SAKAI OVEX Co., Ltd.

Strength increase, weight reduction, and molding time shortening using carbon fiber opened yarn prepreg impregnated with thermoplastic resin

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ 3D printing ] [ carbon fiber reinforced thermoplastic plastics ] [ Carbon fibers ] [ CFRTP ] [ high-speed molding ] [ opening ] [ tape ] [ weight reduction ]

Point of the Proposed Technology

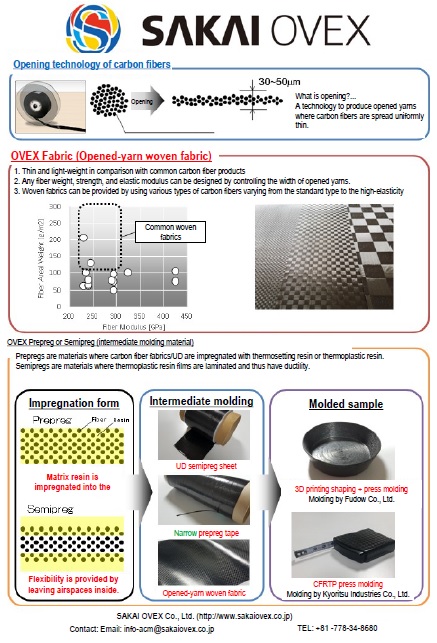

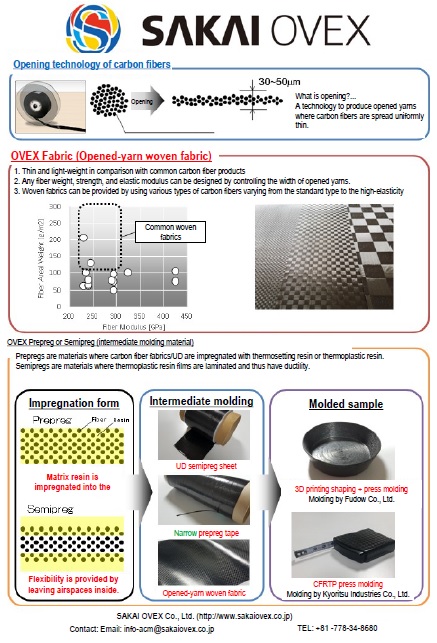

・Various intermediate molding materials were developed by the opening technology for thinly spreading carbon fiber tows as a coretechnology.

・Fabrics using opened carbon fibers and materials molded by using UD have small crimps and high strength properties.

・We propose "OVEX fabric," which is an intermediate molding material with “thickness and weight” reduced to 1/2 or less of the conventional material and "OVEX prepreg," which is an intermediate molding material made by impregnating UD with thermoplastic resin.

・Fabrics using opened carbon fibers and materials molded by using UD have small crimps and high strength properties.

・We propose "OVEX fabric," which is an intermediate molding material with “thickness and weight” reduced to 1/2 or less of the conventional material and "OVEX prepreg," which is an intermediate molding material made by impregnating UD with thermoplastic resin.

Effect(s)

Shortened cycle: 3 hours → severalminutes to tens of minutes

Weight reduction: (thickness 1/2 or less ofthe conventional material)

Higher strength/higher rigidity

Weight reduction: (thickness 1/2 or less ofthe conventional material)

Higher strength/higher rigidity

Conventional Technology

・The 1 layer has the thickness of about 0.1 to 0.2 mm, and thus its degree of freedom in material design is low.

New Technology

・Opened carbon fibers have the 1 layer with the thickness of 0.02 to 0.1 mm, and thus their degrees of freedom in material design are high and it is possible to introduce material design for further weight reduction.

・Thin-layer prepreg tapes using various resins (PA12, PA6, PC, PPS, and PEEK) can be provided.

Technology Deployment and Cooperation

| Development Stage |

Development Stage

(to be completed in 0/0; progress: 80%) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Yes | ||||

| Joint Researchers (their role) | Kanazawa Institute of Technology

|

||||

| Example of Application | ・Automobile parts

・Structural members for aircrafts ・Industrial machinery related parts | ||||

| Technical Problems | ・Establishing a molding technology

・Improving quality and mass production technology | ||||

| Collaborator needed to Improve | ・Companies/universities/research organizations having molding and processing facilities for CFRTP prepreg

・Thermoplastic resin manufacturers | ||||

| Technical WEB page | http://www.sakaiovex.co.jp/square/carbon/index.html | ||||

Inquiries

| Personnel / Department | Technical Center, Advanced Composite Materials Group / Leader, Hiroki Kono | ||||

|---|---|---|---|---|---|

| Address | 20-16 Nishitanaka, Nyugunechizencho, Fukui, 916-0141 Japan | ||||

| Contact |

TEL: +81-778-34-8680 |

||||

Outline of Company and Organization

| Location | 2-15-1 Hanandoh Naka, Fukui-shi, Fukui, 918-8530 Japan | ||||

|---|---|---|---|---|---|

| Capital / No. of Employees | 4,655,040,000 yen・506 employees | ||||

| Product Line | Fiber related products | ||||

| Major Customers | |||||

| Overseas Base(s) | |||||

| Certification | ISO9001, ISO14001 | ||||

| Company/Organization WEB page | http://www.sakaiovex.co.jp/ | ||||

Update date: 2020/1/31