IPCO K.K.

Continuous Sheet Forming of Thermoplastic CFRP Pre-pregs

- Technical Classification:

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ Carbon fibers ] [ continuous ] [ forming ] [ Impregnation ] [ pressing ] [ steel belts ]

Point of the Proposed Technology

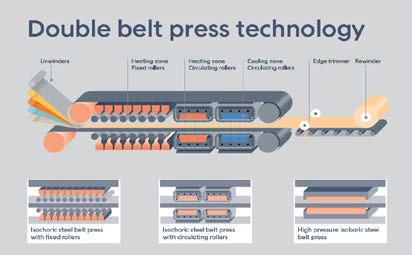

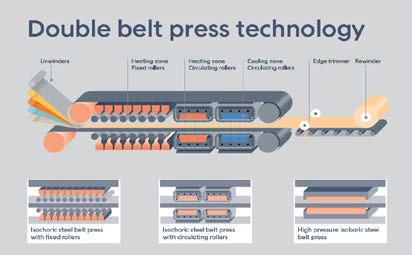

We propose the equipment for continuous production of pre-pregs needed for mass production of carbon fiberproducts. Application of double-belt presses with steel belts enables production of long pre-preg sheets. Inproducing carbon fiber pre-pregs, processing at specific temperature and pressure for a certain constant period oftime is indispensable to allow full impregnation, which is realized by use of double-belt presses.

Effect(s)

Enhancement of productivity inmanufacturing of thermoplastic CFRPpre-pregs

Conventional Technology

Manufacturing of constant-length materials by use of batchpressing or manufacturing of single items of products bythe RTM method (neither of them is suitable for massproduction)

New Technology

Double-belt presses with steel belts is used so as to makeconsecutive continuous forming of thermoplastic CFRP pre-pregs. Since it is possible to use it in next processing aslong sheets, application to final product forming is widelyopen. In addition, mass production becomes possible, andcontribution to reduction of production costs is achieved.

In the impregnation process of pre-pregs, selection ofprocessing conditions suitable for the material and designof pressing equipment corresponding to these conditionsbecome important. The press conditions include theelements of temperature, pressure, and detention time,and by combining necessary conditions, it becomespossible to combine optimal press modules and providepress equipment.

Technology Deployment and Cooperation

- Development Stage

-

Commercialization Completed (already delivered: yes)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Practitioner:The Innovative Composite Center, Kanazawa Institute of Technology

Role: Assessment of forming result for practical application and necessary improvement of devices

- Example of Application

- * Automobile components in which mass production is required, and large components such as buildingmaterials

- Technical Problems

- * To find out CFRP needs in which mass production is required

* To find out CFRP application that can be realized as large components

- Collaborator needed to Improve

- * CFRP material manufacturers, CFRP forming manufacturers

- Technical WEB page

- https://ipco.com/jp/products/プレス方式/

Inquiries

- Personnel / Department

- CS Business Development Dept. / Manager, Hiroshi Nunogakii

- Address

- 1-18 Mitsugaoka, Nishi-ku, Kobe-shi, Hyogo, 651-2228 Japan

- Contact

-

TEL:+81-78-570-1401

FAX:+81-78-570-1402

Inquiry Form

Outline of Company and Organization

- Location

- 1-18 Mitsugaoka, Nishi-ku, Kobe-shi, Hyogo, 651-2228 Japan

- Contact

-

TEL:+81-78-570-1401

FAX:+81-78-570-1402

- Capital / No. of Employees

- 300,000,000 yen / 40 employees

- Product Line

- Steel belts (including specular working), double-belt presses, conveyor systems, cooling systems, and granulation equipment

- Major Customers

- Food manufacturers, board manufacturers, chemical manufacturers, etc.

- Overseas Base(s)

- Sweden, Germany, England, France, Netherlands, Italy, USA, Canada, China, South Korea, Singapore, etc.

- Certification

- ISO9001/14001/18001

- Company/Organization WEB page

- https://ipco.com/jp/

Update date: 2020/2/23