Suruga Engineering Inc.

Shortening of the molding time and improvement of the surface quality by adopting a CFRTP hybrid press molding die

- Technical Classification:

- [ Molding ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

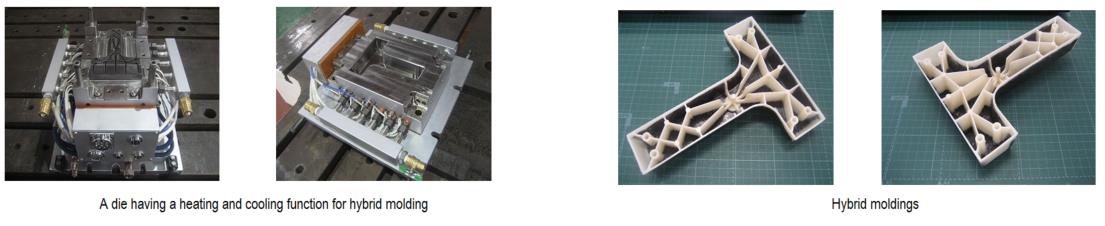

- [ A hybrid molding die ] [ heating and cooling molding ] [ optimization of the molding conditions ]

Point of the Proposed Technology

Shortening of the molding time by shifting from thermosetting resign molding to thermoplastic molding.

Contributing to cost reduction since preforming and injection are performed in one process, and the undercut, rib and boss shapes can be formed simultaneously.

Quality improvement of the product design surface through heating and cooling molding.

Contributing to cost reduction since preforming and injection are performed in one process, and the undercut, rib and boss shapes can be formed simultaneously.

Quality improvement of the product design surface through heating and cooling molding.

Effect(s)

Molding cycle: 5 minutes → 1 minute

Cost for assembling other parts can be eliminated

Cost for assembling other parts can be eliminated

Conventional Technology

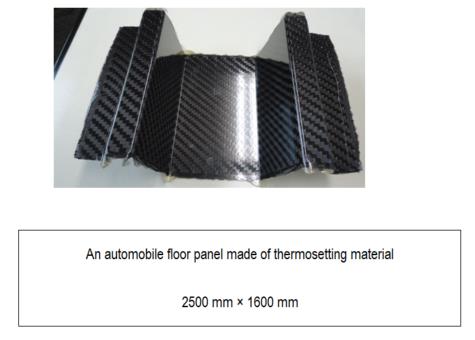

Previously, products made of thermosetting materials represented a majority of products requiring strength and design.

The biggest advantage of products made of thermosetting materials is that the surface of the molding can be used as the design surface as-is.

However, they have disadvantages such as a long molding cycle, a poor product yield, and the need for assembling other parts for the rib, boss and undercut shapes.

An increasing number of products have shifted to thermoplastic materials, though not all.

The biggest advantage of products made of thermosetting materials is that the surface of the molding can be used as the design surface as-is.

However, they have disadvantages such as a long molding cycle, a poor product yield, and the need for assembling other parts for the rib, boss and undercut shapes.

An increasing number of products have shifted to thermoplastic materials, though not all.

New Technology

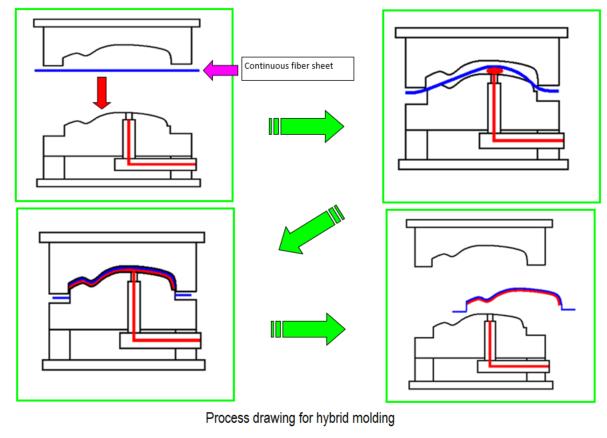

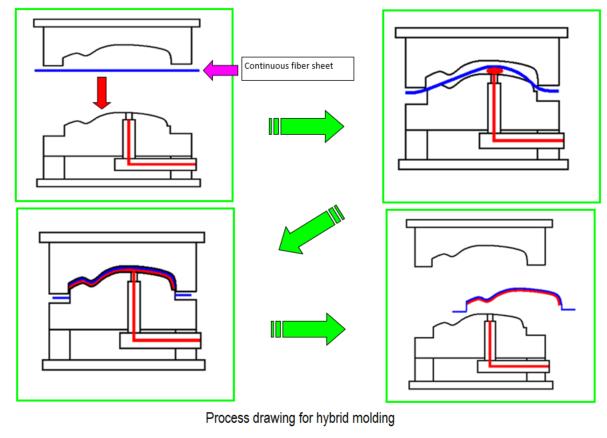

One of the advantages of thermoplastic hybrid molding is that the molding cycle can be shortened since preforming and molding can be performed in one process with a cycle equivalent to resin-only molding.

Since the process is injection molding, the rib shape as well as the boss shape and the undercut shape can be simultaneously formed for any part having insufficient strength. A post-process assembly can be eliminated.

The quality of the design surface is currently inferior to that of thermosetting material. The company is pursuing the development aimed at achieving a product at the highest possible level by using heating and cooling molding technology.

Since the process is injection molding, the rib shape as well as the boss shape and the undercut shape can be simultaneously formed for any part having insufficient strength. A post-process assembly can be eliminated.

The quality of the design surface is currently inferior to that of thermosetting material. The company is pursuing the development aimed at achieving a product at the highest possible level by using heating and cooling molding technology.

Technology Deployment and Cooperation

| Development Stage |

Commercialization Completed (already delivered: yes) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Yes | ||||

| Joint Researchers (their role) | Die structure: Our company's own technology

Material manufacturers Molding equipment manufacturers Auxiliary equipment manufacturers |

||||

| Example of Application | Automotive parts, aircraft parts, railway car parts, parts for housing building materials

| ||||

| Technical Problems | Shortening of the molding cycle in the heating and cooling process, reduction of temperature variations, development to new items

| ||||

| Collaborator needed to Improve | Customers that would consider development/mass production of parts using the hybrid molding technology

Material manufacturers, equipment manufacturers, research institutes such as universities that would collaborate with us | ||||

| Technical WEB page | http://www.marusun-g.co.jp/ | ||||

Inquiries

| Personnel / Department | Development technology / Manager, Kazuya Oshiba | ||||

|---|---|---|---|---|---|

| Address | 652-1, Hananoki, Imaizumi, Fuji-city , Shizuoka Pref, 417-0001, Japan | ||||

| Contact |

TEL: +81-545-51-5221 FAX: +81-545-53-1396 |

||||

Outline of Company and Organization

| Location | 652-1, Hananoki, Imaizumi, Fuji-city , Shizuoka Pref, 417-0001, Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-545-51-5221 FAX: +81-545-53-1396 | ||||

| Capital / No. of Employees | 69,150,000 yen・81 employees | ||||

| Product Line | Die design, manufacturing, prototyping | ||||

| Major Customers | Automobile manufacturers, aircraft manufacturers, parts manufacturers | ||||

| Overseas Base(s) | None | ||||

| Certification | ISO9001 / ISO14000 (acquired by the head office) | ||||

| Company/Organization WEB page | http://www.marusun-g.co.jp/ | ||||

Update date: 2020/2/1