NACHI-FUJIKOSHI.CORP

Extension of life of CFRP hole-processing drill by crystal diamond coating

- Technical Classification:

- [ Processing ]

- Products:

- [ Jig ]

- Keyword:

- [ CFRP hole-processing ] [ control of delamination ] [ extension of tool life ]

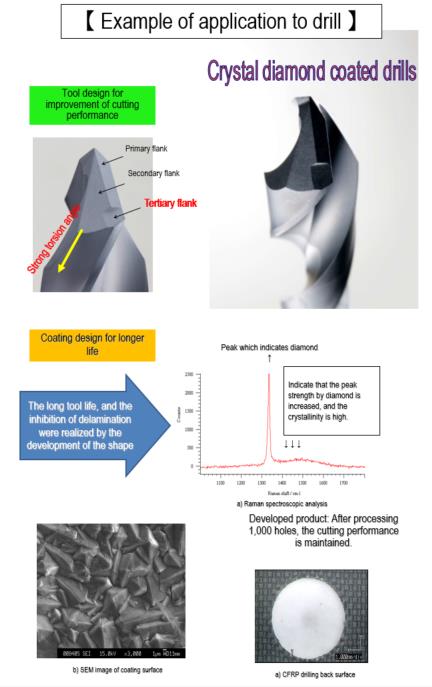

Point of the Proposed Technology

- In cutting of carbon composite fibers (CFRP) with high strength and high opponent attacking property, the tool life will be improved greatly compared to the conventional diamond coating by adoption of the crystal diamond coating with higher crystalline and improved wear resistance.

Effect(s)

Tool life (more than twice the conventional product)

Control of residual fibers and delamination

Control of residual fibers and delamination

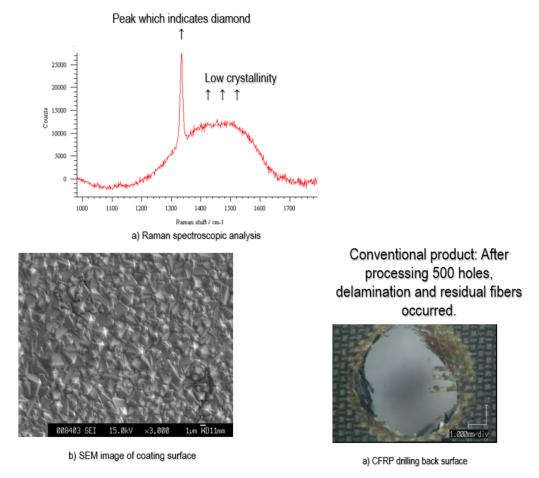

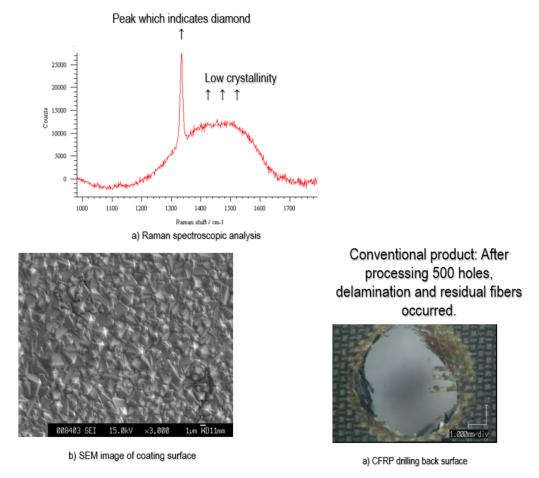

Conventional Technology

【Example of application to drill】

Problem of CFRP (carbon fiber reinforced plastics) processing

CFRP = Carbon Fiber Reinforced Plastics

New material of carbon fiber fabrics layered and hardened with resin

1) Wear progresses quickly.

- Hard carbon fiber: 6,000 to 8,000 HV

⇒ For the conventional diamond coating, wear progresses quickly and the life is short.

2) Delamination and residual fibers occur easily.

- If the tool does not cut well, laminated carbon fibers will not be cut, and delamination or residual fibers will occur, resulting in quality defect.

3) Weak against heat

- The heat resisting temperature of resin is about 200℃:

The processing heat cannot be increased.

⇒ A sharp cutting blade excellent in cutting performance with low resistance is necessary.

Problem of CFRP (carbon fiber reinforced plastics) processing

CFRP = Carbon Fiber Reinforced Plastics

New material of carbon fiber fabrics layered and hardened with resin

1) Wear progresses quickly.

- Hard carbon fiber: 6,000 to 8,000 HV

⇒ For the conventional diamond coating, wear progresses quickly and the life is short.

2) Delamination and residual fibers occur easily.

- If the tool does not cut well, laminated carbon fibers will not be cut, and delamination or residual fibers will occur, resulting in quality defect.

3) Weak against heat

- The heat resisting temperature of resin is about 200℃:

The processing heat cannot be increased.

⇒ A sharp cutting blade excellent in cutting performance with low resistance is necessary.

New Technology

Technology Deployment and Cooperation

| Development Stage |

Commercialization Completed (already delivered: yes) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Yes | ||||

| Joint Researchers (their role) | Nippon Institute of Technology (Coating film performance evaluation)

|

||||

| Example of Application | Airframe parts using CFRP of aircraft

| ||||

| Technical Problems | - Tool shape may be studied according to processing and required accuracy for each user.

- Once the film removal, regrinding, and recoating technologies for diamond coating tools are established, it will contribute further to the cost reduction of users. | ||||

| Collaborator needed to Improve | |||||

| Technical WEB page | http://www.nachi-fujikoshi.co.jp/tool/drill/crystal-dia_a.htm | ||||

Inquiries

| Personnel / Department | Technology Development Round Tool Technology Development Section,Engineering Dept., Cutting Tool Division / Shinichirou Oono | ||||

|---|---|---|---|---|---|

| Address | 1-1-1, Fujikoshi-Honmachi, Toyama, 930-8511, JAPAN | ||||

| Contact |

TEL: +81-76-423-5104 |

||||

Outline of Company and Organization

| Location | Shiodome Sumitomo Bldg. 17F, 1-9-2 Higashi-Shinbashi, Minato-ku, Tokyo 105-0021,Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-3-5568-5240 FAX: +81-3-5568-5236 | ||||

| Capital / No. of Employees | 16,000,000,000 yen・3147 employees (Non-Consolidated) | ||||

| Product Line | Cutting tools, bearings, hydraulic robots, steel products, etc. | ||||

| Major Customers | Automobile manufacturers, heavy industries manufacturers | ||||

| Overseas Base(s) | United States, China, Brazil, Thailand, etc. | ||||

| Certification | ISO9001、ISO14001 | ||||

| Company/Organization WEB page | http://www.nachi-fujikoshi.co.jp/ | ||||

Update date: 2020/2/2