SEIREN CO., LTD./KB SEIREN, LTD.

New-type CFRP prepreg sheets (featured by thermosetting property, opened thin layer, normal temperature storage/world’s fastest hardening)

- Technical Classification:

- [ Intermediate Products ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ Carbon fibers ] [ CFRP ] [ continuous drawing ] [ EPOXY ] [ high cycle ] [ high mechanical strength ] [ high-speed hardening ] [ normal temperature ] [ opening ] [ Prepreg ] [ Press ] [ rapid hardening ] [ thermosetting ] [ thin layer ] [ UD ] [ unidirectional ]

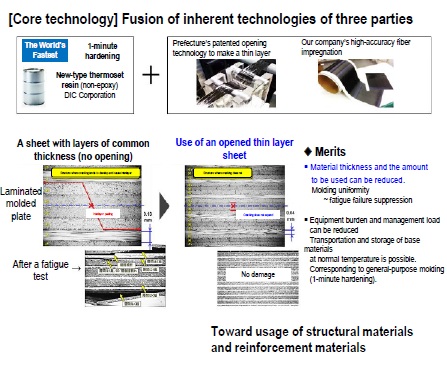

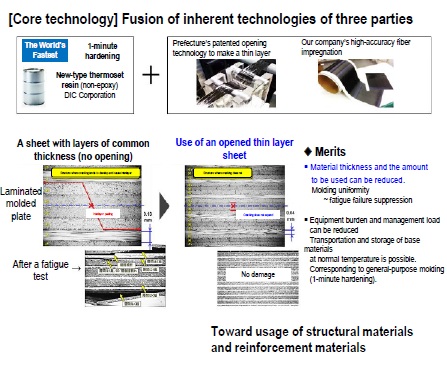

Point of the Proposed Technology

Thin-layer UD base material that is realized by fusion between Fukui Prefecture’s patented opening technology (withthe world best opening rate) and the fiber impregnation technology of our company.

In addition to targeting the epoxy system, the world’s fastest radical hardening type is under development jointly withDIC Corporation.

In addition to targeting the epoxy system, the world’s fastest radical hardening type is under development jointly withDIC Corporation.

Effect(s)

Recommended for reduction of the product material thickness and the material amount tobe used!

It can realize the thinness (ultralight), high mechanical strength, and high rigidity, whichare unable to be realized not only by preforms, woven fabrics, and SMC but also bycommon prepregs.

The high-speed hardening type enables production by general-purpose moldingmachines (with hot press, belt press, continuous drawing, etc.), in addition to normaltemperature storage of base materials, and thus equipment burden and managementload can be suppressed.

It can realize the thinness (ultralight), high mechanical strength, and high rigidity, whichare unable to be realized not only by preforms, woven fabrics, and SMC but also bycommon prepregs.

The high-speed hardening type enables production by general-purpose moldingmachines (with hot press, belt press, continuous drawing, etc.), in addition to normaltemperature storage of base materials, and thus equipment burden and managementload can be suppressed.

Conventional Technology

♦ Drawback

1. Common prepreg base materials often cause molding irregularities and void defects.

2. Increase of base material management workloads (for refrigerated transportation/refrigerated storage)

3. Molding productivity is low (hardening time: 60 minutes).

1. Common prepreg base materials often cause molding irregularities and void defects.

2. Increase of base material management workloads (for refrigerated transportation/refrigerated storage)

3. Molding productivity is low (hardening time: 60 minutes).

New Technology

♦ Advantage

1. This thin-layer prepreg has high molding uniformity and can suppress interlaminar fracture.

2. Transportation and storage at normal temperature is possible.

3. Hot press forming takes just 1 minute, and continuous belt press and continuous drawing are also possible.

1. This thin-layer prepreg has high molding uniformity and can suppress interlaminar fracture.

2. Transportation and storage at normal temperature is possible.

3. Hot press forming takes just 1 minute, and continuous belt press and continuous drawing are also possible.

Technology Deployment and Cooperation

| Development Stage |

Prototyping / experimental Stage

(to be completed in 2021/3; progress: 60%) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Yes | ||||

| Joint Researchers (their role) | ・Industrial Technology Center of Fukui Prefecture (patented opening technology)

・DIC Corporation (development of chemicals) ・Our company (development of processes) |

||||

| Example of Application | There are many requests, as shown below, from forming and product manufacturers of high-strength thin members where thin layers are effective.

1. Reduction of thickness and the amount to be used because it allows to make materials stronger and harder than other base materials. 2. Reduction, as much as possible, of equipment cost and management workload in material storage, forming process, etc. | ||||

| Technical Problems | It is currently in the development phase of manufacturing processes with dedicated pilot lines, and simultaneously the development of the following base materials for specific users is underway.

If samples are requested, we can respond only by simple information exchange on usage fields, delivery dates, result feedback, etc. Fiscal 2019: Made of 40 to 150 μm (thickness) × max. 25 cm (width) × 100 m (length to be wound), etc. After fiscal 2020: Made of 40 to 150 μm (thickness) × max. 50 cm (width) × several 100 m (length to be wound), width slit can be accepted, and individually customized | ||||

| Collaborator needed to Improve | We'd like to collaborate with additional businesses in the following categories for supply of prepregs by use of pilot lines from fiscal 2021.

1. Businesses having technologies varying from prepreg lamination to press forming or continuous forming technology. 2. Businesses which develop composites for high-strength usage where thin layers can be effectively applied. | ||||

| Technical WEB page | |||||

Inquiries

| Personnel / Department | R&D Center / Manager, Akihiro Nogata | ||||

|---|---|---|---|---|---|

| Address | 48-113-2 Mikunichoyonozu, Sakai-shi, Fukui, 913-0036 Japan | ||||

| Contact |

TEL: 0776-50-7009 |

||||

Outline of Company and Organization

| Location | 1-10-1 Keya, Fukui-shi, Fukui, 918-8560 Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-776-35-2111 FAX: +81-776-35-2114 | ||||

| Capital / No. of Employees | 17,520,250,000 yen・1608 employees | ||||

| Product Line | Fiber products, industrial chemical products, industrial equipment, electronic parts | ||||

| Major Customers | |||||

| Overseas Base(s) | USA, China, Thailand, India, Indonesia, Brasil, Mexico | ||||

| Certification | |||||

| Company/Organization WEB page | http://www.seiren.com/ | ||||

Update date: 2020/1/31