productionsystem of upstream processes for composite materials and intermediate materials and downstream processes such as secondaryprocessing, jointing and decorating

- Technical WEB page

- http://www.hirataprecision.jp/innovation/

Inquiries

- Personnel / Department

- / President, Terumasa Hirata

- Address

- 57-3 Koyama, Sakado-shi, Saitama, 350-0257 Japan

- Contact

-

TEL:+81-49-283-2323

FAX:+81-49-283-2006

Inquiry Form

Outline of Company and Organization

- Location

- 57-3 Koyama, Sakado-shi, Saitama, 350-0257 Japan

- Contact

-

TEL:+81-49-283-2323

FAX:+81-49-283-2006

- Capital / No. of Employees

- 10,000,000 yen / 50 employees

- Product Line

- Sale and manufacturing of industrial plastic products design and design and manufacturing of molds

- Major Customers

- E/U, Tier makers in various industries

- Overseas Base(s)

- China (Dalian), Vietnam (Ho Chi Minh)

- Certification

- ISO9001:2008, ISO14001:2004

- Company/Organization WEB page

- http://www.hirataprecision.jp/

Update date: 2020/2/26