ASANO LABORATORIES CO., LTD.

Heating of a CFRTP sheet using a high-response IR heater

- Technical Classification:

- [ Molding ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ mid-infrared heater ] [ Preliminary heating ] [ sheet temperature control ] [ sheet temperature distribution adjustment ]

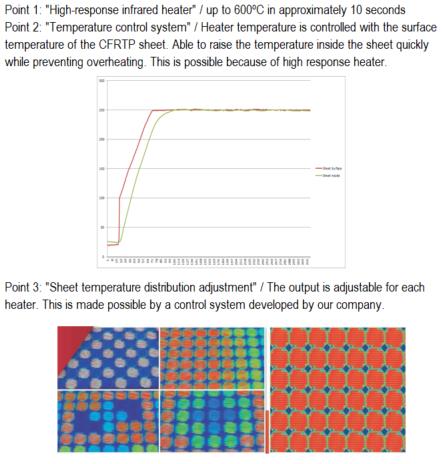

Point of the Proposed Technology

1. Domestically produced heater and temperature control system developed by our company for heating thermoplastic resin sheets

2. In addition to the overheating control of the sheet, temperature difference suppression of the thickness direction of the sheet is possible.

3. Adjustment of sheet temperature distribution by output adjustment for each heater

2. In addition to the overheating control of the sheet, temperature difference suppression of the thickness direction of the sheet is possible.

3. Adjustment of sheet temperature distribution by output adjustment for each heater

Effect(s)

1. Quality improvement

2. Moldability improvement

3. Cycle shortening

2. Moldability improvement

3. Cycle shortening

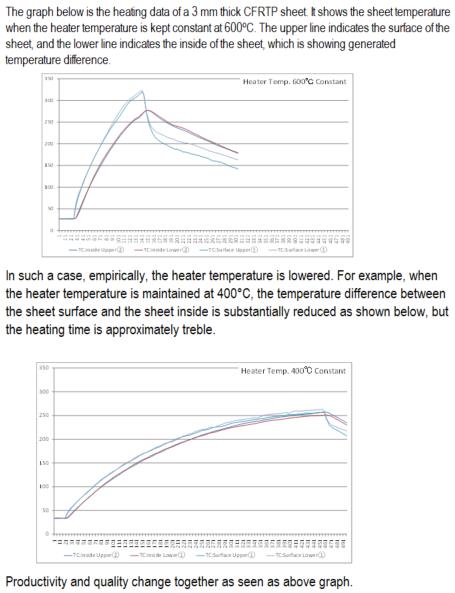

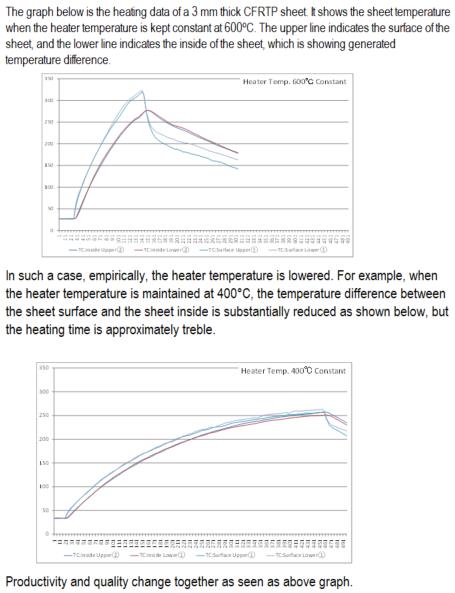

Conventional Technology

To shorten the heating time, usually set temperature of the heater higher. For example, during the use of high temperature heater, the surface of the sheet rises to the desired temperature quickly, but the inside of the sheet will still be under-heated, just like a half-raw cooked food. If you wait until the temperature of both the sheet and the inside are heated, the surface of the sheet will be damaged by overheating, just like a burnt food.

New Technology

Although the thermoplastic resin is used for the CFRTP sheet, it is necessary to understand that the infrared ray absorption characteristic is quite different from ordinary thermoplastic resin. The Quick Response Heater System that our company developed has the following features.

Technology Deployment and Cooperation

| Development Stage |

Commercialization Completed (already delivered: yes) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Yes | ||||

| Joint Researchers (their role) | |||||

| Example of Application | Preliminary heating of the Carbon Fiber Reinforced Thermoplastics (CFRTP)

| ||||

| Technical Problems | ・Aiming at shortening of the preliminary heating time

・Fully automating the overheating suppression and control | ||||

| Collaborator needed to Improve | Molding machine manufacturers, engineering companies

| ||||

| Technical WEB page | http://www.asano-lab.co.jp/products/qrh/index.html | ||||

Inquiries

| Personnel / Department | Project Planning & Development Dept. / Deputy director, Hideki Usami | ||||

|---|---|---|---|---|---|

| Address | 158 Kitayama, Morowa, Aichi-gun Togo-cho, Aichi, 470-0151, Japan | ||||

| Contact |

TEL: +81-561-38-6827 FAX: +81-561-38-1218 |

||||

Outline of Company and Organization

| Location | 158 Kitayama, Morowa, Aichi-gun Togo-cho, Aichi, 470-0151 Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-561-38-1211 FAX: +81-561-38-1218 | ||||

| Capital / No. of Employees | 546,850,000 yen・112 employees | ||||

| Product Line | Compressed air/vacuum molding machines and related equipment | ||||

| Major Customers | Daiichi Jitsugyo Co., Ltd. | ||||

| Overseas Base(s) | None | ||||

| Certification | None | ||||

| Company/Organization WEB page | http://www.asano-lab.co.jp/ | ||||

Update date: 2020/2/18