Toyama Industrial Technology Research and Development Center

Dissimilar joining of carbon fiber reinforced thermoplastic to metal by punching

- Technical Classification:

- [ Joining ]

- Products:

- Keyword:

- [ CFRTF ] [ dissimilar joint ] [ punching ]

Point of the Proposed Technology

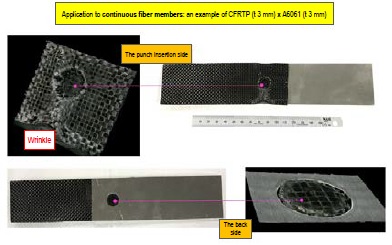

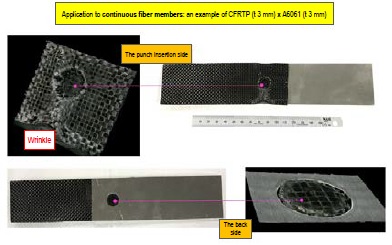

A hole is punctured on the metal side that can be easily processed and CFRTP is inserted there by punching.

・A wrinkle part is formed to insert the continuous fiber member with no ductility without damaging the member.

・It is possible to make reinforcement in the slip-off direction (in cross tensile test) by back burr processing (under study).

・It is possible to make reinforcement by non-circular processing, multi-point processing, etc. (under study)

・A wrinkle part is formed to insert the continuous fiber member with no ductility without damaging the member.

・It is possible to make reinforcement in the slip-off direction (in cross tensile test) by back burr processing (under study).

・It is possible to make reinforcement by non-circular processing, multi-point processing, etc. (under study)

Effect(s)

In terms of direct joining between CFRTP and metal materials:

・Simple and low-cost joining methods

・Generation of inherent strength of fiber-reinforced composite materials to shear direction

・Joining made possible together with forming.

・Short-time processing (joining is possible in about 30 seconds with continuous fiber members and in about one second with injection-molded members)

・Good appearance on injection-molded members (no need to form wrinkle parts)

・Simple and low-cost joining methods

・Generation of inherent strength of fiber-reinforced composite materials to shear direction

・Joining made possible together with forming.

・Short-time processing (joining is possible in about 30 seconds with continuous fiber members and in about one second with injection-molded members)

・Good appearance on injection-molded members (no need to form wrinkle parts)

Conventional Technology

・When using an adhesive agent, strength is controlled by binder materials (the inherent strength of composite materials cannot be used)

・Fastening with bolts requires difficult hole drilling in CFRP and also increases the weight (high costs).

・Fastening with bolts requires difficult hole drilling in CFRP and also increases the weight (high costs).

New Technology

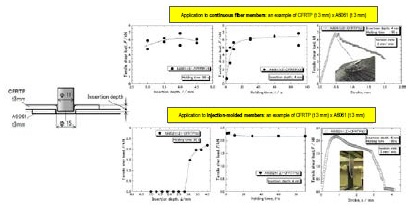

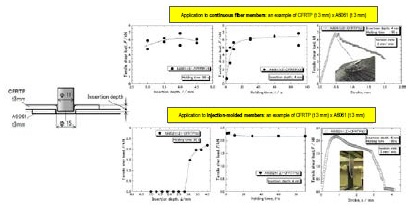

Responding to continuous fibers.

Example of processing conditions and a tensile shearing load

Technology Deployment and Cooperation

| Development Stage |

Prototyping / experimental Stage

(to be completed in 2021/3; progress: 70%) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Applying | ||||

| Joint Researchers (their role) | |||||

| Example of Application | ・Structural members

・Stiffened members (backing of metal with CFRTP) ・Joining machine (multi-jointed robot x type C arm, multi-point die forming), etc. | ||||

| Technical Problems | |||||

| Collaborator needed to Improve | Members/Completed car manufacturers, joining machine manufacturers, etc.

| ||||

| Technical WEB page | |||||

Inquiries

| Personnel / Department | Functional Material Processing Section, Monozukuri Research and Development Center / Hideki Yamagishi | ||||

|---|---|---|---|---|---|

| Address | 150 Futagami-cho, Takaoka-shi, Toyama, 933-0981 Japan | ||||

| Contact |

TEL: +81-766-21-2121 FAX: +81-766-21-2402 |

||||

Outline of Company and Organization

| Location | 150 Futagami-cho, Takaoka-shi, Toyama, 933-0981 Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-766-21-2121 FAX: +81-766-21-2402 | ||||

| Capital / No. of Employees | 0 yen・56 employees | ||||

| Product Line | |||||

| Major Customers | |||||

| Overseas Base(s) | |||||

| Certification | |||||

| Company/Organization WEB page | http://www.itc.pref.toyama.jp/ | ||||

Update date: 2020/1/30