Hirose mold co., ltd

Molding of motor core using magnetic material-added CFRP

- Technical Classification:

- [ Molding ]

- Products:

- [ Products / Processed Products ]

- Keyword:

- [ cutting ] [ die processing ] [ Magnetic material-added CFRP ] [ press molding ]

Point of the Proposed Technology

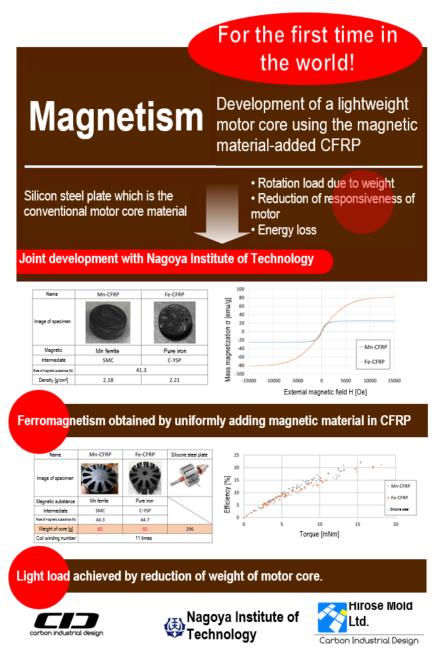

Development of the magnetic material-added CFRP with magnetic substance added inside it

Using the magnetic material-added CFRP, a motor core is formed. Compared to the conventional motor core of silicon steel plate, more weight is reduced.

Using the magnetic material-added CFRP, a motor core is formed. Compared to the conventional motor core of silicon steel plate, more weight is reduced.

Effect(s)

The uniform addition of magnetic material in CFRP achieves ferromagnetism and reduced weight, resulting in reduction of load.

Conventional Technology

Through the manufacturing of thermosetting CFRP parts by CFRP cutting technology (Photo 1) and the manufacturing and selling of the carbon shoehorn which was made by the simplified press molding of a soft CFRP material before heat curing which is a thin-plate form material of SMC (Sheet Molding Compound) (Photo 2), we have cultivated the know-how about CFRP.

New Technology

Using the know-how, we successfully developed, in the joint research with Nagoya Institute of Technology, the "magnetic material-added CFRP" with magnetic material added to CFRP itself to impart ferromagnetism. The motor core formed using the magnetic material-added CFRP (Photo 3, left: conventional silicone steel plate, middle: manganese ferrite added, right: pure iron added) is lightweight compared to the conventional motor core of silicon steel plate, allowing reduction of rotation load due to weight, reduction of motor responsiveness and energy loss. The motor core formed using the magnetic material-added CFRP was developed for the first time in the world, and it is the latest technology that will be widely applied in various fields in the future.

Technology Deployment and Cooperation

| Development Stage |

Development Stage

(to be completed in 0/0; progress: 0%) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | None | ||||

| Joint Researchers (their role) | Nagoya Institute of Technology

|

||||

| Example of Application | Motor core

| ||||

| Technical Problems | Small-scale high precision molding with press die

| ||||

| Collaborator needed to Improve | |||||

| Technical WEB page | https://hirose-mold.com/top/magnetic_cfrp_motorcore | ||||

Inquiries

| Personnel / Department | CFRP gr. / Operating officer, Keisuke Yamane | ||||

|---|---|---|---|---|---|

| Address | 1469-3 Inabeminamino Kamono-cho, Minokamo-city, Gifu, 505-0055 Japan | ||||

| Contact |

TEL: +81-574-25-0717 FAX: +81-574-25-0664 |

||||

Outline of Company and Organization

| Location | 1469-3 Inabeminamino Kamono-cho, Minokamo-city, Gifu, 505-0055 Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-574-25-0717 FAX: +81-574-25-0664 | ||||

| Capital / No. of Employees | 5,000,000 yen・4 employees | ||||

| Product Line | Die-cast molds | ||||

| Major Customers | Shin Tokai Die Casting Industry Ltd. | ||||

| Overseas Base(s) | None | ||||

| Certification | なし | ||||

| Company/Organization WEB page | https://hirose-mold.com/ | ||||

Update date: 2020/2/2