Takagi Seiko Corporation

Weight reduction of structural parts by thermoplastic resin composite materials

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ Compatible ] [ productivity ] [ resin structural parts ] [ strength ]

Point of the Proposed Technology

Resin is increasingly adopted for aircraft and luxury cars for the purpose of the weight reduction of conventional metal structural parts.

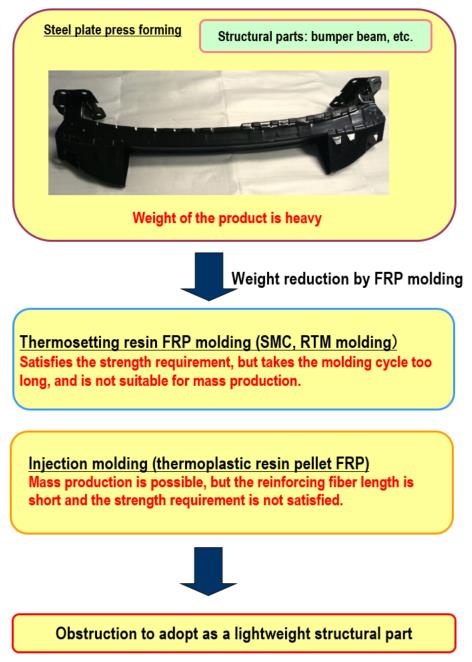

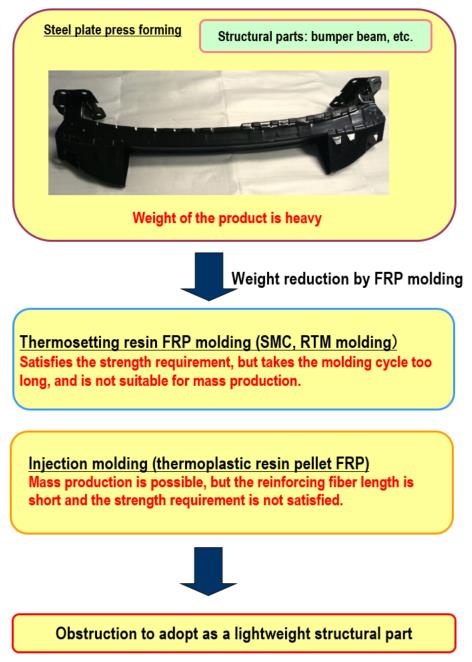

Thermosetting resin composite materials are inferior in productivity and are limited to be applicable to small production parts.

Our company has established a molding technology for thermoplastic resin composite material with excellent productivity and realized stable high-speed molding in order to overcome this issue.

Thermosetting resin composite materials are inferior in productivity and are limited to be applicable to small production parts.

Our company has established a molding technology for thermoplastic resin composite material with excellent productivity and realized stable high-speed molding in order to overcome this issue.

Effect(s)

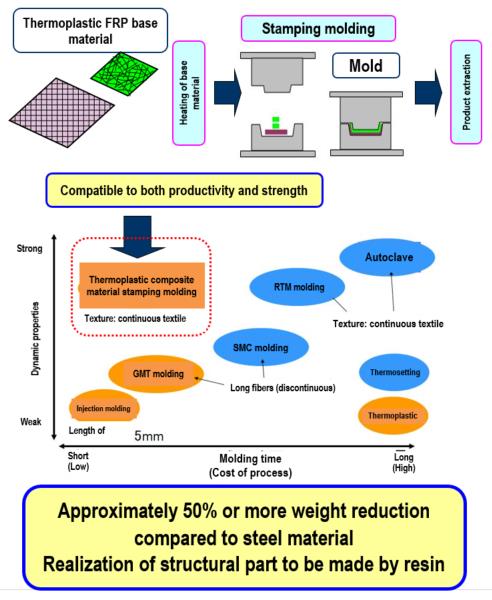

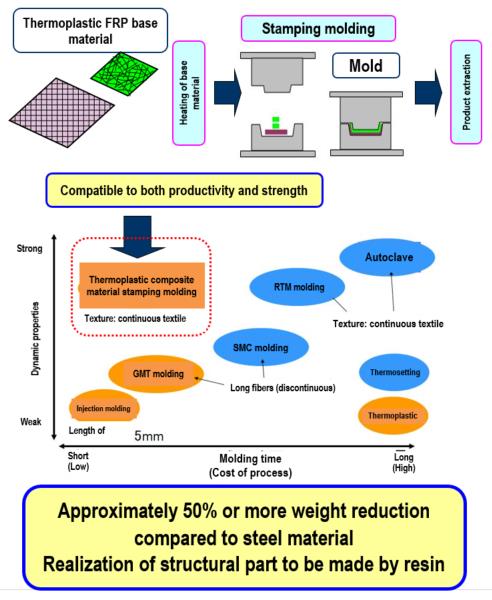

Approximately 50% weight reduction compare to steel

Production is possible to correspond with automobile production line speed

Production is possible to correspond with automobile production line speed

Conventional Technology

Problems of the conventional construction method in structural component manufacturing

New Technology

Development of high-speed stamping molding method for thermoplastic resin composite material

・Mass production is possible with the same molding cycle as injection molding.

・Product strength is secured with a combination of continuous textile reinforcing fibers.

・High precision molding is realized by a fully automated manufacturing process.

・Degree of freedom of shape in product design is high, such as gradually changing the thickness of the product, rib settings, etc.

・The use of thermoplastic resin allows product recycling.

・Mass production is possible with the same molding cycle as injection molding.

・Product strength is secured with a combination of continuous textile reinforcing fibers.

・High precision molding is realized by a fully automated manufacturing process.

・Degree of freedom of shape in product design is high, such as gradually changing the thickness of the product, rib settings, etc.

・The use of thermoplastic resin allows product recycling.

Technology Deployment and Cooperation

| Development Stage |

Commercialization Completed (already delivered: yes) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Applying | ||||

| Joint Researchers (their role) | Automobile manufacturers (structural part design and evaluation)

|

||||

| Example of Application | Structural components of automobiles (bumper beams, etc.)

Structural components for construction, etc. | ||||

| Technical Problems | Technical challenge: handling of multi materials (different-material bonding, etc.), development of a high-speed nondestructive inspection system, etc.

| ||||

| Collaborator needed to Improve | Molding material manufacturer, machine equipment manufacturer, downstream manufacturer (automobile, construction, etc.)

| ||||

| Technical WEB page | https://www.takagi-seiko.co.jp/technology/ | ||||

Inquiries

| Personnel / Department | Composite Product Development Group, Advanced Technology Development Center / Nobutada Takahashi | ||||

|---|---|---|---|---|---|

| Address | 322-3, Futazuka, Takaoka-shi, Toyama, 933-8628 Japan | ||||

| Contact |

TEL: +81-766-84-2318 |

||||

Outline of Company and Organization

| Location | 322-3, Futazuka, Takaoka-shi, Toyama, 933-8628 Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-766-24-5522 FAX: +81-766-25-8309 | ||||

| Capital / No. of Employees | 2,104,900,000 yen・895 employees | ||||

| Product Line | Manufacturing and sale of plastic moldings and molds | ||||

| Major Customers | Honda Motor Co., Ltd., SUZUKI MOTOR CORPORATION, FUJITSU, etc. | ||||

| Overseas Base(s) | China, Indonesia, Thailand | ||||

| Certification | ISO9001 ISO14001 | ||||

| Company/Organization WEB page | http://www.takagi-seiko.co.jp | ||||

Update date: 2020/2/2