NIPPON STEEL Chemical & Material Co., Ltd.

Thermoplastic carbon fiber mesh material

Thermoplastic carbon fiber mesh material

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ knit fabric ] [ Thermoplastic carbon fiber composite material ]

Point of the Proposed Technology

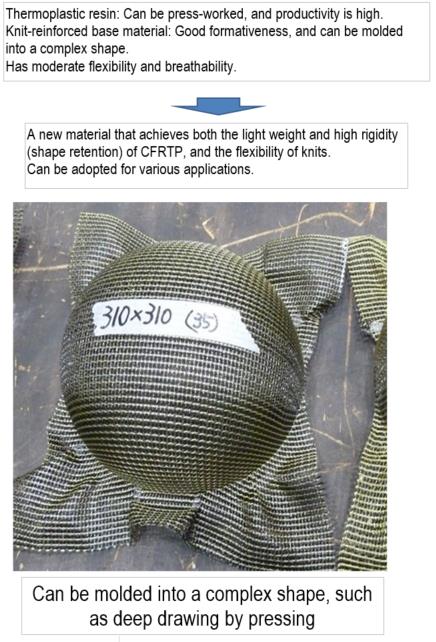

Since the product uses a knit fabric as the reinforcement base material and a thermoplastic resin as the matrix, it excels in pressworkability and can be worked into a complex shape such as deep drawing. While having lightweight/high-rigidity characteristicsof carbon fiber composites, it also has breathability and flexibility of mesh material. The company succeeded in impregnating aknit-reinforced base material with a thermoplastic resin, which was previously difficult to achieve, by using a special thermoplasticresin.

Effect(s)

・Enables mass production through cold pressing

・Working of complex shapes

・Working of complex shapes

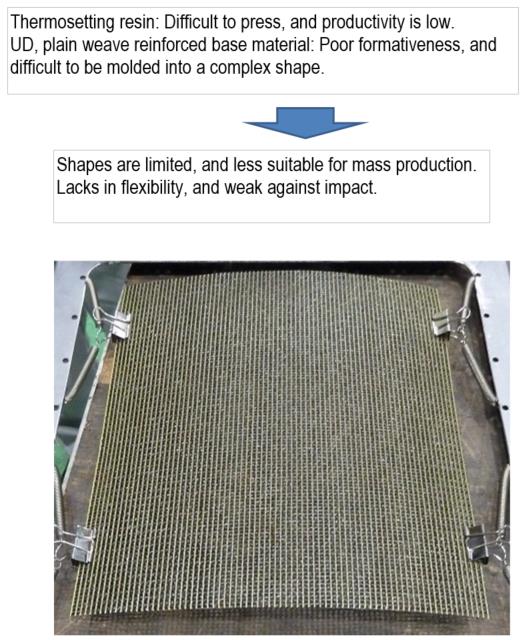

Conventional Technology

In the case of common thermoplastic resin, the melt viscosity of resin washigh, and thus resin impregnation into knit fabric was difficult.In addition, mesh-like products could not be manufactured due to clogginggenerated in knit fabric.

New Technology

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: no)

- Intellectual Property Right

- Applying

- Joint Researchers (their role)

- SHINDO: base material production

- Example of Application

- Various cap inners, sport protectors, protective clothing, apparel (bags, shoes)

home fabric (desks, chairs), structures (tents, geotextile), etc.

- Technical Problems

- ・Planning sale in both material selling, and molding selling at our company.

- Collaborator needed to Improve

- ・Companies related to sports, outdoor, protective equipment, medical, and apparel

- Technical WEB page

- https://www.nscm.nipponsteel.com/carbon/carbon.html

Inquiries

- Personnel / Department

- Industrial Composite Materials & TEPreg Development Gr. Composite Development Dept. Composite Div. / Group Leader, Kazuya Eto

- Address

- 13-1 Nihonbashi 1-chome, Chuo-ku, Tokyo, 103-0027 Japan

- Contact

-

TEL:+81-3-3510-0343

FAX:+81-3-3510-1196

Inquiry Form

Outline of Company and Organization

- Location

- 13-1 Nihonbashi 1-chome, Chuo-ku, Tokyo, 103-0027 Japan

- Contact

-

TEL:+81-3-3510-0343

FAX:+81-3-3510-1196

- Capital / No. of Employees

- 5,000,000,000 yen / 3,200 employees (consolidated)

- Product Line

- Carbon fiber composite, pitch-based carbon fiber, semiconductor electronic industrial member, metal carrier

- Major Customers

- Overseas Base(s)

- Thailand, India, Indonesia, Philippines, Malaysia

- Certification

- ISO9001 (composite company)

- Company/Organization WEB page

- https://www.nscm.nipponsteel.com/

Update date: 2020/2/12