Japan Fine Ceramics Center

Recovery of carbon fibers from CFRP and surface modification of the fibers using superheated steam

Recovery of carbon fibers from CFRP and surface modification of the fibers using superheated steam

- Technical Classification:

- [ Recycling ]

- Products:

- Keyword:

- [ fiber surface modification ] [ recycle ] [ superheated steam ]

Point of the Proposed Technology

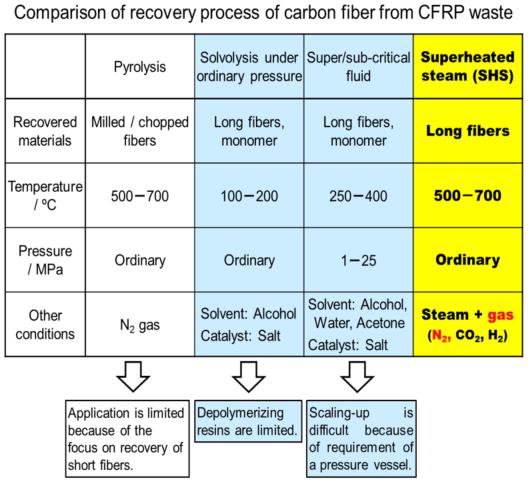

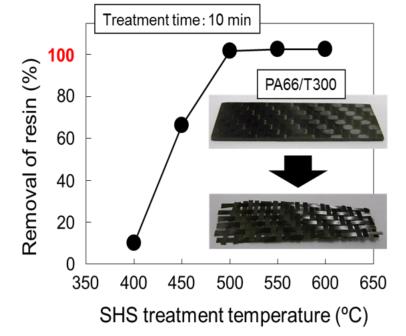

・Matrix resin of CFRP is decomposed and vaporized by superheated steam treatment, and various lengths and states of carbon fibers can be recovered.

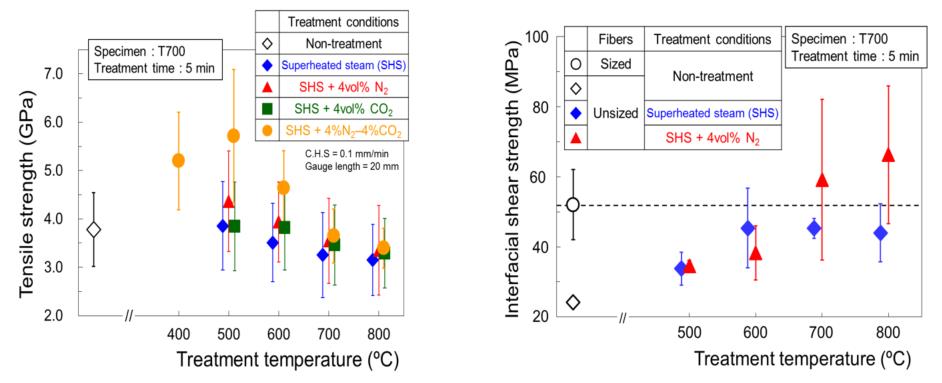

・Superheated steam treatment with process gases (N2, etc) enables the surface modification of fibers (improvement in adhesion between fiber and resin, increase in fiber strength).

・Superheated steam treatment with process gases (N2, etc) enables the surface modification of fibers (improvement in adhesion between fiber and resin, increase in fiber strength).

Effect(s)

Lowering of CFRP reproduction costs

Conventional Technology

New Technology

・ Various lengths and states of carbon fiber can be recovered by SHS treatment.

・ SHS treatment with process gas (N2, etc) enables the surface modification of fibers (improvement in adhesion between fiber and resin, increase in fiber strength).

・ SHS treatment with process gas (N2, etc) enables the surface modification of fibers (improvement in adhesion between fiber and resin, increase in fiber strength).

Technology Deployment and Cooperation

- Development Stage

-

Prototyping / experimental Stage

(to be completed in 2018/3; progress: 90%)

- Intellectual Property Right

- Yes

- Joint Researchers (their role)

- Takasago Industry Co., Ltd.

(role: development of low cost and mass processing system)

- Example of Application

- ・Fiber recycling from various CFRP and fiber surface modification

- Technical Problems

- ・Processing capacity and cost are poor due to the current batch and electric heating type system.

・Continuous-type low cost and mass processing system is under development.

・Not sufficient in application development of the recycled carbon fiber.

- Collaborator needed to Improve

- ・CFRP part manufacturers

- Technical WEB page

- http://www.jfcc.or.jp/38_materials/

Inquiries

- Personnel / Department

- Materials Research and Development Laboratory / Researcher, Masashi Wada

- Address

- 2-4-1 Mutsuno, Atsuta-ku, Nagoya, Aichi, 456-8587 Japan

- Contact

-

TEL:+81-52-889-1666

FAX:+81-52-871-3599

Inquiry Form

Outline of Company and Organization

- Location

- 2-4-1 Mutsuno, Atsuta, Nagoya, Aichi, 456-8587, Japan

- Contact

-

TEL:+81-52-871-3500

FAX:+81-52-871-3505

- Capital / No. of Employees

- 0 yen / 86 employees

- Product Line

- Major Customers

- Overseas Base(s)

- Certification

- Company/Organization WEB page

- http://www.jfcc.or.jp/en/

Update date: 2020/3/16