Hitachi Zosen Fukui Corporation

Mechanical/hydraulic hybrid two-sided CFRTP molding machine

- Technical Classification:

- [ Molding ]

- Products:

- [ Equipment / Facilities ]

- Keyword:

- [ 2-sided ] [ high-speed ] [ holding ] [ molding ] [ opening/closing ] [ Press ] [ pressure ] [ Thermoplastic ]

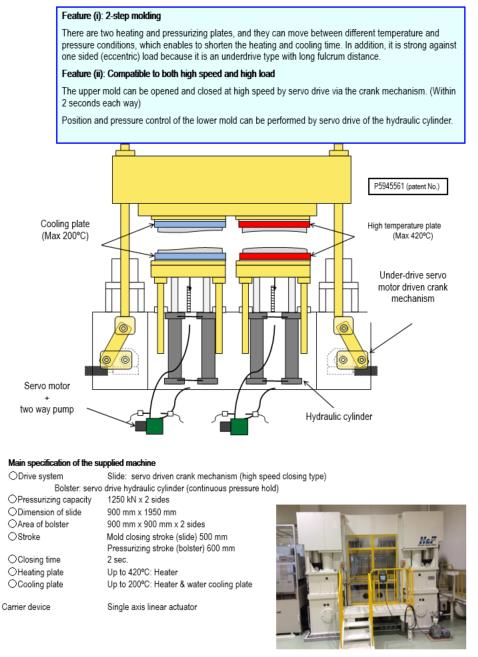

Point of the Proposed Technology

Including two pressure plate surfaces, each of which can be set to different temperatures and different pressures (420ºC Max)

The holding pressure and position can be controlled by mechanical servomechanism, while realizing high-speed mold opening and closing and bottom dead center accuracy. And also no restriction on pressurization holding time

Suitable eccentric load and minimum machine height due to underdrive mechanism

The holding pressure and position can be controlled by mechanical servomechanism, while realizing high-speed mold opening and closing and bottom dead center accuracy. And also no restriction on pressurization holding time

Suitable eccentric load and minimum machine height due to underdrive mechanism

Effect(s)

Capable to correspond with various construction methods using CFRTP material which will draw attention in the future

Conventional Technology

Machine presses that are good at high-speed mass production are not suitable for resin molding because of the weak pressure holding control.

However, for a hydraulic press suitable for holding pressure,

・It is inevitable to increase the scale of the equipment in order to increase the speed.

・A special mechanism is required to maintain the parallelism against eccentric load.

・Maintenance is difficult due to the need of a large amount of oil.

As stated above, there are many disadvantages in constructing high-speed mass production systems.

However, for a hydraulic press suitable for holding pressure,

・It is inevitable to increase the scale of the equipment in order to increase the speed.

・A special mechanism is required to maintain the parallelism against eccentric load.

・Maintenance is difficult due to the need of a large amount of oil.

As stated above, there are many disadvantages in constructing high-speed mass production systems.

New Technology

We propose a press equipment combining mechanical and hydraulic advantages.

・Realizes high-speed mold opening and closing, high bottom dead center accuracy and reproducibility by mechanical servomechanism,

・Hydraulic servo mechanism enables holding pressure control and position control. And no retention time limit.

・Realizes high-speed mold opening and closing, high bottom dead center accuracy and reproducibility by mechanical servomechanism,

・Hydraulic servo mechanism enables holding pressure control and position control. And no retention time limit.

Technology Deployment and Cooperation

| Development Stage |

Commercialization Completed (already delivered: yes) |

||||

|---|---|---|---|---|---|

| Intellectual Property Right | Yes | ||||

| Joint Researchers (their role) | Industrial Technology Center of Fukui Prefecture

|

||||

| Example of Application | Weight reduction for car body parts

| ||||

| Technical Problems | Develop a high productivity CFRP production equipment utilizing large machine press manufacturing and high speed automatic transfer technology, and aim to enter the automotive CFRP press production equipment field.

| ||||

| Collaborator needed to Improve | CFRP press die manufacturers, CFRP material manufacturers, and CFRTP product manufacturers (facility users) who are considering equipment for development and mass production

| ||||

| Technical WEB page | http://www.h-f.co.jp/publics/index/207/ | ||||

Inquiries

| Personnel / Department | Technical Headquarters Technical Development Section / Kenji Nishida | ||||

|---|---|---|---|---|---|

| Address | 8-28, Jiyugaoka 1-chome, Awara-city, Fukui-pref., 919-0695, Japan | ||||

| Contact |

TEL: +81-776-73-1250 |

||||

Outline of Company and Organization

| Location | 8-28, Jiyugaoka 1-chome, Awara-city, Fukui-pref., 919-0695, Japan | ||||

|---|---|---|---|---|---|

| Contact | TEL: +81-776-73-1220 FAX: +81-776-73-3055 | ||||

| Capital / No. of Employees | 1,055,000,000 yen・402 employees | ||||

| Product Line | Sheet metal press machine and peripheral automation equipment | ||||

| Major Customers | Domestic and overseas automobile and auto parts manufacturers | ||||

| Overseas Base(s) | USA, UK, Malaysia, Thailand, China, India, Indonesia, Mexico | ||||

| Certification | ISO 9001,14001 | ||||

| Company/Organization WEB page | http://www.h-f.co.jp/ | ||||

Update date: 2020/2/1